The Moon has abundant oxygen and minerals, things that are indispensable to any space-faring civilization. The problem is they're locked up together in the regolith. Separating the two will provide a wealth of critical resources, but separating them is a knotty problem.

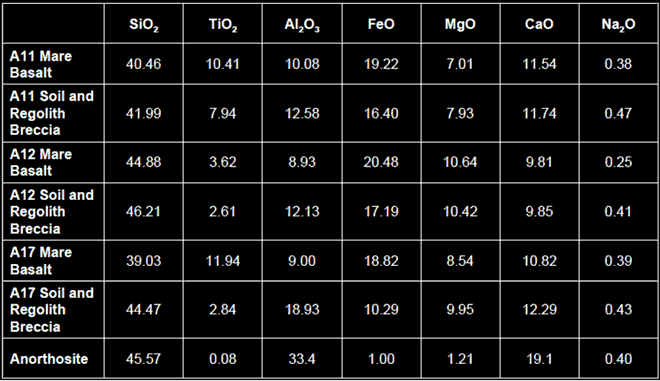

The Moon's regolith varies from 2 meters (6.5 ft.) deep in mare regions, to 20 meters (65 ft.) deep in highland regions. Unlike Earth, where the surface is shaped and built by both biological and geological processes, the Moon's regolith is largely made up of pulverized, blasted fragments of the crust caused by impacts. The oxygen and minerals are locked up in mineral oxides, and in glassy particles created through the heat of impacts.

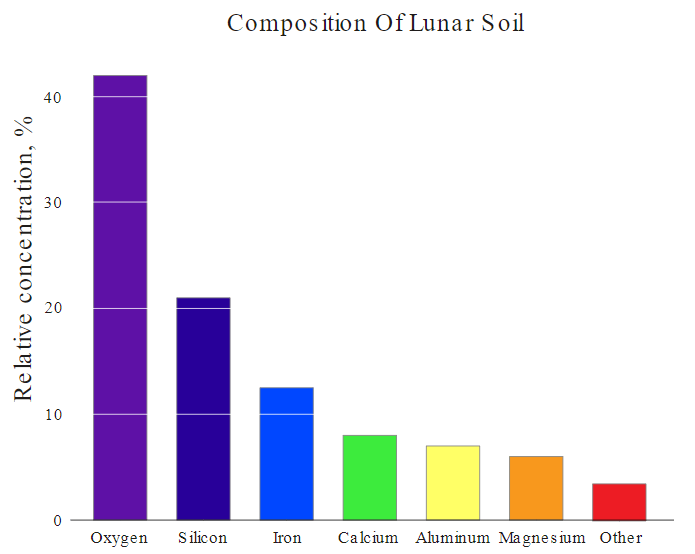

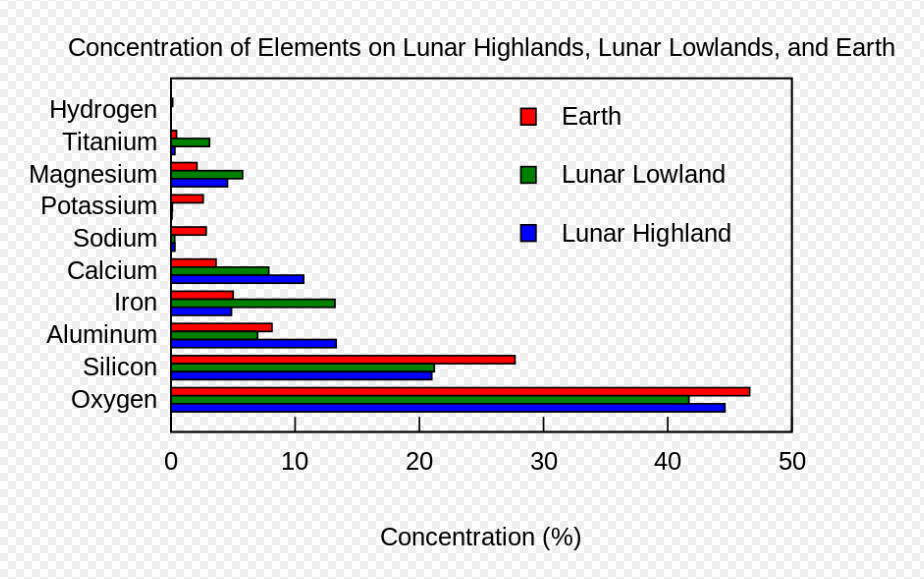

Oxygen is the most abundant element in the Moon's regolith, making up between 40-45% of the regolith by weight. Scientists have been studying In Situ Resource Utilization (ISRU) for years, trying to find a method of separating the oxygen from the other elements, to make use of both. Typically, that requires a lot of energy, which is a significant barrier.

