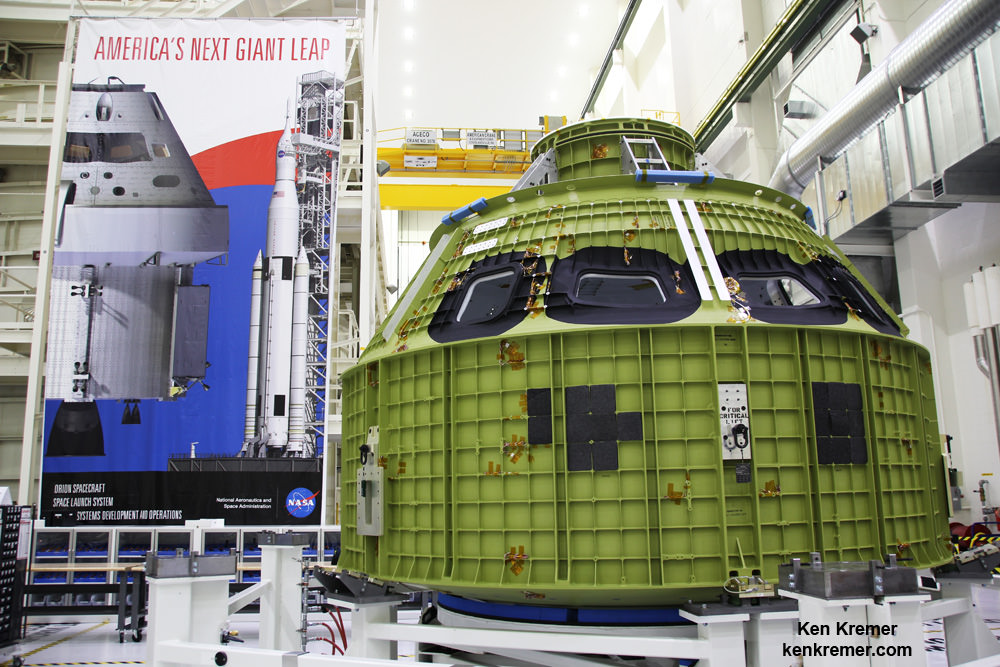

KENNEDY SPACE CENTER, FL – NASA officials proudly unveiled the pressure vessel for the agency’s new Orion capsule destined to launch on the EM-1 mission to the Moon in 2018, after the vehicle arrived at the Kennedy Space Center (KSC) in Florida last week aboard NASA’s unique Super Guppy aircraft.

