One of the least known of NASA’s funding mechanisms is the Small Business Innovation Research (SBIR) program. This program, required by the Baye-Doyle Act of 1980, earmarks a piece of every US Federal agency’s budget (including NASA) for the development of small businesses to commercialize new technologies. NASA’s SBIR program usually focus on commercializing technologies that are useable in space, and many times fund a university doing some work in addition to the small business that received the grant. A company called Air Squared Inc, based in Broomfield, Colorado, recently received one of these SBIR grants, and teamed up with a mechanical engineering lab at Purdue University and Whirlpool, one of the world’s appliance giants, to produce a necessary component for any long-term space mission – a refrigerator.

While it may seem a rather mundane way to spend research funding, getting a fridge to operate in space is no easy task. There are two main problems that need to be addressed by a refrigerator in space. First is a lack of gravity which can affect a fridge’s compressor. Second is the system’s orientation, which can cause havoc with the vapor compression cycle that the fridge uses to cool.

Credit : Purdue Department of Mechanical Engineering

Let’s look at gravity first. Fridges have a machine called a compressor, which is the machine that can be heard operating when a fridge turns on. The compressor’s job is to pressurize the “hot” line of refrigerant liquid, so that it can participate in the vapor cycle described below. The compressor itself has moving parts in it, which are usually lubricated by oil, much like a gasoline car engine would be.

The problem is, when there is no gravity, that oil is not sure where to go, and could spread itself too thin to be useful in lubricating the compressor, causing it to seize up. Without a compressor, the entire refrigeration system is thrown out of whack.

Credit: Lesics YouTube Channel

Another way to throw that system out of whack is to change its orientation. A key component of refrigerators is the throttling system, which essentially acts as a bridge between the hot liquid and cold vapor lines. The throttling system forces a significant pressure drop in the liquid of the hot line, which causes evaporation of some of that liquid. Evaporating that liquid requires energy, which is drawn from the heat of the liquid that is evaporated, making the vapor on the other side of the throttle where it condenses much colder.

The problem is that if the orientation of the fridge flips, the liquid and vapor could switch places, causing bubbles could form and destroying the compressor trying to pressurize the liquid. This is why you are not supposed to lay a fridge flat when moving it.

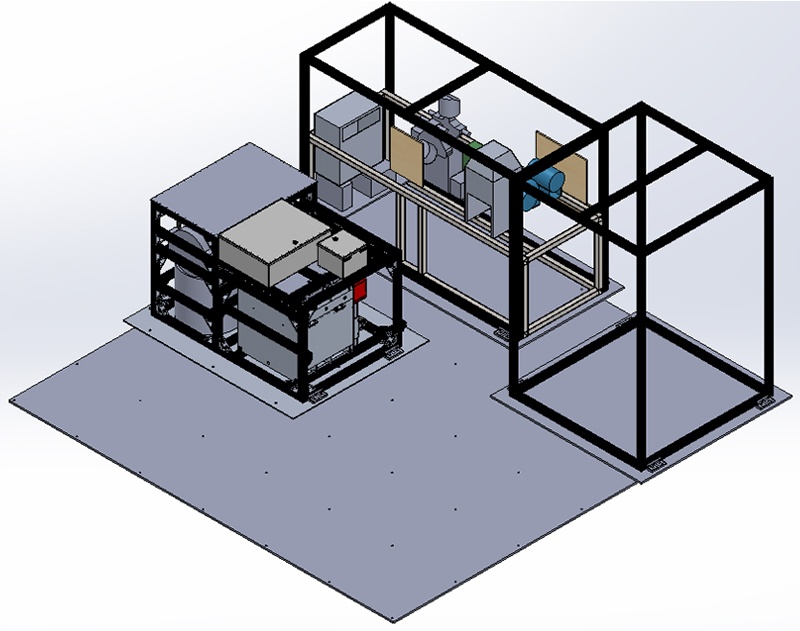

Credit: Air Squared, Inc.

If a spacecraft travels to another gravity well, it would be very possible that what was considered “up” during its launch would be considered “down” once it landed somewhere new, causing the entire process be thrown into chaos. Any typical refrigeration system is therefore unusable in any environment that changes its orientation like that.

Air Squared and Purdue think they have a better solution. First, Air Squared has developed a compressor that doesn’t require oil, eliminating the possibility that it would destroy itself in low gravity environments.

Credit: Purdue University / Jared Pike

The details on how they will deal with the orientation issue isn’t quite as clear, however it would only come into play once gravity is again a factor. The solution could be as easy as designing a compressor that would switch directions and exchange where the pipes are run, allowing it to provide pressure to either side of the throttle depending on the system’s orientation.

Luckily, they will have plenty of opportunities to test their solutions on both problems. The program received funding from the Flight Opportunities program, which will allow the team to fly their fridge design on four “microgravity” flights. The flights, run by the Zero Gravity Corporation’s weightless research lab, simulate about 20 seconds of microgravity dozens of times over the course of a flight.

If it passes its microgravity tests, the next step would be to test it in space. It is not the first time refrigeration has been attempted in microgravity. In fact, the ISS currently has a refrigeration system that is used to store biological samples. However, it is bulky, and requires significantly more power than a normal fridge on Earth. Since power is at a premium in space, this makes it a less than desirable design.

The Air Squared / Purdue prototype is much more user friendly. At about the size of a microwave, it is designed specifically to keep food cold. Such a refrigeration system could increase the shelf life of astronauts’ food from about 3 years to more like 5 or 6.

That increased shelf life would be invaluable for some of the longer manned missions coming up on the space exploration roadmap. There’s still plenty of research left to do and things left to invent, but hopefully, one small start-up in Colorado, with support from some of the finest engineering organizations in the world, will be able to introduce consistently reliable cooling to space exploration missions.

Learn More:

Purdue – Astronauts need a fridge. Engineers are building one that works in zero gravity – and upside down.

Interesting Engineering – Engineers Are Developing a Zero-G Refrigerator For Space Missions

Lead Image:

Head of Purdue’s Mechanical Engineering Department Eckhard Groll (left) and graduate student Leon Brendel stand next to their reorientable refridgerator.

Credit: Purdue University photo / Jared Pike