[/caption]

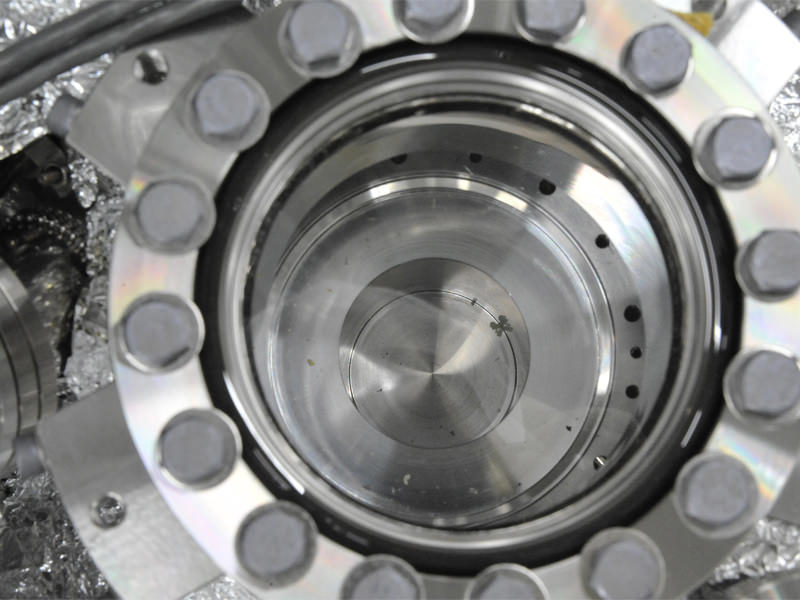

The sample return canister from the Hayabusa spacecraft has been opened, and does contain a small amount of dust particles, according to the JAXA website. This is very encouraging news! However, it is not yet known if the dust is from the asteroid Itokawa, where Hayabusa briefly touched down, or if it could be from Earth — left in the container from before launch, or it possibly could have made its way in there during the landing/post landing handling. “Material on the planet or asteroid or particulate matter is at this stage is unknown, we will consider in detail,” is the Google translate version of the JAXA press release. According to Emily Lakdawalla at the Planetary Society, the dust grains are extremely small, about 0.01-millimeter in size, and there are about a dozen of them inside the container. This image was taken on June 28, 2010, and below is a magnified view of one of the particles.

This magnified view was taken on June 29, and shows a magnified view of one very small particle being picked up by a quartz manipulator, which appears as a stripe on the image.

It likely will take several weeks to confirm whether the particles are from the asteroid, but if so, would be the first-ever asteroid sample return.

Below is an image of Earth that Hayabusa took as it approached the home planet.

Sources: JAXA, The Planetary Society, BBC

Here’s hoping JAXA bagged something interesting!

“…left in the container from before launch…” Don’t they know? I wonder what procedures JAXA used prior to initial ‘close out’..

Please don’t sneeze!

@Torbjorn Larsson OM – I am familiar with semiconductor processing, having worked in the industry for a number of years. My guess is that they might have used a vacuum chamber purge or even plasma chamber reduction technique(s) after initial cleaning… that’s why I am curious about the method(s) actually used and wondering after the reason they are not certain about contaminate control?

Yeah… I’ve worked on quartz gas diffusion chambers (Tylan Corp.), plasma etch chambers with automated wafer handling systems (Tegal Corp.) and vacuum deposition systems (Optical Coating Labs). I know the Japanese are VERY methodical in their semicond. manufacturing – you have to be – which is why this is such a surprise that they aren’t sure…

My biggest ‘goof’ was when I specified a hard anodized coating for a wafer processing platform, which is inserted into the bottom of a plasma chamber. My boss read me the riot act! “Do you know how much that chamber cost to clean?” Then he laughed and told me that it was actually okay.. because the chamber actually worked BETTER This was due to ions from the anodize actually enhancing the plasma!

Where did all those “actually’s” come from?? ~@; ) Note to self – double check posts prior to submission.

Let’s hope it’s a bakers dozen.

@ Aqua: Cleaning is, like dilution or semiconductor processing, a stochastic process. Basically you trade off certainty for parallelism (removing several dust particles in an area by, say, wiping). Verification methods are often also cheap parallel ones (say, wiping an extra time and check a rinse for its particle content).

The opposite is show in the photo – exact, but costly in time and resource, serial processing. This is why it makes sense to verify provenance afterwards, when and where you need it.

Or it — whatever “it” was — got out and left its droppings! 😉

It brought us a bunny!

Aqua, my point is that if you use large scale processes you can’t be absolutely certain. So if you find particles you have to ascertain provenance afterwards.

Also, Lakdawalla’s article contains more information. The “dozen” particles are larger at ~ 1 mm and found “on the outside of the inner tube” so perhaps contamination. The number of small ones aren’t specified. At least they got one!

Waite and see what the particle is made of. If it is Nonobtainium, than it is probably not a contamination.

Nice. I can’t believe that it would even be possible that this was contamination – what kind of shonky sample return capsule couldn’t survive a perfectly executed landing to end up getting crap inside? Preposterous!

Anyway, they said if they even get a single grain it can be divided up and sent to scientists around the world for study, once the Japanese have had their crack. Given that even today the moon rocks are still yielding their secrets, if these are asteroidal crumbs, we should be reaping the rewards for many years to come!

Some here don’t seem to realise that the scientists are taking a cuatious approach, not declaring anything in the capsule as asteroid material until they have evidence that it is. Terrestrial and spacecraft contaminants have to be considered and ruled out first. This is right and proper, I don’t see why some seem to have a problem with this.

I’ll admit that finding hairs on cleaned surfaces is rare, but finger prints are not, nor particles.

@Torbjorn Larsson OM: NOT in MY clean room… see ISO std. 14644-1 and note there are successive or progressively cleaner specs. I assumed JAXA used the highest possible..