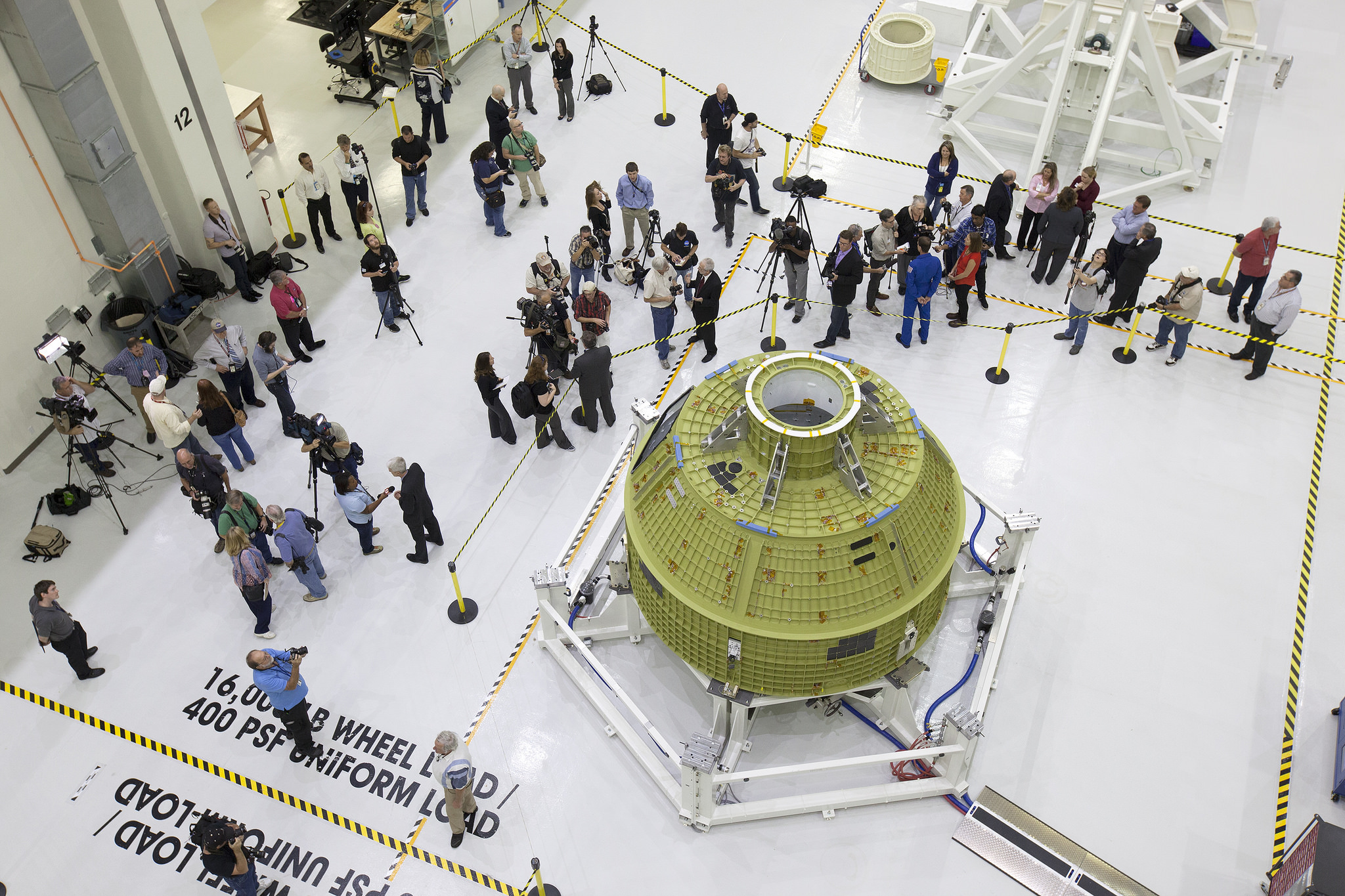

This ‘new and improved’ Orion was unloaded from the Super Guppy and moved to a test stand called the ‘birdcage’ in the high bay inside the Neil Armstrong Operations and Checkout (O&C) Building at KSC where it was showcased to the media including Universe Today.

Orion’s arrival at KSC truly signifies a major turning point in achieving NASA’s agency-wide goal of sending humans to the Red Planet in the 2030s to carry out the ‘Journey to Mars’ initiative.

