When it comes to telescopes, bigger is better. That’s true down here on Earth, and it’s especially true out in space. As astronomers and engineers design the next generation of giant space telescopes, they’re running up against the limits of current launch providers. There are only so many ways you can fold a huge telescope to get it to fit inside a 5-meter launch fairing.

The upcoming James Webb Space Telescope is pretty much the very limit of what you can construct on Earth and put into space in a single launch. To go bigger, space agencies will need to consider assembling their next-generation space telescopes… in space.

When the Hubble Space Telescope was launched in 1990, it was carried to space onboard the Space Shuttle Discovery. Many of the capabilities of the telescope, including its 2.4-meter mirror, were designed around what would fit inside the shuttle’s cargo bay.

The largest telescope aperture ever launched into space was the European Space Agency’s Herschel infrared observatory and its 3.5-meter primary mirror. With all its instruments and wrap-around solar panels, Herschel just barely fit inside the 4.6-meter launch fairing of its Ariane 5 ECA launch vehicle.

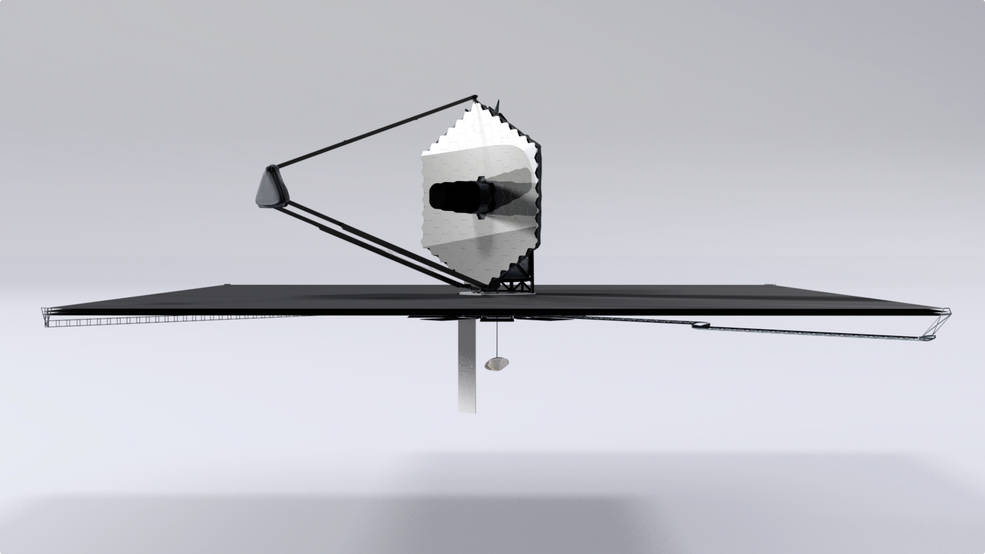

As engineers designed the next-generation James Webb Space Telescope, with its 6.5-meter mirror and tennis court-sized sunshield, they needed to embrace the art of origami to get the entire telescope to fit inside a single Ariane 5 rocket.

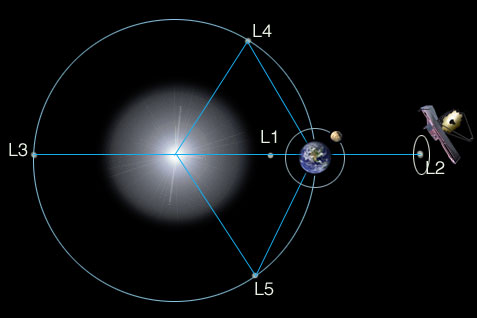

When James Webb deploys from its launch fairing and unfurls itself at its final Sun-Earth L2 Lagrange Point home, it will undergo an enormously complicated transformation.

The telescope will undergo 20 deployment events, each of which has to go perfectly, one after the other. 40 different structures, including its sunshield and main mirror, will need to be deployed. There are 178 separate release mechanisms which need to work perfectly.

There’s no do-over. And if anything happens during this deployment, there’s no way to fix it.

We’re nearing the time of the next Decadal Survey, where astronomers, astrophysicists, and engineers come together to work out their wishlist of future science goals. What are the biggest outstanding questions in astronomy, and what are the instruments, experiments, and observatories that’ll best help provide answers?