New research supported by the European Space Agency outlines a method for oxygen extraction that doesn't require so much energy.

"This oxygen is an extremely valuable resource, but it is chemically bound in the material as oxides in the form of minerals or glass, and is therefore unavailable for immediate use," explains researcher Beth Lomax of the University of Glasgow, whose PhD work is being supported through ESA's Networking and Partnering Initiative, harnessing advanced academic research for space applications.

"This research provides a proof-of-concept that we can extract and utilise all the oxygen from lunar regolith, leaving a potentially useful metallic by-product," Lomax said in a press release.

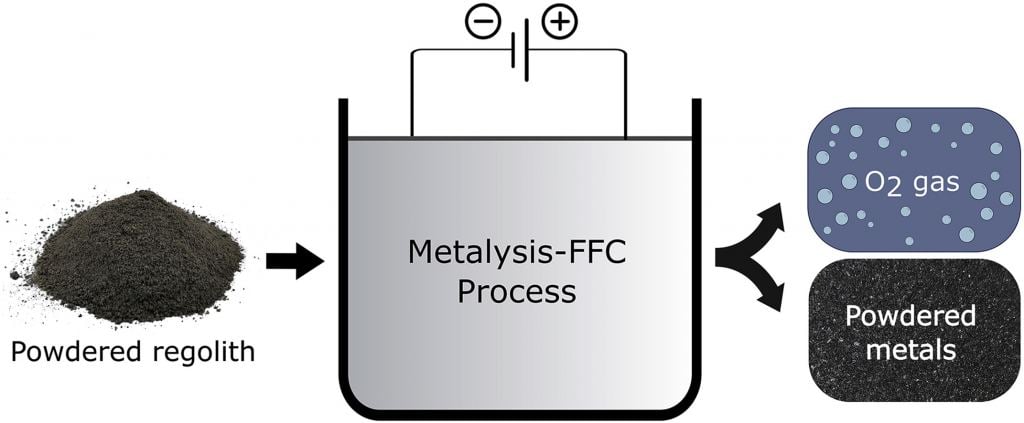

The extraction method relies on electrolysis, something most of us learn about in high school. But this method uses molten salt as an electrolyte.

"The processing was performed using a method called molten salt electrolysis," said Lomax. "This is the first example of direct powder-to-powder processing of solid lunar regolith simulant that can extract virtually all the oxygen. Alternative methods of lunar oxygen extraction achieve significantly lower yields, or require the regolith to be melted with extreme temperatures of more than 1600°C."

This method uses molten calcium chloride salt as an electrolyte. The simulated regolith is placed in a mesh basket and it's all heated to 950 C (1740 F.) At that temperature the regolith remains solid. Then current is applied, and the oxygen is extracted and collected at an anode. Other methods of extraction require heating everything to 1600 C (2900 F), a massive increase in energy required.

This method extracted 96% of the oxygen in 50 hours. But in only 15 hours, it was able to extract 75%. Since oxygen is so abundant in the lunar regolith, these results look promising.

"This work is based on the FCC process – from the initials of its Cambridge-based inventors – which has been scaled up by a UK company called Metalysis for commercial metal and alloy production," Lomax said.

Metalysis developed the molten salt electrolysis method precisely because it's less energy intensive. The material to be separated doesn't need to be liquid, so less energy is required. They also claim their system doesn't produce any toxic by-products.

"We are working with Metalysis and ESA to translate this industrial process to the lunar context, and the results so far are very promising," notes Mark Symes, Beth's PhD supervisor at the University of Glasgow.

The availability of different minerals changes depending on location on the Moon. There's a lot of work going into mapping and exploring the Moon's resources.

James Carpenter, ESA's lunar strategy officer comments: "This process would give lunar settlers access to oxygen for fuel and life support, as well as a wide range of metal alloys for in-situ manufacturing – the exact feedstock available would depend on where on the Moon they land."

With reusable rockets developed by companies like SpaceX, the cost of transporting material out of Earth's gravity well has dropped. But it's still expensive. It can costs tens of thousands of dollars to transport a single kilogram to the Moon. That cost means that any realistic plans for a Moon outpost or colony would be a huge drain financially.

Without a way to extract resources for fuel and construction, and without a source of oxygen on the Moon, it seems unlikely that humans can establish any kind of presence there. Technology advances like this will play a huge role in the future of space exploration.

More:

- Press Release: OXYGEN AND METAL FROM LUNAR REGOLITH

- Research Paper: Proving the viability of an electrochemical process for the simultaneous extraction of oxygen and production of metal alloys from lunar regolith

- NASA: In Situ Resource Utilization

- Universe Today:

Universe Today

Universe Today