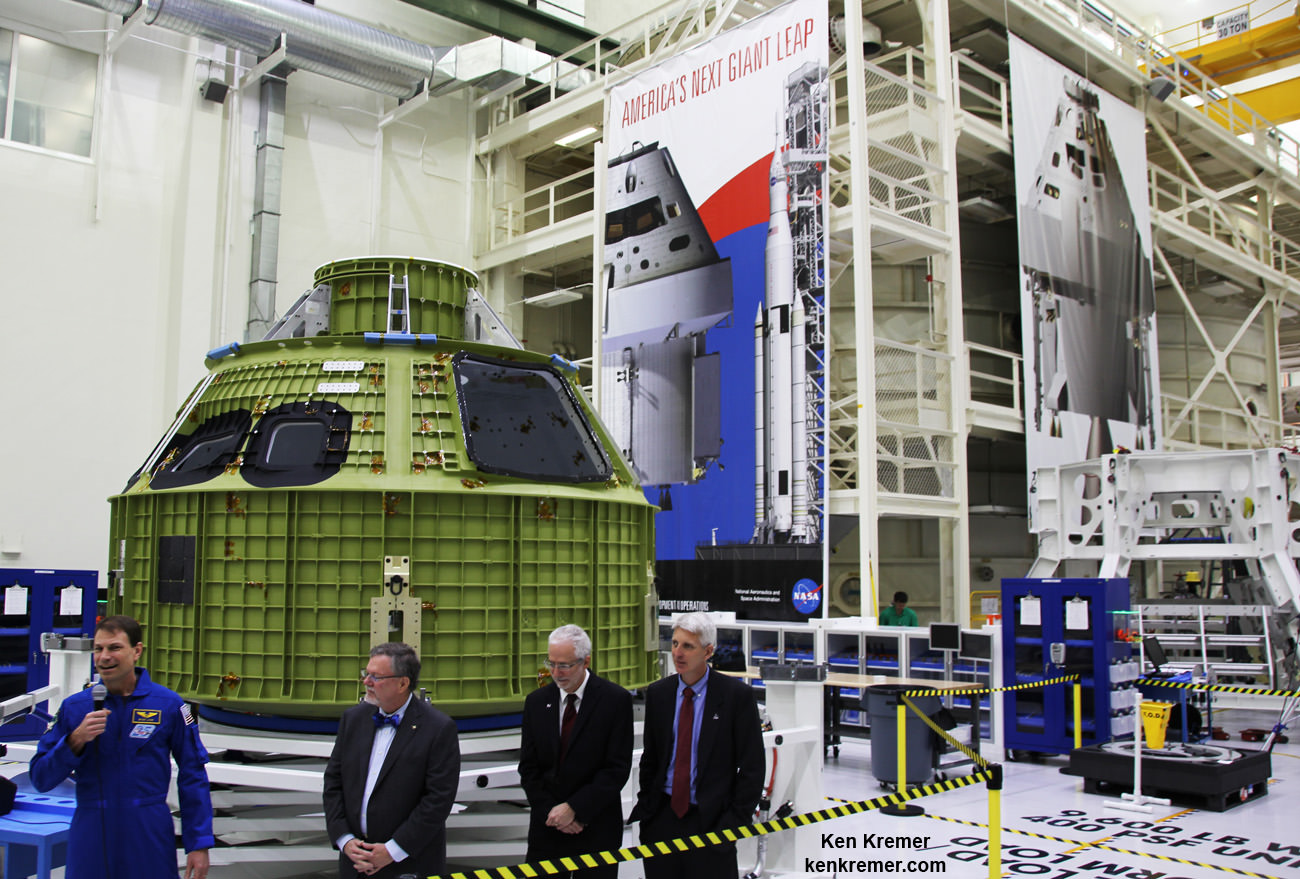

“This is an exciting day for NASA with the arrival of Orion,” NASA Orion program manager Scott Wilson told Universe Today.

“This is the first mission where the Orion spacecraft will be integrated with the large Space Launch System rocket. Orion is the vehicle that’s going to take astronauts to deep space.”

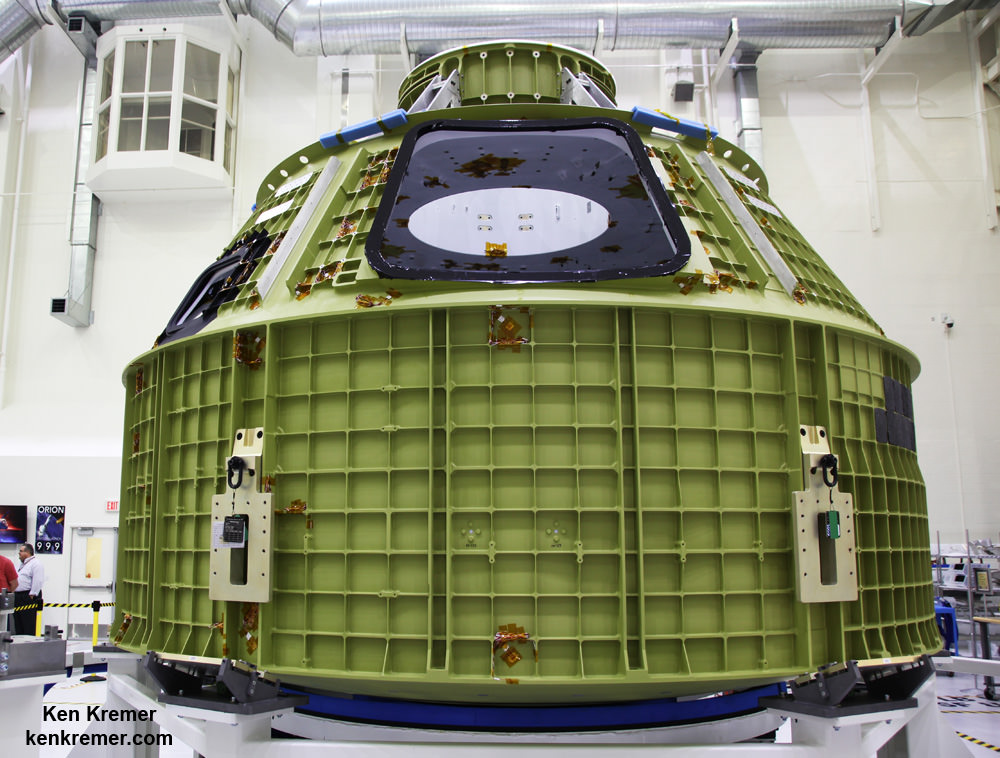

The Orion pressure vessel serves as the structural backbone for the spacecraft.

But before it can launch engineers and technicians from NASA and prime contractor Lockheed Martin will spend the next two years meticulously installing all the systems amounting to over 100,000 components and gear required for flight.

This particular ‘Lunar Orion’ crew module is intended for blastoff to the Moon in 2018 on NASA’s Exploration Mission-1 (EM-1) atop the agency’s mammoth new Space Launch System (SLS) rocket, simultaneously under development. The pressurized crew module serves as the living quarters for the astronauts comprising up to four crew members.