Whatever they decide, the next generation will bring larger telescopes. Whether it’s a full spectrum observatory like LUVOIR, which can follow in the footsteps of Hubble with a vastly larger main mirror, a habitable exoplanet-hunting specialist like HabEx or an advanced X-Ray observatory like Lynx, these things are going to be big.

No amount of origami will make them fit inside a 5-meter fairing. They won’t even fit easily inside a SpaceX Starship.

Maybe this next generation of space telescopes will be assembled… in space.

As Hubble nears the end of its life, and we prepare for the launch of James Webb and WFIRST, scientists and engineers are considering space-based construction methods for the telescopes that come after.

In May 2018, NASA chartered a study in the construction of space telescopes while they’re in space: the technique is called “In-Space Assembly”.

They asked themselves the question, “Since telescopes are getting bigger and bigger, eventually too big to fit inside a launch fairing, when will it be worth assembling space telescopes in space rather than building them on Earth and deploying them autonomously from single launch vehicles”?

Their study involved dozens of participants from NASA centers, private companies, government agencies, and universities, with expertise in rendezvous and proximity operations, robotics, telescope optics, structures, instruments, launch vehicles, and orbital dynamics.

The basics of in-space assembly have been developed over decades with various missions during the Gemini and Apollo Eras as well as Soviet missions like Mir.

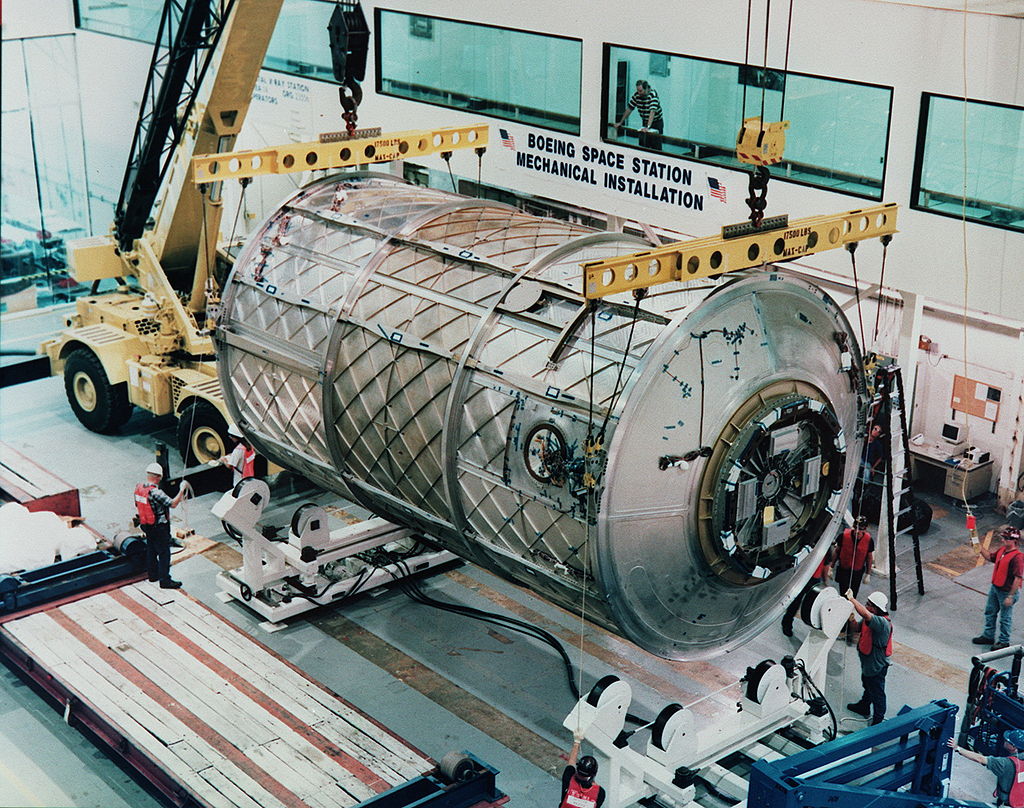

But the best example, of course, is the International Space Station, which was assembled piece by piece over the course of more than 30 separate missions. The first piece launched was the Russian Zarya Module, which was attached to the US Unity Module. Over the next two decades, many more space shuttles, as well as cargo launches from the United States, Russia, Europe, and Japan continued to add modules to the station.

Astronauts worked in tandem with various remotely-operated robotic arms to attach the modules together to the huge space station we see today.

Although construction has been successful, it wasn’t always smooth. Modules were delayed, technical problems needed to be overcome. Aging hardware was swapped out for more modern versions.

