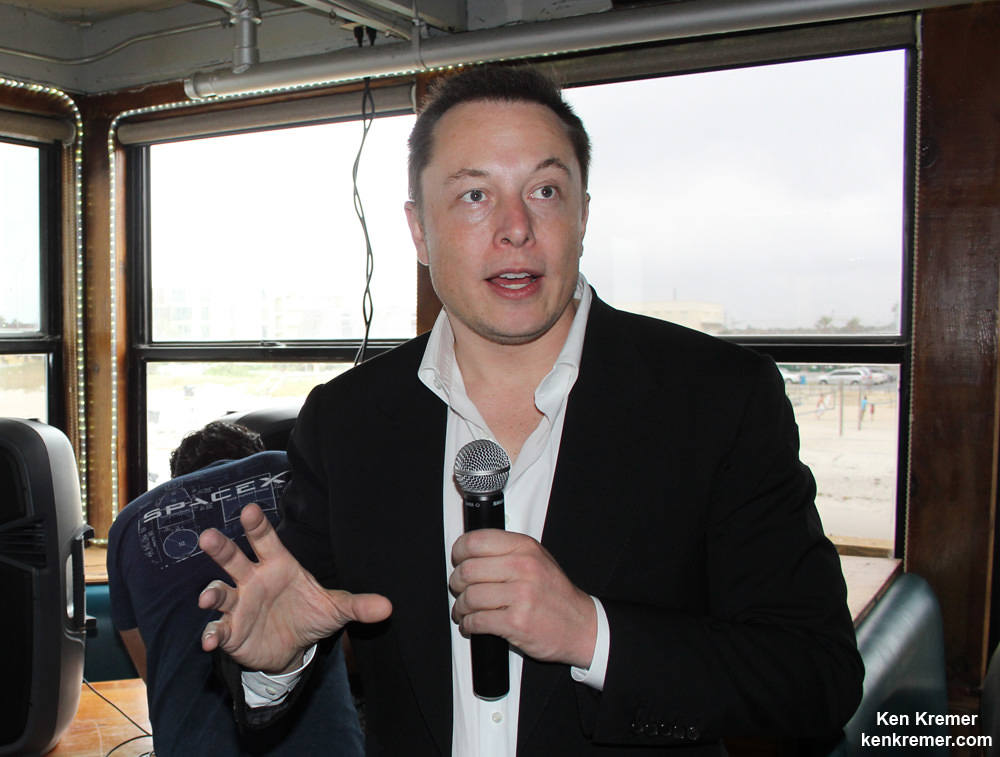

The in-flight failure of a critical support strut inside the second stage liquid oxygen tank holding a high pressure helium tank in the Falcon 9 rocket, is the likely cause of the failed SpaceX launch three weeks ago on June 28, revealed SpaceX CEO and chief designer Elon Musk during a briefing for reporters held today, July 20, to explain why the critical cargo delivery run for NASA to the space station suddenly turned into a total disaster after a promising start.

The commercial booster and its cargo Dragon payload were unexpectedly destroyed by an overpressure event 139 seconds after a picture perfect blastoff from Space Launch Complex 40 at Cape Canaveral Air Force Station in Florida on June 28 at 10:21 a.m. EDT.

Musk emphasized that the failure analysis is still “preliminary” and an “initial assessment” based on the investigation thus far. SpaceX has led the investigation efforts under the oversight of the FAA with participation from prime customers NASA and the U.S. Air Force.

The root cause appears to be that the second stage strut holding the high pressure helium tank inside the 2nd stage broke at a bolt – far below its design specification and thereby allowing the tank to break free and swing away.

“The strut that we believe failed was designed and certified to handle 10,000 lbs of force, but failed at 2,000 lbs, a five-fold difference,” Musk explained.

“During acceleration of the rocket to 3.2 G’s, the strut holding down the helium tank failed. Helium was released, causing the over pressurization event.”

To date no other issues have been identified as possible failure modes, Musk elaborated.

The helium tanks are pressurized to 5500 psi and were breached during the over pressurization. The purpose of the helium tanks is to pressurize the first and second stage propellant tanks.

“We tested several hundred struts. On the outside they looked normal. But inside there was a problem,” Musk explained

“Detailed close-out photos of stage construction show no visible flaws or damage of any kind,” according to a SpaceX statement.

The struts are produced by an outside vendor that Musk would not identify. He added that in the future, SpaceX will likely choose a different vendor to manufacture the struts.

He said the struts were made from a type of stainless steel and would also likely be redesigned.

“The material of construction will be changed to Inconel,” Musk told me in response to a question.

Hundreds of the original type struts have been used to date on the first and second stages of the Falcon 9 with no issues. In the future, they will also be independently certified for use, by an outside contractor instead of the vendor.

The nine first stage Merlin 1D engines of the Falcon 9 were still firing nominally during the start of the mishap, said Musk. The first stage had nearly completed its planned firing duration when the explosion took place.

