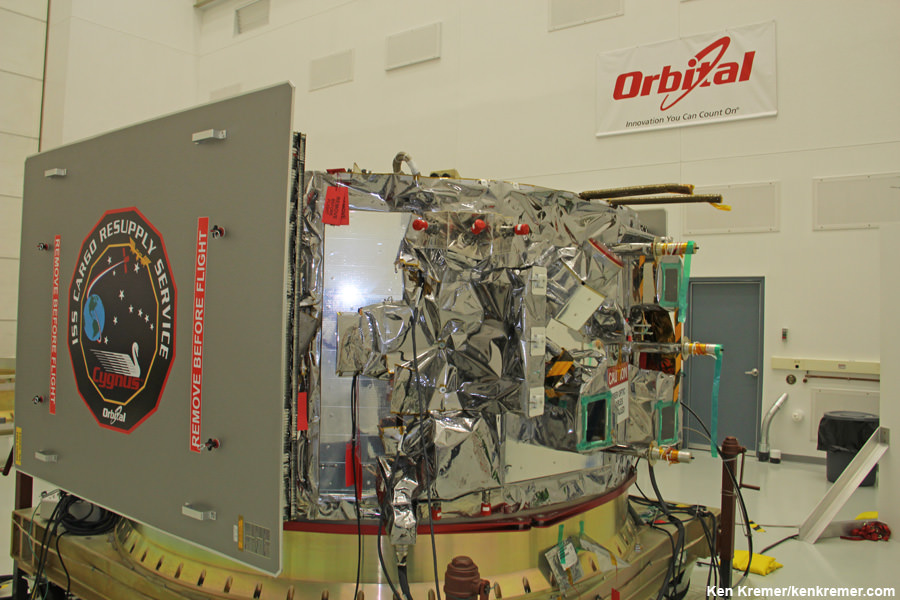

See OA-4 mission patch and hardware photos below

The biggest and heaviest Cygnus commercial cargo craft ever built by Orbital ATK is coming together at the Kennedy Space Center as the launch pace picks up steam for its critical ‘Return to Flight’ resupply mission to the space station for NASA. Cygnus is on target for an early December blastoff from Florida and the Orbital ATK team is “anxious to get flying again.”

“We are very excited about the upcoming [OA-4] cargo mission and returning to flight,” said Frank DeMauro, Orbital ATK Vice President for Human Spaceflight Systems Programs, in an exclusive interview with Universe Today.

The vehicle’s last major component, the service module, has just arrived at Kennedy for final prelaunch assembly.

“We have an obligation to our NASA customer and most importantly the crews aboard the International Space Station (ISS).”

The ‘Return to Flight’ mission, dubbed OA-4, fulfills Orbital ATK’s commitment to “meet our cargo requirements to NASA under the Commercial Resupply Services (CRS) contract” following the catastrophic launch failure of the firms Antares/Cygnus Orb-3 resupply mission to the space station moments after liftoff one year ago from Wallops Island, Virginia on October 28, 2014.

In order to get the Cygnus logistics spacecraft back into service for NASA as quick as possible, Orbital switched rockets and the vessel will be carried to orbit for the first time by a United Launch Alliance Atlas V rocket – now slated for liftoff on December 3, 2015 from Space Launch Complex 41 at Cape Canaveral Air Force Station in Florida at approximately 6 pm. ET.

“We are confident on the Dec. 3 launch date. And ULA is doing really well on the launch vehicle side,” DeMauro told me.

“The team has been chomping at the bit to get flying again. It’s been awhile.”

Indeed this enhanced Cygnus variant – flying for the first time in its longest configuration – is jam packed with the heaviest load ever heading to the space station, due to a combination of the loftier lift capabilities of ULA’s Atlas booster and the lengthier cargo module.

“We have a lot of cargo that we are planning to bring up!” DeMauro emphasized – “over 3500 kilograms.”

“We are taking advantage of the increased lift capability of the Atlas V. So with the enhanced Cygnus we are able to go from 2700 kg [with Antares] to 3500 kg of cargo [with Atlas V].”

This first flight of the longer, enhanced variant of the Cygnus spacecraft will deliver more than 7,700 pounds (3500 kilograms) of essential crew supplies, equipment and scientific experiments to astronauts on board the ISS.