Another compelling example is the Hubble Space Telescope, which is a much better telescope today than it was when it was first launched. Over the decades, astronauts refueled, repaired and upgraded its science instruments with more advanced counterparts.

Although ISS and Hubble were worked on by humans, robots play a big role in the ongoing maintenance of ISS. SpaceX Dragon capsules carrying supplies automatically dock with the station’s Canadarm2 robotic arm. The arm then moves the capsule to an open berthing port on the station.

In order to answer the question, when does in-space assembly make sense, the team designed an example mega space telescope, and then compared how that mission might have gone with space-based assembly, and compared it to the traditional method of telescope construction on the ground.

This telescope sounds pretty sweet.

Unlike James Webb, this would be a follow-on mission to Hubble capable of seeing a wide array of wavelengths from infrared, through visible and into the ultraviolet. They considered telescopes as small as 5 meters – twice the diameter of Hubble – and up to 20 meters, which would be too large for any existing launch vehicle.

This mission would be sent to the Sun-Earth L2 Lagrange point, and have the capability of observing exoplanets, using a coronograph to block the light from their stars.

They assumed that each component would need to fit within a 5-meter class launch vehicle fairing, like a Falcon Heavy, Ariane 6, or United Launch Alliance Vulcan rocket.

I’m going to talk about the biggest version here, because, of course, I am.