“The event happened very quickly, within 0.893 seconds,” Musk stated, from the first indication of an issue to loss of all telemetry.

“Preliminary analysis suggests the overpressure event in the upper stage liquid oxygen tank was initiated by a flawed piece of support hardware (a “strut”) inside the second stage,” noted SpaceX in a statement.

Video caption: Launch video of the CRS-7 launch on June 28, 2015 from a remote camera placed at Launch Complex 40. The launch would fail around two minutes later. Credit: Alex Polimeni/Spaceflight Now

The blastoff of the Dragon CRS-7 cargo mission for NASA was the first failure of the SpaceX Falcon 9 rocket after 18 straight successes and the firms first launch mishap since the failure of a Falcon 1 in 2008.

The SpaceX CRS-7 Dragon was loaded with over 4,000 pounds (1987 kg) of research experiments, an EVA spacesuit, water filtration equipment, spare parts, gear, computer equipment, high pressure tanks of oxygen and nitrogen supply gases, food, water and clothing for the astronaut and cosmonaut crews comprising Expeditions 44 and 45.

The Dragon cargo freighter survived the explosion but was destroyed when it impacted the Atlantic Ocean.

“But the Dragon might have been saved if the parachutes had been deployed,” said Musk.

Unfortunately the software required to deploy the parachute was not loaded onboard.

“The new software required to deploy the parachutes will be included on all future Dragons, V1 and V2,” said Musk, referring to the cargo and crew versions of the SpaceX Dragon spaceship.

The NASA cargo was valued at about $110 million. The launch itself was not insured.

The investigation board is reviewing data from over 3,000 telemetry channels as well as video and physical debris, he noted.

The next launch of a Falcon 9 will be postponed at least a few months until “no earlier than September” Musk indicated.

Two Falcon 9 launches had been set for August from Vandenberg AFB and Cape Canaveral. And the next launch to the ISS had been slated for September on the Dragon CRS-8 mission.

Musk said the next payload to be launched aboard a Falcon 9 has yet to be determined.

Starting in 2017, the Falcon 9 will launch astronauts to the ISS aboard the Crew Dragon.

Overall CRS-7 was the seventh SpaceX commercial resupply services mission and the eighth trip by a Dragon spacecraft to the station since 2012.

CRS-7 marked the company’s seventh operational resupply mission to the ISS under a $1.6 Billion contract with NASA to deliver 20,000 kg (44,000 pounds) of cargo to the station during a dozen Dragon cargo spacecraft flights through 2016 under NASA’s original Commercial Resupply Services (CRS) contract.

Stay tuned here for Ken’s continuing Earth and planetary science and human spaceflight news.

………….

Learn more about SpaceX, ULA, Mars rovers, Orion, Antares, MMS, NASA missions and more at Ken’s upcoming outreach events:

July 21/22: “SpaceX, Orion, Commercial crew, Curiosity explores Mars, MMS, Antares and more,” Kennedy Space Center Quality Inn, Titusville, FL, evenings/afternoon for July 22 Delta IV launch of USAF WGS-7 satellite

#include standard jokes about Kerbal Space Program and struts.

I do not at all understand why the software for the parachute rescue system was not loaded… Just stupid or a costly oversight.

If this would happen when astronauts are on board would one not want to have some redundancy and fail safe mechanisms on board??? Why in such scenario the dragon did not fire the escape engines I do not understand.

I view every single lift-off a test for all systems.

“struts not individually certified”, haha

Tay… on previous flights of the Falcon 9 there were internal cameras to record staging events. Those video images were VERY cool. I have a question: What does an indestructible launch anomaly proof black box look like? AND.. can they float and phone home? Might those data recorders have other harsh environment uses? Say… on Venus or Mercury?

I know it is none of my business, but I’d like to know SpaceX’ thinking on all the rocket bodies that are completed, or nearly so. I’m guessing there is no handy access port to pop open to crawl into the tanks that have these struts to facilitate a mass-change out effort. So I see three options, 1) scrap all the completed and near-completed rocket bodies entirely. 2) Scrap the bodies for parts, but then somehow revalidate the recovered parts for reuse. 3) Build an improvised access into the tanks and replace the struts and somehow validate all those atypical processes. And I suppose a 4th option is to use them as-is for “low-value” missions; if there is any such thing. I fear they are the not-very happy owners of a lot of expensive, completed hardware that no one will want to use.

Guessing… until we know more. Meanwhile, ‘beef up’ the strut design?

I LOVE MIKE BROWN

http://i2.photobucket.com/albums/y33/HeadAroundU/i%20love%20mike%20brown.png

WE LOVE MIKE BROWN

http://i2.photobucket.com/albums/y33/HeadAroundU/i%20love%20mike%20brown.png

good link

http://i2.photobucket.com/albums/y33/HeadAroundU/we%20love%20mike%20brown.jpg

Hey Ken, look at my new positive art.