Following the explosion of an oxygen tank in Apollo 13’s Service Module on April 13, 1970, approximately 56 hours into the mission, the situation was bleak. With the Command Module (CM) without any power, the Lunar Module (LM) was activated as a life boat to sustain the crew. The task ahead – to save the spacecraft and the crew, and get them home again — would require an incredible amount of innovation by both the Apollo 13 astronauts and the engineers back on Earth.

The explosion caused the loss of the main source for oxygen, water, and most importantly, electrical power for the CM. With only 15 minutes of power left in the CM, astronaut Jack Swigert powered down the CM while Jim Lovell and Fred Haise got the LM up and running.

For engineers on the ground, one of the biggest concerns was maintaining enough electrical power in the LM and then creating enough power in the CM to power it back up again for reentry to Earth.

At the Manned Spacecraft Center in Houston, there were several teams of engineers providing expertise and support on the various components and phases of the mission. There were Staff Support Rooms for all the main console positions in Mission Control in the Flight Dynamics SSR; the Vehicle Systems SSR provided expertise and in-depth analysis on the Command and Service Module and the Lunar Module; and Spacecraft Analysis (SPAN) Room provided detailed information on spacecraft operations.

One unique support room was called the Mission Evaluation Room (MER). Most other support teams contained experts for specific systems, but the MER held a diverse team of engineering experts across several different disciplines for both the spacecraft and the crew. Those in the MER were all engineering experts for their systems, and the MER held 100 engineers or more, depending on the what was happening during the mission.

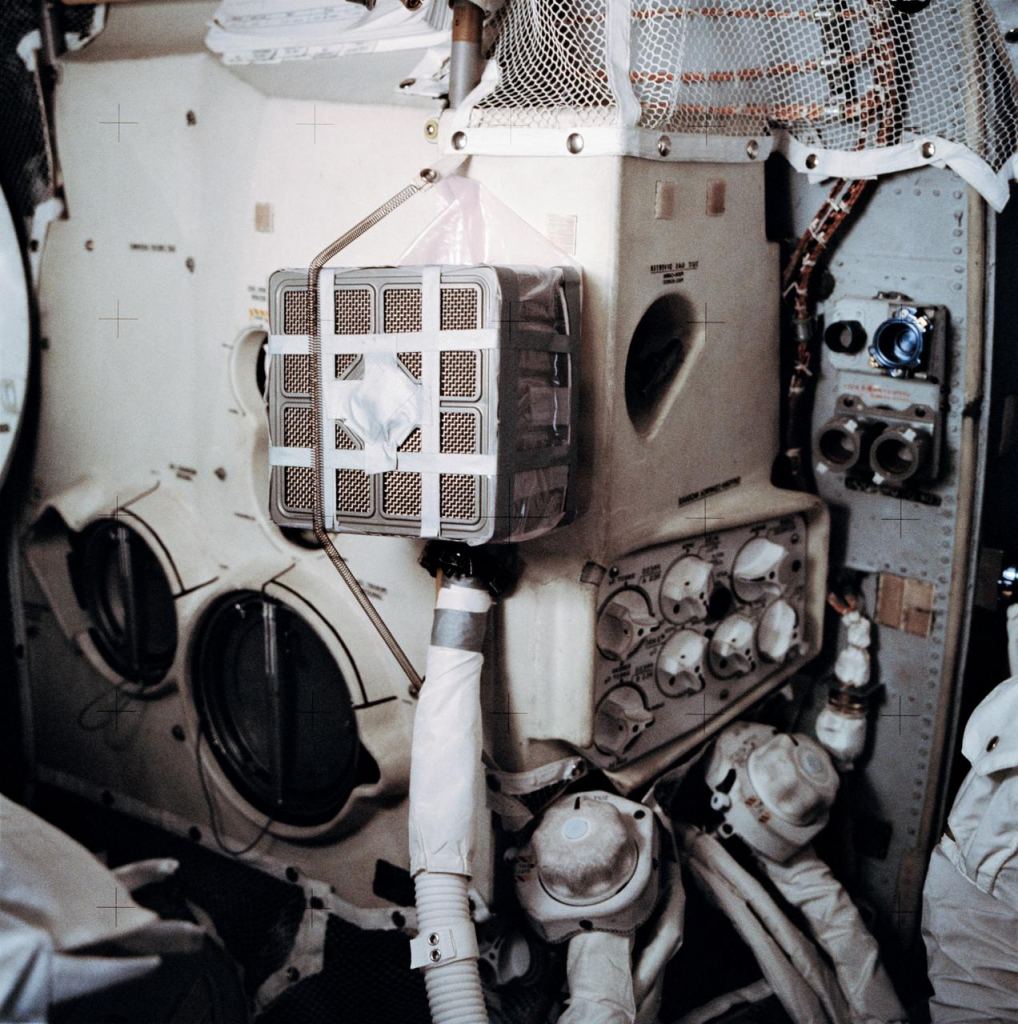

For Apollo 13, the MER engineers faced several formidable hurdles. The MER was instrumental in many tasks, such as figuring out how to rig the carbon dioxide filtration system in the Lunar Module (LM) – which was serving as a life boat for the crew – and enabled the use of the square Command Module filters to fit in the LM’s system, which normally used round filters. The MER engineers helped determine, the life of the consumables on board since the LM was built for only a 45-hour lifetime (and it needed to keep the crew alive for over 80 hours); they helped calculate what attitude to burn the LM descent engine to provide a quick return home, and the MER helped write the new procedures powering up the cold Command Module for reentry to Earth.

