It has been suggested that if humanity wants to truly embark on a renewed era of space exploration, one of the key ingredients is the ability to manufacture structures in space. By assembling everything from satellites to spacecraft in orbit, we would eliminate the most costly aspect of going to space. This, simply put, is the sheer expense of escaping Earth's gravity well, which requires heavy launch vehicles and LOTS of fuel!

This is the idea behind the Space Infrastructure Dexterous Robot (SPIDER), a technology-demonstrator that will be going to space as part of NASA's Restore-L spacecraft, which is designed to service and refuel a satellite in low-Earth orbit. Once deployed, the SPIDER will assemble a communications antenna and composite beam to demonstrate that space-based construction is possible.

Formerly known as "Dragonfly", the SPIDER is the result of NASA's Tipping Point program, a partnership between the space agency and 22 U.S. companies to develop technologies essential for human and robotic space exploration. Developed by California-based Space Systems Loral (SSL) - which has since been acquired by Maxar Technologies - this robot is basically a lightweight 5-meter (16-foot) robotic arm.

As part of a $142 million contract signed with NASA, SPIDER will assemble seven elements to form a 3-meter (9-foot) communications antenna that will communicate with ground stations in the Ka-band. It will also construct a 10-meter (32-foot) lightweight composite spacecraft beam - using technology developed by Washington-based aerospace company Tethers Unlimited - to demonstrate that structures can be built in space.

As Jim Reuter, associate administrator of NASA's Space Technology Mission Directorate (STMD), said in a recent NASA press statement:

“We are continuing America’s global leadership in space technology by proving we can assemble spacecraft with larger and more powerful components, after launch. This technology demonstration will open up a new world of in-space robotic capabilities.”

The launch of the SPIDER as a payload of the Restore-L mission (currently scheduled for the mid-2020s) is part of phase two of the Tipping Point partnership, whereas phase one consisted of Maxar and other contractors demonstrating their designs in a ground-based setting. The latest demonstrations will take place in space and validate the sophisticated technologies involved.

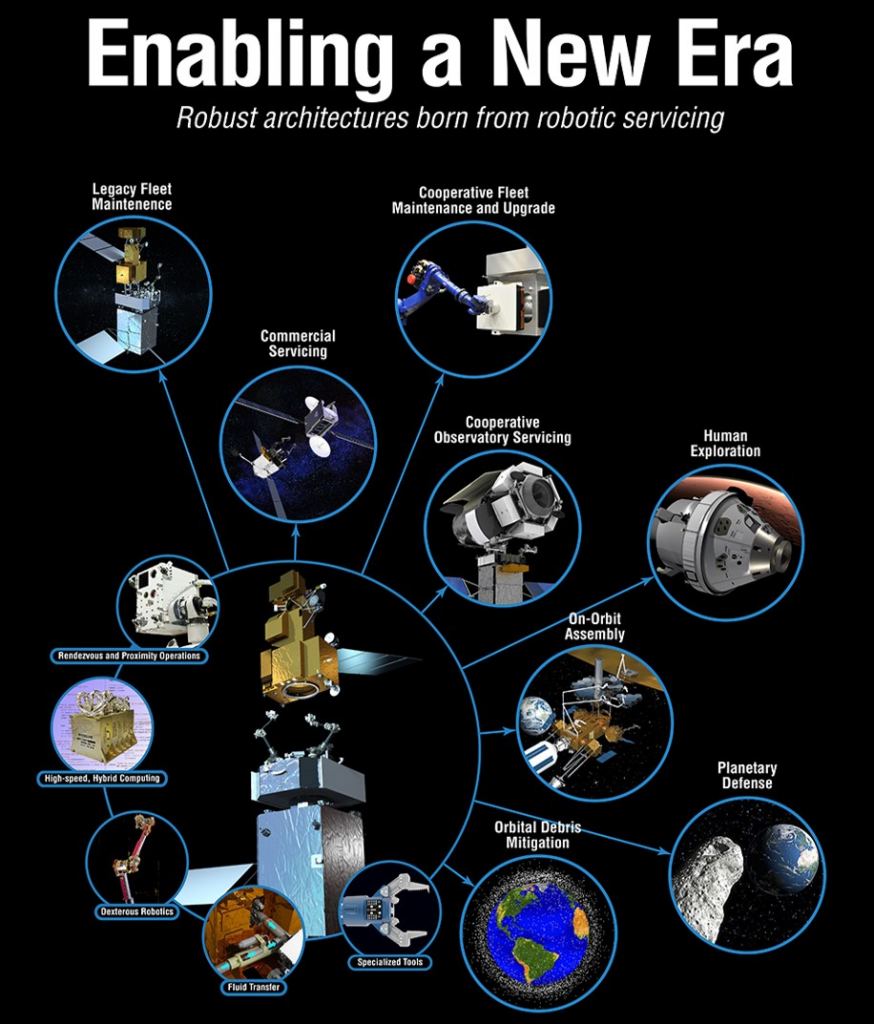

These and similar technologies that are currently in development are expected to have significant implications for government and commercial missions to space. In addition to telecommunications, orbital debris mitigation, and the commercialization of Low Earth Orbit (LEO), it also has benefits that extend to the construction of large space telescopes, spacecraft, and even planetary defense!

And of course, there are also the many applications for human space exploration, which includes crewed missions to the Moon and Mars. As Brent Robertson, project manager of Restore-L at NASA's Goddard Space Flight Center, explained:

“In-space assembly and manufacturing will allow for greater mission flexibility, adaptability, and resilience, which will be key to NASA’s Moon to Mars exploration approach."

By relocating manufacturing capabilities to LEO, government and industry are once-again poised to significantly reduce the cost of space exploration. In this respect, SPIDER is well-paired with a project like Restore-L, which is developing a suite of technologies that will enable the refueling and servicing of satellites in space. As part of the larger orbital refueling concept, the ability to do this is expected to cut costs even more.

The SPIDER payload team includes Maxar Technologies, Tethers Unlimited, the West Virginia Robotic Technology Center. Assistance and support are also being provided by NASA's Langley Research Center.

*Further Reading: NASA*

Universe Today

Universe Today