Materials science has once again come through for space exploration. Researchers at the Laser Interferometer Gravitational-Wave Observatory (LIGO) have developed a coating that could increase the sensitivity of LIGO by almost an order of magnitude. That would increase the detection rate of the gravitational waves the observatory is seeking from about once a week to once a day, mainly due to the increased volume of space that the observatory's interferometers would be able to collect signals from.

It may be shocking that something as simple as a coating could dramatically impact a scientific experiment, but this was not just a simple coating. It was specially designed to turn the glass placed in LIGO's interferometer into a mirror. Having a highly reflective mirror is essential to having a highly sensitive instrument, as the mirrors reflect the laser beams used to measure the gravitational waves themselves. However, the coatings used to make these mirrors reflective can introduce a tiny amount of noise to the instrument usually caused by the material itself absorbing some heat from the beam. Unfortunately, at the sensitivities LIGO is looking for, that small amount of noise could have an outsized impact on results.

Therefore, the development of a better coating has been central to efforts to improve LIGO's sensitivity. Now, Gabriele Vajente, a senior research scientist at LIGO and Caltech, thinks he has a solution. Perhaps more importantly, he has developed a tool for finding better solutions in the future.

The current best solution that Dr. Vajente and his team came up with is a combination of titanium and germanium oxide, which crucially absorbed the least amount of energy into the mirror itself. That absorption is the root cause of the noise introduced into the system. Less absorption, therefore, means less noise.

The coating will be applied to the 40 kg (88 lb) mirrors using a technique similar to atomic layer deposition (ALD). Germanium and titanium atoms are combined with oxygen and then deposited directly onto the mirror.

Testing the effectiveness of the coating is an entirely different matter. Usually, testing would take upwards of a week, limiting the number of different material combinations that could be tested. Dr. Vajente and his team then developed a technique where that testing time would be completely automated and take around eight hours.

UT video describing LIGO's latest observational campaign.That quick turn-around time allowed the team to iterate over many possible material structures in ways that had not previously been possible. The resulting germanium and titanium dioxide coating could potentially decrease the noise in LIGO's interferometer mirrors by half, which, through the beautiful laws of geometry and math, would allow them to detect signals from an area of space either times bigger than ever before.

Before that considerable improvement can start making a difference, it must be implemented. Unfortunately, with the project's current timelines, it seems the earliest observational run the new coating might be used on will happen only around 2025. The next campaign, LIGO's fourth, planned to start in 2022, is too soon to adopt an entirely new coating technology.

Luckily, the underlying coating technology and test apparatus could be useful in other fields, such as telecommunications and semiconductor manufacturing. According to David Reitze, the executive director of LIGO, "This is the biggest advance in precision optical coating development for LIGO in the past 20 years". Now that is an accomplishment to celebrate.

Learn More:

CalTech - Extending LIGO's Reach Into the Cosmos

Physical Review Letters - Low Mechanical Loss TiO2:GeO2 Coatings for Reduced Thermal Noise in Gravitational Wave Interferometers

Optica - Low-Noise Optical Coatings Could Swell LIGO’s Reach

Hi Tech Glitz - LIGO receives new mirror coatings to expand its range

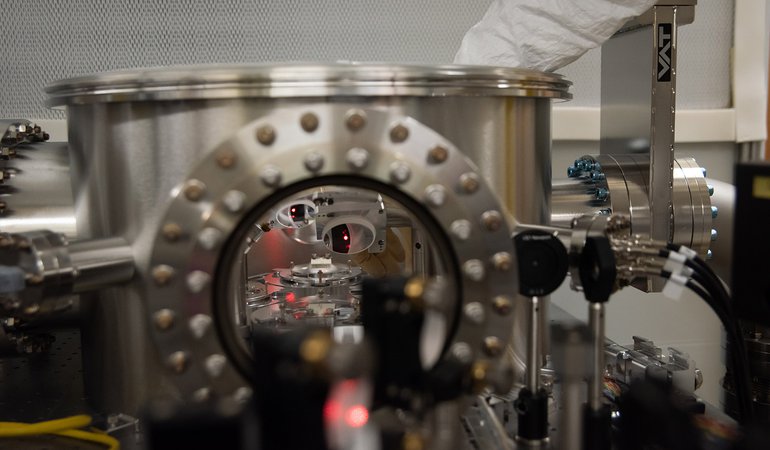

Lead Image:

New coating on a sample of glass.

Credit - CalTech

Universe Today

Universe Today