The Moon is not just Earth's closest celestial neighbor. It's also a natural waypoint for any mission that will be going to Mars or beyond in the coming years. It's little wonder then why space agencies like NASA, Roscosmos, the ESA and China are hoping to send crewed missions there in the near future and construct bases that could be used to resupply and refuel missions headed to deep space.

So far, all the proposals made for a lunar base have centered on in-situ resource utilization (ISRU) and 3D printing - where robots will manufacture the base out of lunar regolith. For this purpose, the Laser Zentrum Hannover (LZH) and the Institute of Space Systems (IRAS) at the Technical University of Braunschweig came together to develop a laser system capable of turning moon dust into building materials.

The ability to generate building materials using local resources is an absolute must for the future of space exploration. At present, the cost of launching payloads to the Moon is still prohibitively expensive - estimated at roughly $780,000 a kilogram ($355,000 a pound). For this reason, the most cost-effective plans involve manufacturing everything directly on the lunar surface.

Enter the MOONRISE project, which aims to marry laser technology with a rover design. As Niklas Gerdes, a research assistant from theLZH,explained in a LZH press release:

As atechnology-demonstrator, the purpose of MOONRISE is to validate the lightweight laser system designed by the IRAS/LZH science team, which weighs no more than 3 kg (6.6 lbs). Specifically, the team wants to prove that it has the volume of a larger laser and can melt lunar regolith and convert it into useable and versatile building materials.

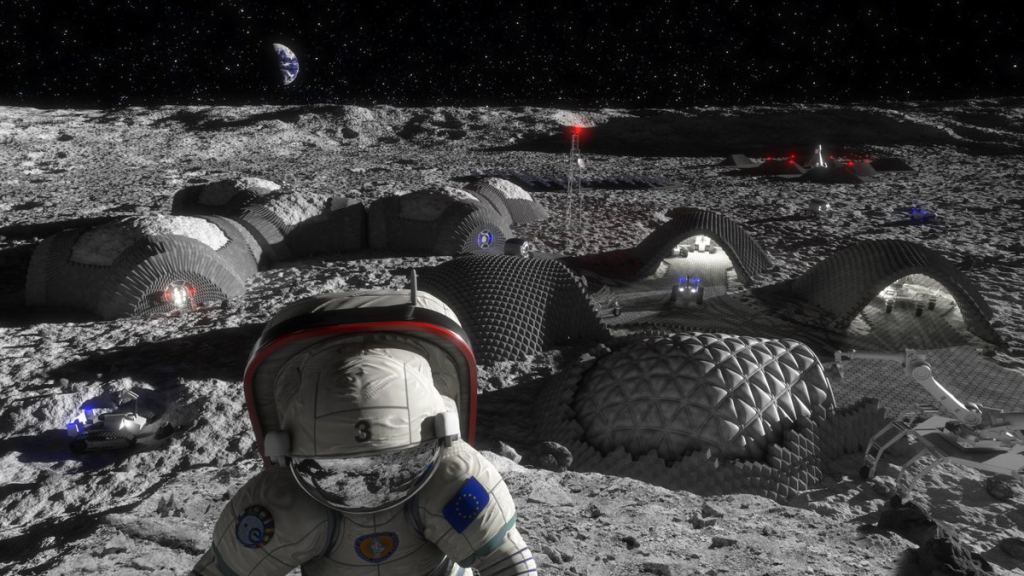

Like various 3D printing concepts that are being explored, the idea here is to turn lunar regolith into a molten ceramic. This viscous liquid is then printed out and freezes on contact with the frigid lunar environment to form the foundations, walls, and interiors of structures. This method is one possible way the ESA is planning on building its proposed International Moon Village, a lunar base that would act as a spiritual successor to the ISS.

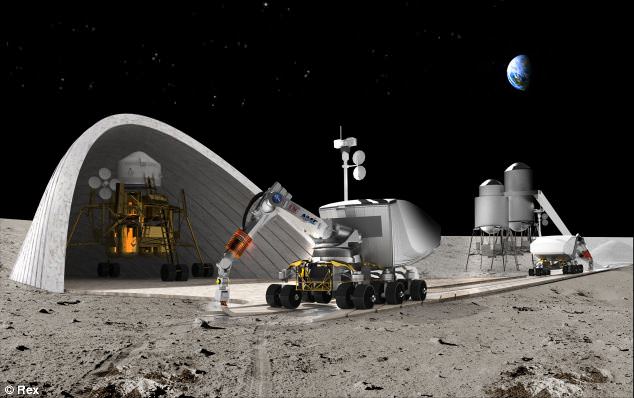

The plan is to launch the MOONRISE aboard an inaugural flight provided by PTScientists, a Berlin-based NewSpace company dedicated to providing affordable access to the Moon. For the sake of the mission, the MOONRISE will be delivered to the Moon via a proprietary vehicle - an Autonomous Landing and Navigation Module (ALINA) and four-wheeled lunar rover - Audi lunar quattro.

Once there, MOONRISE will use its laser to melt regolith into predefined structures (a process which will be recorded using high-resolution cameras). Should the lunar experiment prove to be successful, the research team expects that the technology will be scaled up to produce entire lunar infrastructures - such as foundations, paths, and landing surfaces.

This will represent the culmination of tests that have been taking place for nine months with funding provided by the Volkswagen Foundation, which is dedicated to supporting cutting-edge research. As IRAS Prof. Enrico Stoll explained, it will also be the culmination of years of hard work and lucrative collaboration.

"IRAS and LZH have been working together on the underlying process for the MOONRISE technology since 2015," he said. "Now, through the project, we have the opportunity to show Additive Manufacturing outside of the Earth and of the Earth's orbit for the first time in history."

The results of the previous tests are promising, which validated the system's laser hardware and optics. The science team has also been using materials that are increasingly similar to lunar regolith to see if the laser is capable of melting them. Currently, the team is working on integrating the laser to fit into the load compartment of the lunar rover so that it is able to fire out of the underside.

After the integration process is complete, the entire system will be tested to see if it can survive the trip through space - where it will be subject to the physical shocks associated with launches and massive differences in temperatures. Other tests involve how the laser will perform in a lower gravity environment. Said Prof. Ludger Overmeyer, the Chairman of the LZH's Scientific Directorate:

"The planned direct proof, that we are able to process lunar regolith with already available hardware components is crucial for the planning of future missions," said Stefan Linke, an engineer with the IRAS. "Thus, larger and more sustainable projects on the surface of our cosmic neighbor are becoming possible. "

Regardless of the outcome of the lunar tests, the project is sure to provide valued scientific and technical data concerning the viability of 3D printing on the Moon. In the end, these and other tests will help inform all future efforts to build the International Moon Village and any other lunar outposts that are built in the coming decades.

*Further Reading: LZH*

Universe Today

Universe Today