For years, China has been dropping hints about its *Long March 9* (CZ-9) rocket, a three-stage super-heavy variant of the Long March family. This launch vehicle will reportedly be capable of transporting up to 150,000 kg (165 tons) to Low Earth Orbit (LEO) and 54,000 kg (59.5 tons) to a trans-lunar injection. On March 2nd, the China Academy of Launch Vehicle Technology (CALT) announced (via the Chinese social media platform Weixin) that it had finished building the first propellant tank for the CZ-9.

The news was accompanied by pictures that showed the finished tank and the many components that went into making it - and they are massive!

The propellant tank measures 10 meters (~33 feet) in diameter, making it the largest developed by China so far. This is slightly wider than the main propellant tanks used by SpaceX's Starship (9 m; 30 ft) and NASA's Space Launch System* (8.4 m; 27.5 ft). It's also twice the size of the first stage on the Long March 5* ("Fat Five") rocket, currently the workhorse of the China National Space Agency (CNSA). It also represents a significant feat of engineering and lays the foundation for the engineering and development of heavy-duty launch vehicles.

It also makes China the third country (behind Russia and the U.S.) to realize the development of an ultra-large storage tank. Said Wang Hailu, editor of the CALT statement:

"The super-large-diameter storage tank structure is an important part of the heavy-duty rocket body structure, and its diameter directly affects the rocket body diameter, carrying capacity, and scale. Compared with the 5-meter-diameter storage tank structure of the new generation of launch vehicles currently in service in my country, the storage tanks of heavy-duty launch vehicles have to be expanded to the order of 10 meters, and the size and load have increased significantly. The difficulty is not small."

According to Hu Zhenggen, a researcher with the Beijing Aerospace Propulsion Institute and the deputy chief designer of the CZ-9 at China's Rocket Academy, the challenges were not a simple matter of scaling the tank by a factor of two. Structurally speaking, the exponential volume of the 10-m tank means that it has to be much stronger to house several times the propellant but also thin and light enough to minimize the rocket's overall launch weight.

Because of this, the development of the CZ-9 and its components also highlights advances made by China in terms of advanced materials and high-end manufacturing. This includes friction stir welding (FSW), where heat is generated by a rotating tool to join sections of material without melting them. Other challenges involved preparing large-diameter sheets and components with the precise shape and properties needed to balance strength with low weight.

The development process - including materials, design, component forming, assembly and welding, and assessment - took six years and was conducted by more than 20 Chinese research groups. Previously, the team announced the creation of several of the tank's key components, including an integral transition ring, the "melon petals" (sections of the rocket roof), and the top and bottom rings. Images of these components were included in the CALT press release (see above).

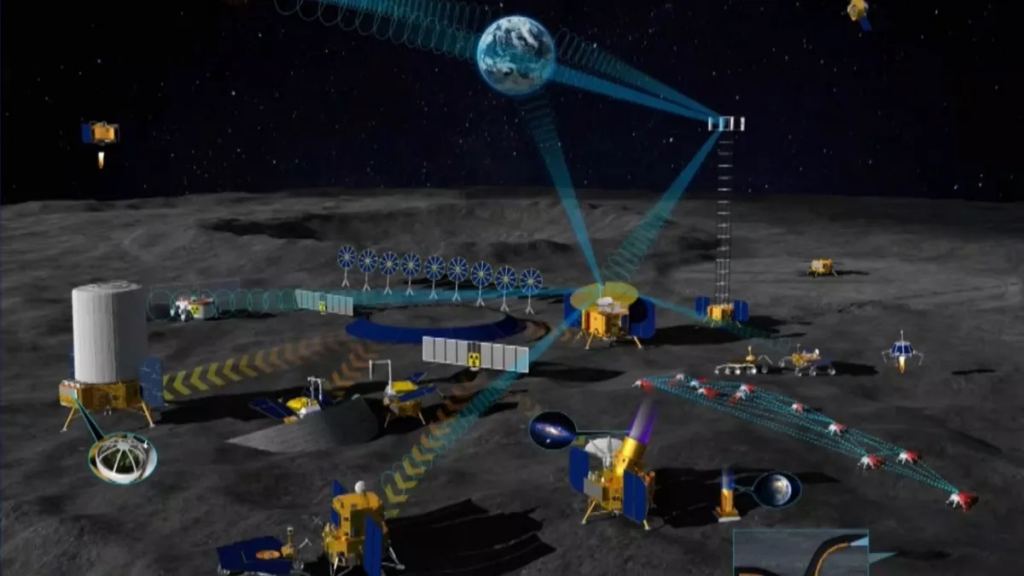

While the Long March 9* was initially designed to be expendable, China has since stated that it plans to switch to a reusable design, similar to the Starship.* Once it is ready to make its first flight (around 2030), the CZ-9 will be used to build China's proposed International Lunar Research Station (ILRS), a collaborative project with Roscosmos intended to rival NASA's Artemis Program. Like NASA, the ILRS mission architecture envisions the creation of infrastructure on the lunar surface, including a long-term base, a transportation facility, a research station, and a ground support facility.

This development is part of China's larger objective of becoming a space-faring power that will rival NASA. These efforts CALT include the development of anew crewed vehiclethat is expected to make its debut launch by 2027. A smaller version of the spacecraft will transport taikonauts to Low Earth Orbit (LEO) and rendezvous with the Tiangong space station, while a larger variant will land crews on the surface of the Moon. Said Wang:

"In the future, with the efforts of more project teams of the Rocket Academy, it is believed that heavy-duty launch vehicles will be getting closer and closer to us. At that time, our country's ability to independently enter space will take a big step, and the pace of Chinese people's exploration of space will also take greater and farther steps."

*Further Reading: Weixin*

Universe Today

Universe Today