The International Space Station (ISS) is not only the largest and most sophisticated orbiting research facility ever built, it is arguably the most important research facility we have. With its cutting-edge facilities and microgravity environment, the ISS is able to conduct lucrative experiments that are leading to advances in astrobiology, astronomy, medicine, biology, space weather and meteorology, and materials science.

Unfortunately, the cost of transporting experiments to and from the ISS is rather expensive and something only a handful of space agencies are currently able to do. To address this, the Japanese Aerospace Exploration Agency (JAXA) and Tiger Corporation partnered in 2018 to create a new type of container that would cut the cost of returning samples to Earth. With the success of their initial design, JAXA and Tiger are looking to create a reusable version that will allow for regular sample returns from the ISS.

Established in 1923, Tiger is an international corporation based in Osaka, Japan, that specializes in vacuum insulation and related technologies. This technology, which the company has used for decades to create insulated water bottles, also has applications for space exploration. In recent years, JAXA began investigating the technology to create storage containers that could keep experimental samples cool during their return to Earth.

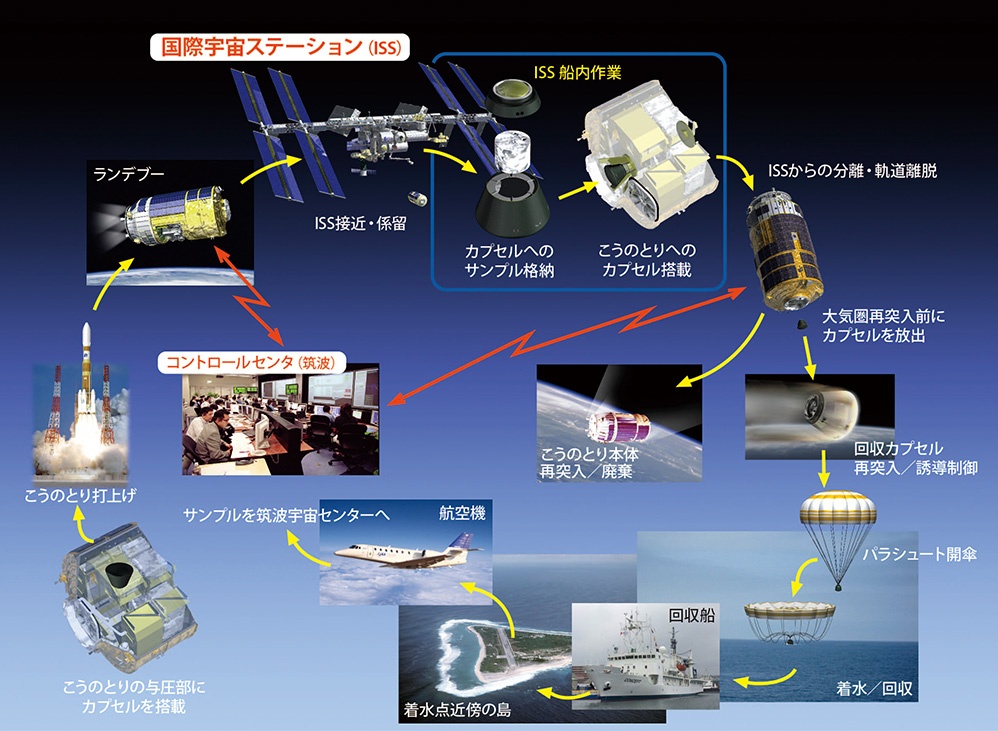

In September 2018, JAXA launched the Kounotori 7 (HTV-7) mission, the seventh flight of the H-II Transfer Vehicle (HTV). While transporting supplies to the ISS, JAXA decided to use this flight to validate a new method for transporting samples of protein crystals (which were part of a growth experiment conducted inside Japan’s Kibo Laboratory Module) back from the ISS.