EM-1 itself is a ‘proving ground’ mission that will fly an unmanned Orion thousands of miles beyond the Moon, further than any human capable vehicle, and back to Earth, over the course of a three-week mission.

NASA is planning the first manned flight in about three years later in 2021, depend on the budget allocation.

“We are targeting the first crewed flight for around 2021 on Exploration Mission-2 (EM-2),” Mark Geyer,, deputy director of NASA’s Johnson Space Center in Houston, told Universe Today in an interview beside the Orion EM-1 pressure vessel.

“Achieving the 2021 launch date depends on received a sufficient budget to achieve the mission milestones and timelines.”

The olive green colored pressure vessel is the spacecraft’s underlying structure on which all of the spacecraft’s systems and subsystems are built and integrated prior to liftoff for its inaugural flight to the Moon and back.

The pressure vessel was manufactured at NASA’s Michoud Assembly Facility in New Orleans, where it was welded into shape by NASA and Lockheed Martin engineers using an advanced friction-stir welding process.

The EM-1 pressure vessel weighs about 2700 lbs. It stands 10 feet high and is nearly 5 meters in diameter. After installing the thermal protection system, the finished Orion flight capsule will be about 11 feet high and 16.5 feet wide.

These systems include the heat shield, thermal protection, propulsion, avionics, computers, plumbing, electrical, life support, parachutes and much more.

“We plan to power on this Orion one year from now,” Mike Hawes, Lockheed Martin Orion vice president and program manager, told Universe Today in a interview beside the Orion EM-1.

Technicians will then continue adding components and test the vehicle along the way.

Lockheed is achieving the point of power on in a shorter timeframe compared to the prior Orion EFT-1 spacecraft because of the many lessons learned, Hawes told me.

The team “learned how to shed weight, reduce costs and simplify the manufacturing process – all in an effort to improve the production time and cost of future Orions,” said Lockheed officials.

The pressure vessel itself is comprised of seven large aluminum pieces that Michoud technicians began welding together in September 2015 using the highly precise state-of-the-art process called friction-stir welding.

The last of the seven friction-stir welds to assemble the primary structure for NASA’s EM-1 capsule was finished on Jan. 13.

“The structure shown here is 500 pounds lighter than its Exploration Flight Test-1 (EFT-1) counterpart,” said Hawes. “Once the final structural components such as longerons, bolts and brackets are added, total crew module structural weight savings from EFT-1 to EM-1 will total 700 pounds.”

“Some of the weight saving is due to use of a thinner shell and some to the need of fewer welds,” Hawes told me.

Among the advances since EFT-1 are that engineers have reduced the number of welds from 33 to 7. This vastly reduced welding requirement saved time, money and weight which can be directly converted into up mass to carry out the exploration mission.

Overall this is the third Orion capsule that NASA has built, following the Ground Test Article (GTA), which did not fly, and the EFT-1 capsule which successfully launched just over one year ago on Dec. 5, 2014.

“Our very talented team in Louisiana has manufactured a great product and now they have passed the baton to Florida,” said Hawes. “This is where we assemble, test and launch, and the fun really begins.”

Along with all the vehicle manufacturing at KSC, “the crew module will undergo several tests to ensure the structure is perfectly sound before being integrated with other elements of the spacecraft. First it will undergo proof-pressure testing where the structural welds are stress tested to confirm it can withstand the environments it will experience in space. The team will then use phased array technology to inspect the welds to make sure there are no defects. Additional structural tests will follow including proof-pressure testing of the fluid system welds and subsequent x-ray inspections,” say NASA officials.

“Once the crew module passes those tests it will undergo final assembly, integration and entire vehicle testing in order to prepare for EM-1.”

The 2018 launch of NASA’s Orion on the unpiloted flight dubbed Exploration Mission, or EM-1, counts as the first joint flight of SLS and Orion, and the first flight of a human rated spacecraft to deep space since the Apollo Moon landing era ended more than 4 decades ago.

Orion is designed to send astronauts deeper into space than ever before, including missions to the Moon, asteroids and the Red Planet.

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news.

There would have to be a bit more going to Mars than just this capsule and a lander. A lot more space for people and consumables please!

Hematite – I am guessing when they say go to Mars they just mean sending this capsule (or one like it) into Mars orbit to test out the rocket infrastructure for a later mission which would presumably include a (much larger and more sophisticated) lander which could land (retro-propulsively) and return to an orbiter (propulsively) (definitely no chance of this capsule landing and returning to Mars orbit as is)…