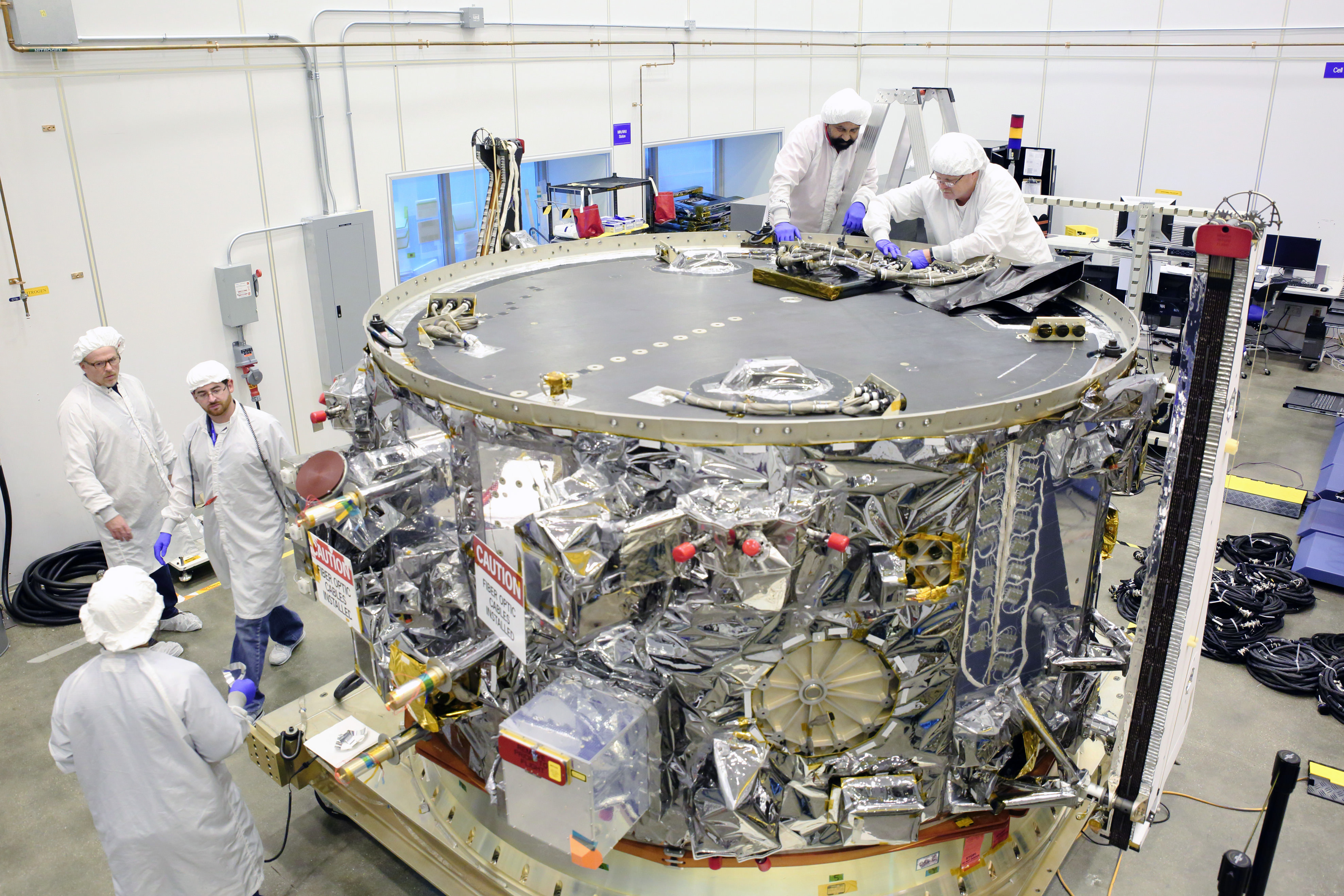

A key mission milestone leading up to launch was achieved on Wednesday, Oct. 14 with delivery of the Cygnus service module (SM) to Kennedy’s Space Station Processing Facility (SSPF).

The SM is the last major component of the Cygnus spacecraft required for launch and its now arrived on time for several weeks of integration work with the cargo carrying logistics module for pre-launch processing at the Florida space coast.