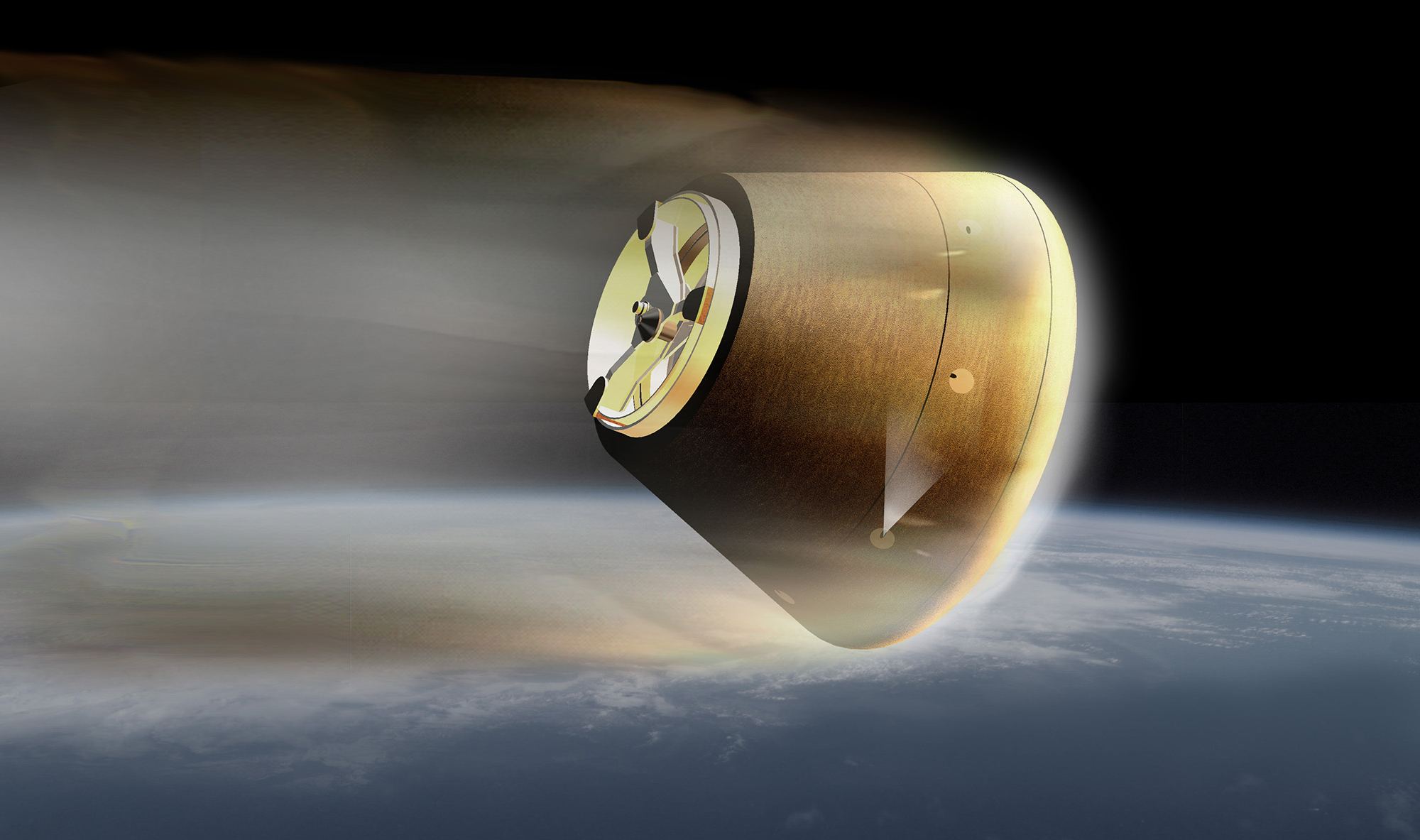

This consisted of a special sample container (NPL-A100) co-developed by JAXA and Tiger that was placed inside the HTV Small Re-entry Capsule (HSRC). Since the re-entry capsule was too small to rely on an electrical cooling system, JAXA and Tiger needed a sample container that relied on “passive insulation” methods to keep its contents at stable temperatures.

In the end, they used the same technology Tiger relies on to create stainless steel thermal bottles to develop a double-walled, vacuum-insulated vessel that weighed about 9.7 kg (21.4 lb). As Keiji Nakai, who is the manager of the Product Development Group (3rd section) at Tiger explained to Universe Today via email, the container had to meet some very strict requirements:

“The double-walled, vacuum container for this mission had to maintain the temperature inside the container at 4 °C ± 2 °C (39.2 °F ± 3.6 °F) over the course of four or more days and protect the container from the enormous 40G impact when landing in the ocean upon returning to Earth.”

A number of cold packs were also included in the capsule to ensure that the container’s temperature remained stable. The mission was a success and represented a major milestone for JAXA, which previously did not have the option of independently recovering materials from the ISS. Like many space agencies taking part in the ISS, JAXA had been dependent on Roscosmos and NASA to provide transportation services.

The next step in the JAXA-Tiger collaboration involves the creation of a smaller, lighter, and more durable container that can keep samples stable at lower temperatures and for longer. But the most stringent requirement is that it must be durable enough to be used more than once. Said the representatives at Tiger, these and other specifications have gone into the design of the second generation NPS-A100 container:

“We have reduced the weight of the container from 9.7 kg (21.4 lb) to nearly 3 kg (6.6 lb) while also making it more compact. With the addition of ice packs, it will maintain temperatures inside of 20 °C ± 2 °C (68 °F ± 3.6 °F) for at least twelve days, from the time the re-entry capsule leaves the ISS to when it lands back on Earth. We have also made the container more durable so it lasts at least three years or six missions.”

The NPS-A100 is likely to be transported to the ISS as part of the CRS-22 commercial resupply mission that is scheduled for early June and will involve a SpaceX Crew Dragon transporting supplies and experiments to the ISS. Once again, the container technology will be used to return protein crystals that are part of ongoing biomedical research taking place in the Kibo Laboratory inside the ISS’s Japanese Experiment Module (JEM).

This research is leading to advances in the field of medicine and the development of new cures and medicines. Beyond sample containers, the technology resulting from this collaboration also has numerous commercial and industrial applications. These include transportation solutions for medical samples and reagents that require storage under strict temperature conditions.

It could also lead to new applications for thermal management in electric and hybrid cars. But perhaps the most interesting application is in the development of next-generation building materials that could provide high levels of insulation in extreme environments – such as Antarctica (where research stations need to conserve heat!) and even on the Moon and Mars!

“The potential applications of our vacuum insulation technology are limitless,” states Tiger on their website. “This technology will support cutting-edge fields in every industry, helping them lead us towards a dynamic, exciting future.”

Update: It has since been confirmed that the new vacuum container will be launched aboard a Crew Dragon spacecraft on June 3rd to the ISS, as part of the CRS-22 cargo resupply mission. The Tiger Corporation also plans to launch a new line of products for the US market, which is tentatively planned for September.

Further Reading: JAXA, Tiger Corporation

I guess a railgun that fires things backwards at 17,000mph would give G-Force problems