Electrical engineer Gary Johnson worked in the MER in the CSM’s Electrical Power Distribution and Sequencing position.

“When the explosion of the SM oxygen tank occurred [at 9:08 pm on April 13th],” said Johnson, “I was in the MER and did not leave until the next morning. By then the CSM was completely unpowered and the main activity was with the engineers supporting the active LM systems.”

The 2,181 ampere hours in the LM batteries were thought to be enough, but only if the crew turned off every electrical power device that was not absolutely necessary. This included some of the environmental systems, which created frigid conditions inside the spacecraft . It is estimated it dipped to 38 degrees F.

Once the LM power situation appeared stable, thoughts turned towards the requirements for powering up CM for reentry. (The LM couldn’t be used to reenter Earth’s atmosphere since it didn’t have a heat shield.)

There were 3 extra batteries in the Command Module to provide power for reentry, but after the explosion, they had been tapped for a short time to provide power when the fuel cells in the CM shut down. Two of three batteries were near full 40-amp-hour strength, but the third only had about half that amount. On a normal reentry, they would require at least 70 to 80 amp hours, but no one wanted to cut it that close on a mission that had so much going against it.

Could there possibly be a way to recharge the CM reentry batteries? Johnson recalled a procedure he had developed quite some time before Apollo 13, but it wasn’t quite what the situation called for.

“Prior to Apollo 13, I had thought about how to possibly use the CM’s battery charger to charge the LM batteries if needed,” Johnson recalled. “I had worked with the LM Electrical Power Subsystem Manager, Art Campos (Arturo B. Campos) and we developed a procedure using an on-board umbilical to electrically connect the battery charger output on a CM bus to the LM bus.”

Johnson went back to his office to find the memo covering this procedure. He, Campos and others in the MER started developing a plan to reverse the process to charge the CM batteries for the reentry. It was never in the original design to be able to charge the CM batteries from the LM, but the idea was to use the original procedure in reverse to trickle-charge power from the large lander batteries to the modest capacity entry batteries.

The MER engineers delivered the procedure to Mission Control, who radioed up the steps to the crew. The process took about 15 hours to charge the weak battery. There was one heart stopping moment, however. Lovell recalled that one of the CM batteries vented with such force that it momentarily dropped off line. “We knew we were finished if we permanently lost that battery,” Lovell said, but it remained stable for the remainder of the mission.

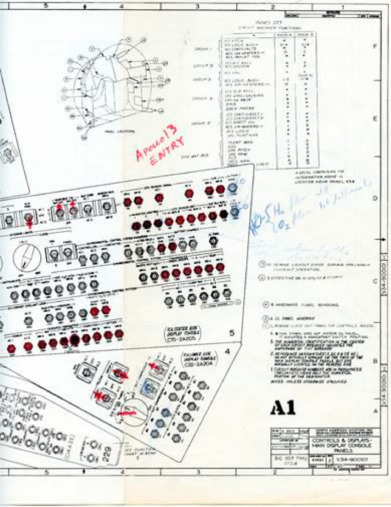

Johnson was also part of the team that worked on the CM power up configuration for reentry after its long, cold sleep. This was something that had never been done before. The procedures had to be tested thoroughly in the Apollo spacecraft simulators before being radioed up to the crew. The documents for this innovation were prepared in just three days. Usually the development of new procedures like this took months.

“I marked up the Controls & Displays Panel drawing using a red marker to show switch positions and circuit breakers that were to be closed and blue for circuit breakers to be open,” Johnson said. “I went around the MER to the engineers of the different subsystems to get the information from them on what needs to be enabled to turn on and what should be off. That information was used to markup the C&D Panel drawing and information from that was provided to Mission Control.”