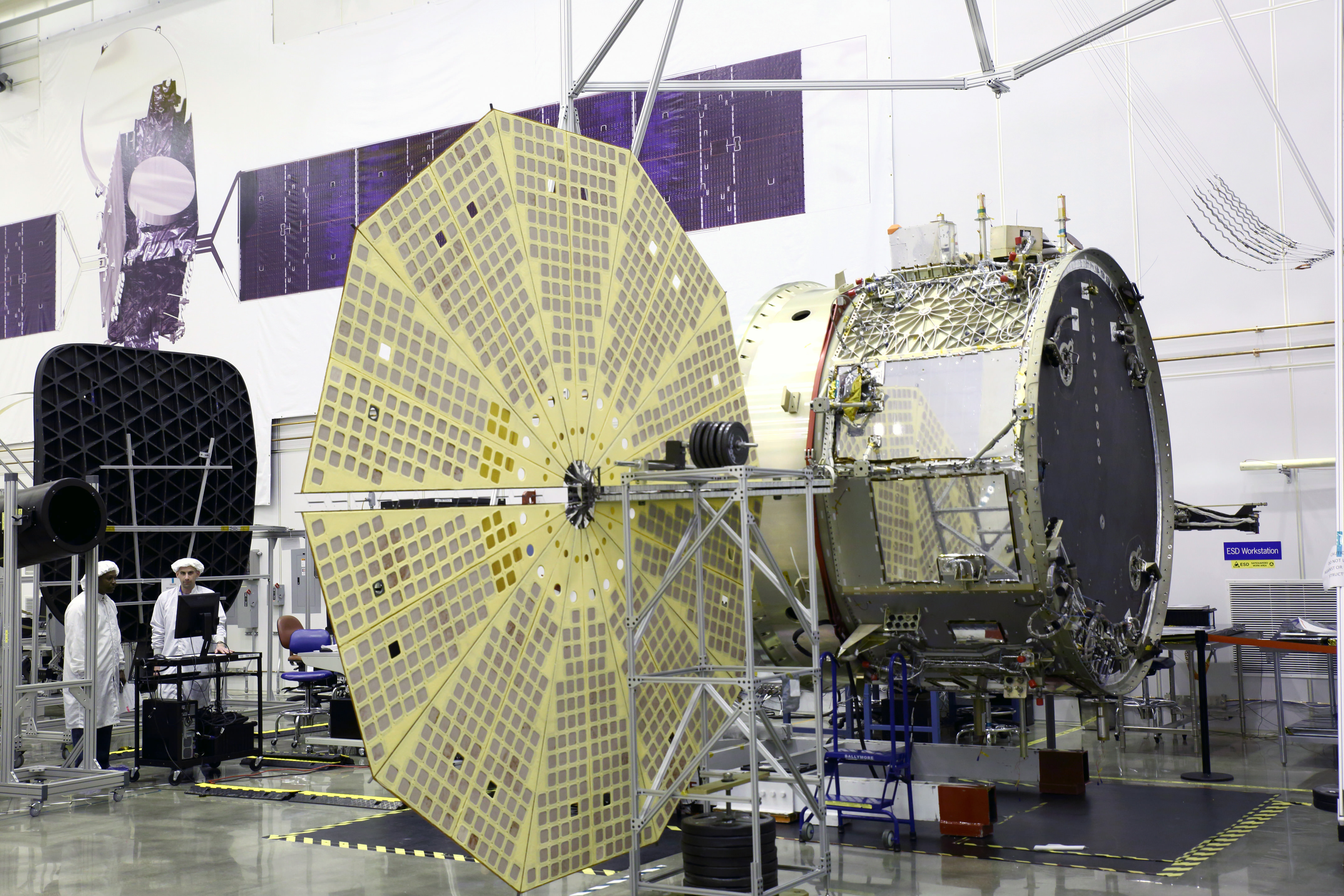

The Cygnus SM was manufactured at Orbital ATK’s Dulles, Virginia headquarters and provides the spacecraft’s avionics, propulsion and power systems. It propels the combined Cygnus vehicle to berth at the ISS.

The SM has also been upgraded with the lightweight UltraFlex solar panels flying for the first time on the OA-4 mission.

