NASA’s future in fuels will see less heavy metal. Literally.

The agency just finished testing on a composite propellant tank that holds cryogenics, or super-chilled gases that are commonly used as rocket fuel (such as for the space shuttle). The agency brought the test tank down to -423 degrees Fahrenheit, put it through a few cycles and ramped up the internal pressure.

Composites are lighter material than the traditional metals that are used to hold these gases. NASA is excitedly throwing out descriptors such as “game-changing” when it talks about this, and has some reason to do so: composites are lighter than metals.

The light weight of composite tanks makes them lighter to lift off the ground. This reduces the costs of launch, which in turn reduces the overall cost of a mission. That will make penny-counters at the agency happier as the agency battles for funding dollars in fiscal 2014 and beyond.

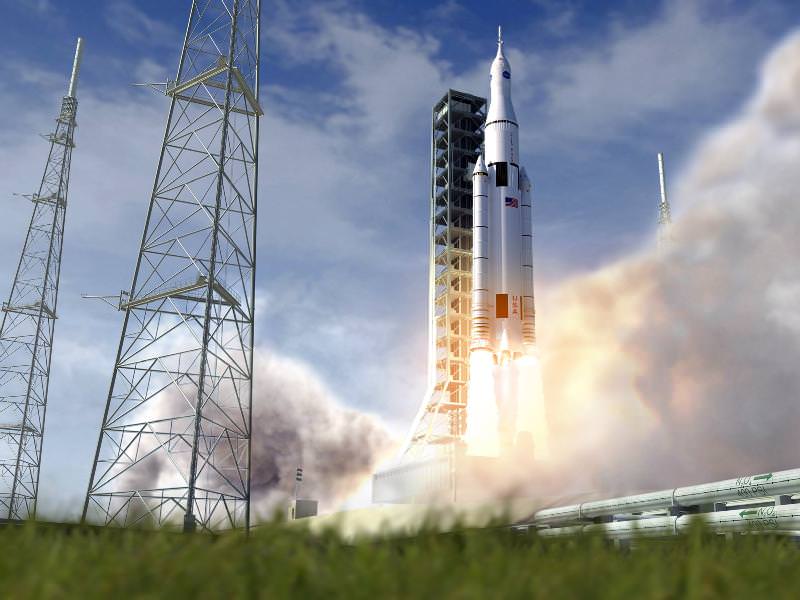

The first of these tanks is likely to be used in the upper stage of NASA’s Space Launch System rocket, which is under development right now. That’s the rocket that’s supposed to send the Orion spacecraft (aiming for a 2014 test flight) into space in the latter years of this decade.

“The tank manufacturing process represents a number of industry breakthroughs, including automated fiber placement of oven-cured materials, fiber placement of an all-composite tank wall design that is leak-tight, and a tooling approach that eliminates heavy joints,” stated Dan Rivera, the Boeing cryogenic tank program manager at Marshall.

Boeing and NASA are now working on another composite tank that should be tested at Marshall later in 2013.

Source: NASA

So they are Carbon composites? epoxy binders?

Another advantage to seamless (no joints) manufacture is quick design to manufacture turnaround.

They have the potential to be literally designed and made the same day.

No shortage of Carbon anytime soon.

i believe quality carbon comes at a price just as quality silicon does. Both are common, it is true, but the first solar cells were made from reject boules of highly refined semiconductor grade silicon.This was way back in the sixties and the company went on to become the finest space grade cell manufacturer.

well they don’t really say if it’s Carbon or fiberglass or what.

i am just guessing.

it’s going to hold cryogenic materials, so..

Could you use metric units in your articles?

Google “-423 fahrenheit in celsius” .. altho I don’t think that’s really necessary. -423F or -253C are both unimaginably cold.

Are you saying there’s a limit on my imagination?

Agree. Scientists worldwide, including the ones in the US, use the metric

system. I’m sure that the results from this test were actually created in

metric and then converted into imperial for the backwards American masses.

Disagree. It’s high-time the rest of the world caught up with our advanced system of feet and inches!

Do these new composite tanks cost less than the metal tanks including the extra fuel needed to lift the heavier metal tanks? Lighter tanks used on non-reuseable rockets are not better if they cost more than the metal tanks we use now plus the extra fuel. Lighter tanks even if they are more expensive would be cost effective if they were reusable though. The article only says that these tanks are lighter and require less fuel, it doesn’t compare the overall cost between the lighter composite tank (using less fuel) to the metal tank (that uses more fuel). The metal tank could be substantially cheaper to make which would more than offset the fuel costs. Fuel is relatively cheap even though rockets burn a lot of it in a short period of time. This is why SpaceX Grasshopper would be such a big deal because it reuses the most expensive component of the system (the rocket), not the fuel.

Agreed, I think the main use would be as tanks on BEO missions including fuel stations. Here the saved weight would likely recoup the added cost. (Until NASA has a reusable launcher, in which case the ROI balance shifts again.)

“40 percent weight savings and a 25 percent cost savings over state-of-the-art metallic tanks.”

“The light weight of composite tanks makes them lighter to lift off the ground. This reduces the costs of launch, which in turn reduces the overall cost of a mission. ”

More likely to use that extra capacity to load on more payload, but it’s still better to load more payload than to have to waste propellant on the launch system.

It’s not just less weight, its also more reactants, which in turn is either heavier load or higher orbit.

Hmm, Skunkwoks tried composite tanks with their Venture Star prototype. When they pressure tested the tank it passed the test all right but when they depressurized the tank it… effectively got The Bends (decompression sickness).

Microscopic pressurized gas molecules permeated the tank’s skin and when the pressure was released the material was fractured.

I hope NASA know all about this and has learned something new to get around the problem!

A 40 percent weight savings over a Al-Li tank? That ain’t bad.