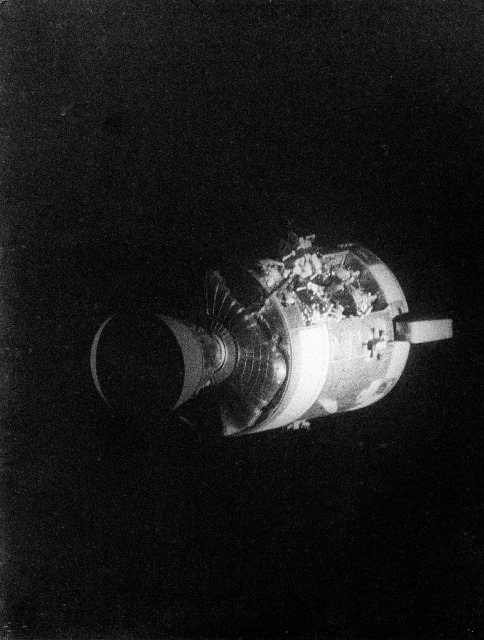

Four hours before landing, the astronauts jettisoned the Service Module, which even though was crippled and useless, had been kept attached to the CM to protect the heat shield. In jettisoning the SM, the astronauts were finally able to see the damage caused by the explosion.

“I’m glad we weren’t able to see the SM earlier,” Lovell later wrote. “With one whole panel missing, and wreckage hanging out, it was a sorry mess as it drifted away.”

Then it was time to power up Odyssey. The procedure developed by the engineers went off without a hitch, even though the walls, ceiling, floor, wire harnesses, and panels inside the CM were all covered with droplets of water.

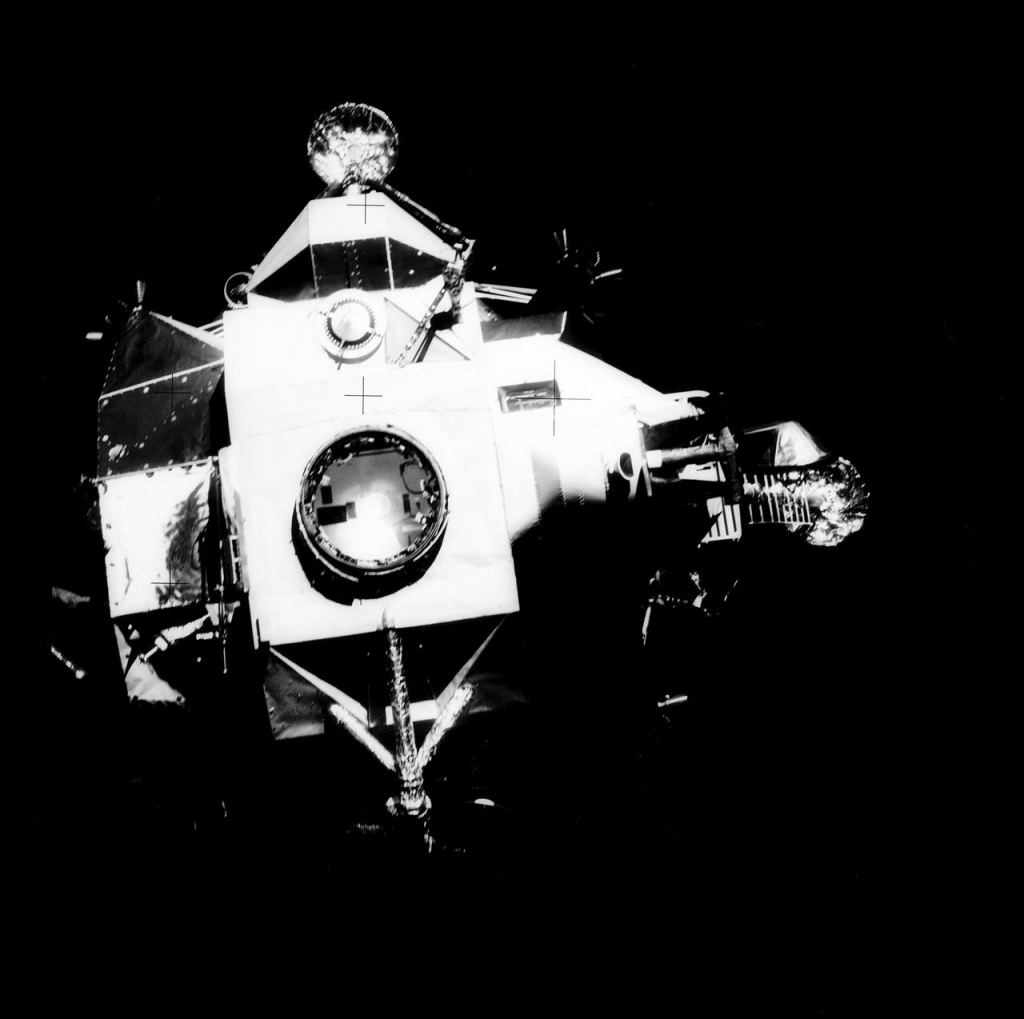

Then it was time to button up and jettison Aquarius, their LM that had kept them alive and safe, and prepare for reentry.

The first article in this series: The Barbecue Roll, and the next article in this series looks at the nail-biting reentry sequence. You can read more about the behind-the-scenes engineering for Apollo 13 in our original series of articles titled “13 Things That Saved Apollo 13,” and “13 MORE Things That Saved Apollo 13.” Our thanks to NASA engineer Jerry Woodfill for his ideas and insights for these series of articles.