“These UltraFlex new solar arrays are being using as part of the design modifications introduced for the enhanced Cygnus. The plan was to reduce the mass of Cygnus to increase the cargo carrying capabilities of the entire spacecraft.”

The UltraFlex solar panels are 3.7 meters in diameter and approximately 25 kg lighter than those previously flown.

The next assembly step is to join the SM to the first ever extended variant of the Cygnus pressurized cargo module (PCM). The lengthened PCM enables delivery of the heaviest cargo load ever by Cygnus to the crews living and working aboard the orbital science complex.

“The enhanced Cygnus PCM is 1.2 meters longer, so it’s about 1/3 longer,” DeMauro told Universe Today.

“So you get that [heavier cargo load] by increasing the modules length and volume. And it’s based also on the packing scheme of the cargo.”

It can’t be emphasized enough that resupply flights are the essential lifeline to the station, without which it cannot exist. The cargo missions stock the station with all manner of equipment, science experiments, food, clothing spare parts and gear for the international crews of six astronauts and cosmonauts.

The October 2014 launch mishap was traced to a failure in the ‘Americanized’ and Russian-built NK-33 first stage engines of the firms Antares rocket, and ground flights to an immediate halt.

“Our response to the Antares failure was to figure out how to get the required cargo delivered to NASA in the timeframe that they needed,” DeMauro emphasized to Universe Today.

“So we went out and said, OK we have an obligation to our customer and the crews, most importantly, up on the ISS.”

“And so we thought hard and got to work immediately after we lost Orb-3 and came up with a plan to really utilize the existing Cygnus hardware.”

“We realized that Antares was going to need some time to get through their design work to accommodate the new RD-181 engine.”

“So we said we’ll partner with another launch vehicle provider to give Antares the time they need to get back flying. So we picked Atlas and we took advantage of the increased lift capability with the Atlas V.”

“So we went back to our cargo module provider [Thales Alenia] and asked “how can we fit more cargo inside.”

The Cygnus PCM is manufactured by Thales Alenia Space at their production facility in Turin, Italy under a subcontract from Orbital ATK.

“So we had a design and we had a plan – but we needed more!” DeMauro explained.

“So like a solid provider, they [Thales Alenia] came back with alternatives for ‘fitting more cargo in the same size module’ by making relatively low risk and modest changes to the internal secondary structure design of the cargo module.”

Therefore the Orbital team and their ULA and Italian partners responded to the Antares disaster in a creatively proactive manner to stuff the same Cygnus with an 30% additional cargo amounting to over 800 kilograms – in the same volume.

“So we are able to go from 2700 kg to 3500 kg. It’s been a lot of hard work but the team is anxious to get going again.”

And the astronaut and cosmonauts crews aboard the ISS are truly the top priority of this entire effort to keep NASA’s human spaceflight program alive and thriving.

“Our plan from the gitgo that we laid out in the concept of returning to flight – was get the cargo delivered to NASA that we were required to and do it in the time frame we were required to.”

“We are anxious to get flying again not only for our own sake, but really for NASA and the crew!” DeMauro told me.

Orbital ATK was awarded a $1.9 Billion supply contract by NASA to deliver 20,000 kilograms of research experiments, crew provisions, spare parts and hardware for 8 flights to the ISS through 2016 under the Commercial Resupply Services (CRS) initiative.

Three new flights have since been added by NASA, for a total of 10 Cygnus resupply missions through about 2018.

Orbital ATK’s commercial competitor, SpaceX, is likewise under contract with NASA to deliver 20,000 kg of supplies to the ISS with the SpaceX Falcon 9/Dragon architecture.

But SpaceX also suffered a launch failure this year in June 2015 following the CRS-7 ISS resupply liftoff from Cape Canaveral.

So NASA desperately needs both commercial cargo partners to safely resume station resupply launches.

I was an eyewitness to both calamities and plan to be onsite at the Kennedy Space Center press site for the OA-4 liftoff on Dec. 3.

ISS commander and NASA astronaut Scott Kelly and his comrades will surely welcome the Cygnus supplies in about 6 weeks time!

Stay tuned here for Ken’s continuing Earth and planetary science and human spaceflight news.