Through the Artemis Program, NASA will return astronauts to the lunar surface for the first time since *Apollo 17* landed in 1972. Beyond this historic mission, scheduled for September 2026, NASA plans to establish the infrastructure that will enable annual missions to the Moon, eventually leading to a permanent human presence there. As we addressed in a previous article, this will lead to a huge demand for cargo delivery systems that meet the logistical, scientific, and technical requirements of crews engaged in exploration.

Beyond this capacity for delivering crews and cargo, there is also the need for transportation systems that will address logistical needs and assist in exploration efforts. These requirements were outlined in a 2024 Moon to Mars Architecture white paper titled " Lunar Mobility Drivers and Needs." Picking up from the concurrently-released " Lunar Surface Cargo," this whitepaper addresses the need for lunar infrastructure that will enable the movement of astronauts and payloads from landing sites to where they are needed the most. As usual, they identified a critical gap between the current capabilities and what is to be expected.

Once again, the authors cite the need for mobility systems in keeping with NASA's objectives, as detailed in the Moon to Mars Architecture Definition Document (ADD). As they indicate, recent analyses of integrated surface operations have highlighted the importance of transportation systems that can move cargo from points of delivery to points of use across the lunar surface. This could range from "crew logistics and consumables to science and technology demonstrations, to large-scale infrastructure that requires precision relocation."

In short, in addition to landers capable of delivering crews, supplies, experiments, and habitats, NASA's Moon to Mars program also requires vehicles and support networks that can deliver them from point A to point B. As they state, the currently defined mobility elements are either primarily for crew use or are limited in mobility. This includes elements like the Lunar Terrain Vehicle (LTV) and the Pressurized Rover (PR) - which are elements of the Artemis Base Camp - and robotic missions contracted through the Commercial Lunar Payload Services (CLPS) program.

In addition, the needs and challenges that will emerge as the Artemis Program unfolds are broken down into three segments: Human Lunar Return (HLR), Foundational Exploration (FE), and Sustained Lunar Evolution (SLR). The HLR segment includes the Artemis III mission, currently scheduled for September 2026, where a crew of two will land on the lunar surface using a Starship HLS. The FE segment will coincide with Artemis IV* and Artemis V* (2028 and 2030), where crew sizes will expand from two to four, and the necessary infrastructure will expand.

After that, during the SLR segment, NASA plans to mount a mission a year and establish a permanent lunar habitat. Throughout this period, the demands for payloads and transportation systems will exceed current capabilities, limited to 15,000 kg (33,070 lbs) of cargo. Similar to what NASA related in their Lunar Surface Cargo whitepaper, accomplishing key mission objectives will require cargo of sizes and masses beyond these capabilities, creating the need for additional solutions.

Separation and Transportation

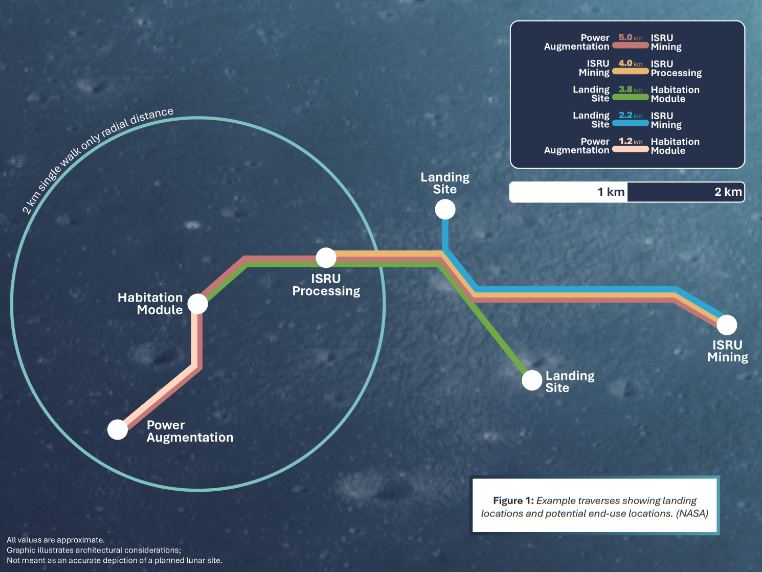

As the authors state, a major issue on the lunar surface affecting mobility is the need for separation between landing sites and points of use. This separation is motivated by several factors, including science objectives, lighting conditions, and safety considerations. In short, crew vehicles, habitats, and key infrastructure will be positioned at a distance from landing sites so as not to be affected by darkness caused by the landers' shadow, contamination by the landers, and regolith or blast ejecta created by engine plumes. Based on the level of concern, separation distances are broken down into three tiers:

- Separation from lander shadowing (tens of meters; tens of yards)

