One of the chief aims of space agencies and commercial aerospace these days is reducing the associated costs of space exploration. When it comes right down to it, it is still very expensive to send rockets into orbit, never mind sending them beyond Earth. But it's not just the cost of sending payloads into space (and the pollution it causes) that concerns agencies like NASA.

There is also the cost (economic as well as environmental) associated with aviation. Jet fuel is not cheap either, and commercial air travel accounts for 4 to 9% of anthropogenic greenhouse gases (and is on the rise). For this reason, NASA has partnered with the commercial industry to develop electric aircraft, which they hope will provide a fuel- and- cost-efficient alternative to commercial jets by 2035.

This represents a significant challenge since many of the components needed to create a functioning electric aircraft are rather large and heavy. In particular, NASA's Advanced Air Vehicles Program (AAVP) is looking for lightweight and compact inverters - a central component of an electric system that provides power to drive the electric motor.

Inverters are critical to electronic propulsion systems since they convert alternating current (AC) - generated by engine-mounted generators and the electric motors driven by propellers - to the high-voltage direct current (DC) power. Unfortunately, the components needed to generate that amount of power - generators, power conversion electronics, motors, etc. - have historically been far too large and heavy to fit in an aircraft.

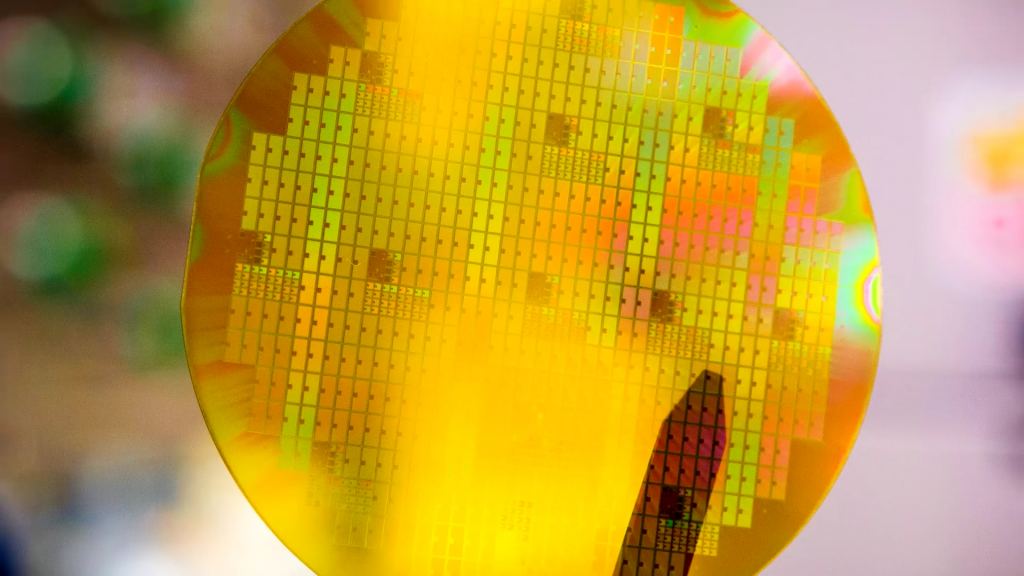

This creates something of a conundrum since the amount of energy needed to generate the necessary lift would require even heavier electronics. Hence why NASA is investigating cutting-edge material science to create lighter and smaller electronics. To this end, they recently signed a $12 million contract with General Electric (GE), one of the world leaders in the development of cutting-edge silicon carbide (SiC) technology.

This semiconducting mineral is used in the fabrication of high-temperature, high-voltage electronics, and GE is hoping to use it to meet the size, power, and efficiency requirements specified by NASA. These specifications call for an inverter that is no larger than a suitcase and capable of generating a megawatt (MWs) of electricity.

As Jim Heidmann, manager of NASA's Advanced Air Transport Technology Project, explained in a NASA press release:

Put simply, a megawatt is a tremendous amount of electricity and managing that kind of power safely is a major challenge. For example, NASA's Single-aisle Turboelectric Aircraft with an Aft Boundary-Layer (STARC-ABL) - which utilizes advanced propulsion technologies to decrease fuel usage, emissions, and noise - requires 2.4 MW of power to operate, which is enough electricity to run 2,000 homes.

But thanks to strides made in the field of electronics and hybrid engine technology in recent years, these requirements could be within reach. Said Amy Jankovsky, manager of the Hybrid Gas-Electric Propulsion subproject at NASA's Glenn Research Center:

Silicon carbide is especially promising for high-power aviation applications because of its material properties. It offers high operating temperatures, high-voltage, and a high power handling capacity. These advantages will allow engineers the ability to design components that are smaller in size and lighter while also increasing the power output.

"We're essentially packing one megawatt of power into the size of a compact suitcase that will convert enough electric power to enable hybrid-electric propulsion architectures for commercial airplanes," said Konrad Weeber, chief engineer of Electric Power at GE Research. "We have successfully built and demonstrated inverters at ground level that meet the power, size and efficiency requirements of electric flight."

The development of these electric systems in currently taking place at NASA Electric Aircraft Testbed (NEAT) in Sandusky, Ohio, which was previously the NASA Glenn Hypersonic Tunnel Facility. The first of its kind, this reconfigurable testbed is charged with designing, developing, assembling and testing the electric aircraft power systems that will go into the creation of everything from two-person aircraft to 20 MW airliners.

Back in May, NEAT was able to conduct its first megawatt-scale test thanks to the massive amounts of power the facility has access to. This and the recently-signed partnership with GE comes just shortly after NASA announced another lucrative partnership with GE and two major aerospace companies - Boeing and United Technologies Pratt & Whitney - to study the possible benefits and risks of megawatt-scale flight demonstrations.

As Barb Esker, the deputy director of NASA's Advanced Air Vehicles Program, put it:

Between the threat of climate change and the fact that the world's population is projected to reach close to 10 billion by 2050, it is clear that alternative means of manufacturing, energy production, and transportation need to be developed. It's good to know that alongside electric and hybrid cars, we can look forward to electric and hybrid planes.

*Further Reading: NASA*

Universe Today

Universe Today