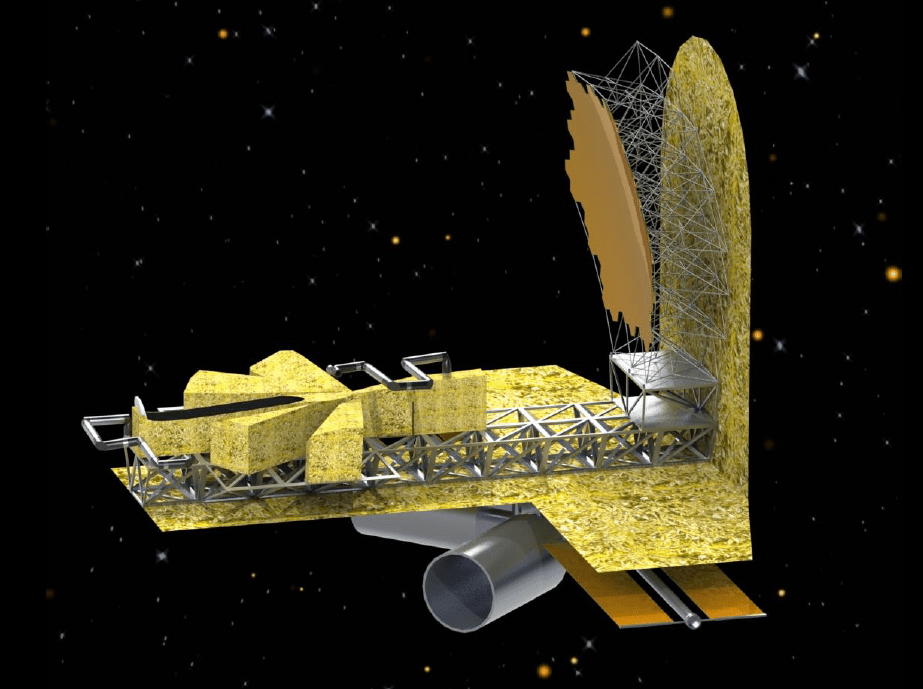

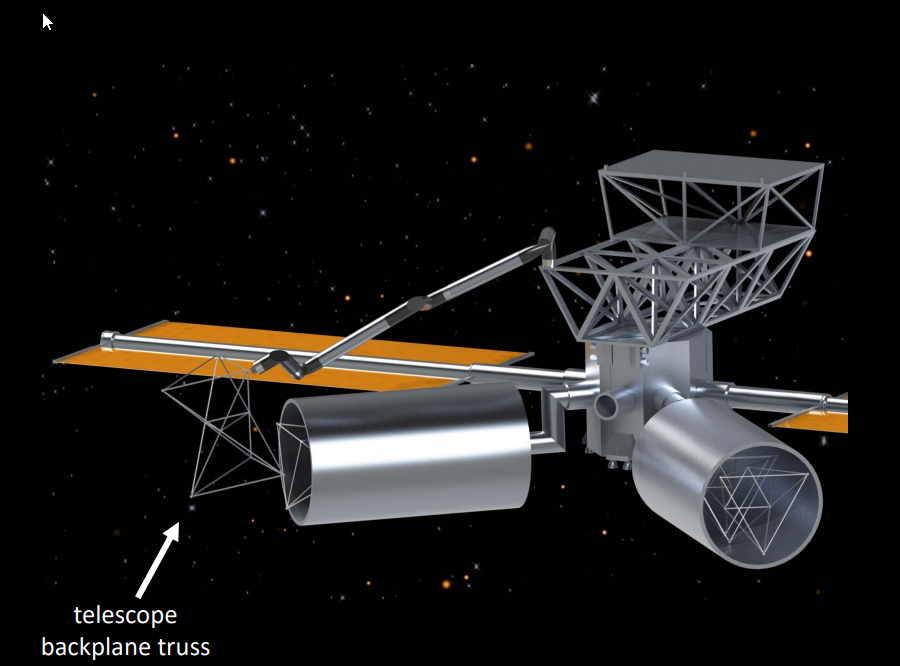

Their final design was an off-axis 20-meter telescope made up of several major components like structural trusses, telescope mirror segments, solar panels, sunshades, and modules containing instruments and other electronics.

The first launch would be the spacecraft bus, which would contain most of its electronics, power generation, as well as multiple robotic arms. It would be launched into an assembly orbit that would allow it to shift to the Sun-Earth L2 Lagrange point with very little propellant once assembly was complete.

Then additional modules would be launched into the same orbit and captured by the spacecraft bus. It would use its arm to assemble the telescope piece by piece, building the backplane, deploying the sunshade, assembling the primary mirror from smaller hexagonal pieces, aligning the secondary mirror, and installing the various science instruments.

Once it was fully assembled, the telescope would be shifted to its new L2 position where it would begin delivering data from a 20-meter space telescope.

As I mentioned earlier in the video, the purpose of the study was to figure out when in-space construction of space telescopes is the right path to take, and their conclusion was: now is fine.

Although there a few technological challenges that still need to be overcome, much of the work has already been done. The Hubble servicing missions showed that a space-based telescope can be repaired and upgraded. Even parts that were never intended to be serviced in space were successfully worked on.

The construction of the International Space Station showed that a spacecraft’s individual components can be built down on Earth and then assembled in space.

Although most of the work was done by human astronauts and cosmonauts, the precision automated docking by cargo spacecraft and use of the robotic arms shows what’s now routine.

By breaking up the telescope into smaller pieces, NASA might actually be able to save costs on many elements. In order to make James Webb fit into its launch fairing, engineers had to build complicated multi-staged release mechanisms out of the lightest possible materials. And if you’ve ever bought lightweight hiking gear, you know it gets expensive quick.

In a super-heavy launch vehicle, the largest possible foldest space telescope is about 15-meters across. With a space-assembled telescope, there’s no practical limit.

Since the telescope is assembled in space, it should be relatively straightforward to continue servicing it, swapping out instruments when new technology is developed, or fixing failed reaction wheels. If the telescope runs out of fuel for station-keeping, just send up a tanker to refuel it and enjoy another few decades of service. Once the robotic arm completes the construction of the telescope, it can just go into hibernation, waiting for a new mission to repair, upgrade, refuel or service the spacecraft.

Rockets still fail from time to time, and if one does, you don’t lose your entire telescope. A replacement part can be built and launched with a quicker timeframe.

According to the researchers, there aren’t any showstoppers to start assembling telescopes in space. They were relieved to find that it doesn’t violate the laws of physics. Phew.

Overall they found that space-assembled telescopes are competitive in costs with single-launch observatories. And for the biggest telescopes, there are no other options.

They’re not completely ready to fly, however, NASA still needs to develop modular elements as well as in-space verification and validation.

In the end, they concluded that even telescopes as small as 5-meters may benefit from in-space assembly. And when you consider future servicing missions, the benefits are even more important.

When James Webb finally lifts off, it could mark the end of an era. The last time that a giant telescope was built on the ground and then sent to space in a single launch.

Future telescopes could be built in pieces and then assembled in space, getting bigger and better over time as the technology advances.

This isn’t a question of if, it’s a matter of when.

Source: NASA iSAT Study

It’ll be a lovely thing to watch as telescopes in space get more and more capability.

Out of curiosity, how much larger is the fairing going to be on a BFR?