- Lander blast ejecta constraints due either to separation between the lander and existing infrastructure or lander ascent(>1,000 m; ~1090 yards)

- Support for aggregation of elements in ideal habitation zones from available regional landing areas(up to 5,000 m; ~5470 yards)

In addition, NASA's Moon to Mars mission architecture emphasizes the need for In-Situ Resource Utilization (ISRU), such as water ice, regolith, and minerals. NASA also recognizes the need to select habitation and hibernation sites that minimize the exposure to darkness from shadows caused by the local topography and the inclination of the Sun during lunar nights (which last two weeks at a time). This is easiest at higher elevations and on top of crater ridges. This necessitates two things:

- *Exploration, habitation, and power sites will need to be located far from landing and ISRU sites*

- *Traverses from landing to habitation zones could encounter slopes of up to 20 degrees*

As the authors state, these overlapping challenges can be met by ensuring systems are in place so mission elements can move away from landers once they are deployed on the surface:

"This could be done using independent or integrated mobility systems. The frequency of traverses between downslope and upslope locations would be driven by the cadence with which landers deliver cargo to the lunar surface and the mass that a given mobility system can carry on each traversal. Integrated architecture operations will necessitate non-trivial relocation and aggregation ranges for cargo and assets."

Transport Capabilities

During the FE segment of the Artemis Program, NASA plans to expand surface crews from two to four, which will need to operate on the surface for about 30 days. This will require a wide range of mobility needs that can accommodate payloads of varying size and mass and over a range of distances. These include:

- Smaller technology demonstrations: 500 to 2000 kg (~1100 to 4410 lbs)

- Logistic Elements per crewed surface mission: 2,000 to 6,000 kg (~4410 to 13,230 lbs)

- Habitation Systems: 12,000 to 15,000 kg (~26455to 33,070 lbs)

The authors acknowledge that current mobility elements could provide some cargo relocation capabilities - the LTV, for example, can accommodate 800 kg (~1764 lbs) of cargo when uncrewed. However, according to the NASA team's analysis, the mobility capacity falls short of demand by 1,000 to 15,000 kg (2,200 to 33,070 lbs) per asset for ranges of 50 to 5,000 m (~55 to 5470 yards). Moreover, the "frequency of relocation needs" (i.e., how often payloads need to be moved) will vary considerably, ranging from single operations for large elements to multiple trips a year for containers and smaller cargo.

Conditions

The authors also address how lunar conditions are important when developing mobility systems. One of the greatest hazards on the Moon is regolith (aka. "moondust"), the fine silicate powder that covers much of the surface and sticks to everything it comes into contact with. There are lighting conditions where parts of the South Pole region will be shadowed due to the inclination of the Sun and permanently shadowed regions (PSRs) that experience perpetual darkness. Last is the matter of the terrain, which can be rocky or covered by 1 to 10 m (3.3 to 33 ft) of regolith and where slopes of more than 10 degrees are common.

This combination of factors, they argue, "creates a significant technological gap between existing systems and mobility demands for future exploration." For starters, energy systems must provide enough power so vehicles can maintain sufficient speeds and carrying capacity and can operate during lunar nights. The authors also recommend conducting more studies on regolith mitigation strategies to prevent wear and tear and the effects regolith could have on electro-mechanical systems. They also stress the need for sufficient autonomy and/or teleoperation, allowing greater flexibility and range.

These autonomous systems must contend with the challenging lunar terrain, map the local topography, recognize obstacles and unpassable regions, and identify optimal pathways to reach their destinations. As the authors note, these systems could offer increased flexibility for mission planning and increase the speed of mobile assets, especially in areas where the terrain interferes with communications and makes remote operations impossible.

In summary, the "Lunar Mobility Drivers and Needs" whitepaper identifies some robust requirements for creating a permanent human presence on the Moon. This will entail moving cargo and assets across the lunar surface from landing sites to destinations 5 to 5,000 meters (~5.5 to 5470 yards) away. It must also be able to accommodate payloads of up to 12,000 kg or more, which is significantly higher than the current capabilities of the proposed LTV - 800 kg (~1765 lbs).

In addition, the paper indicates that energy and environmental considerations are crucial to the design process. It is not simply a matter of scaling up small-scale mobility systems to create large-scale ones. Lastly, the computer systems and software running future mobility systems will need to be interoperable, exchanging information between vehicles and base sites, and have the ability to function autonomously or semi-autonomously.

Like the "Lunar Surface Cargo," these findings will be explored in more detail with the 2024 Architecture Concept Review (2024 ACR), which will be released later this year, along with white papers describing NASA's cargo return needs and lunar surface strategy.

Further Reading: NASA

Universe Today

Universe Today