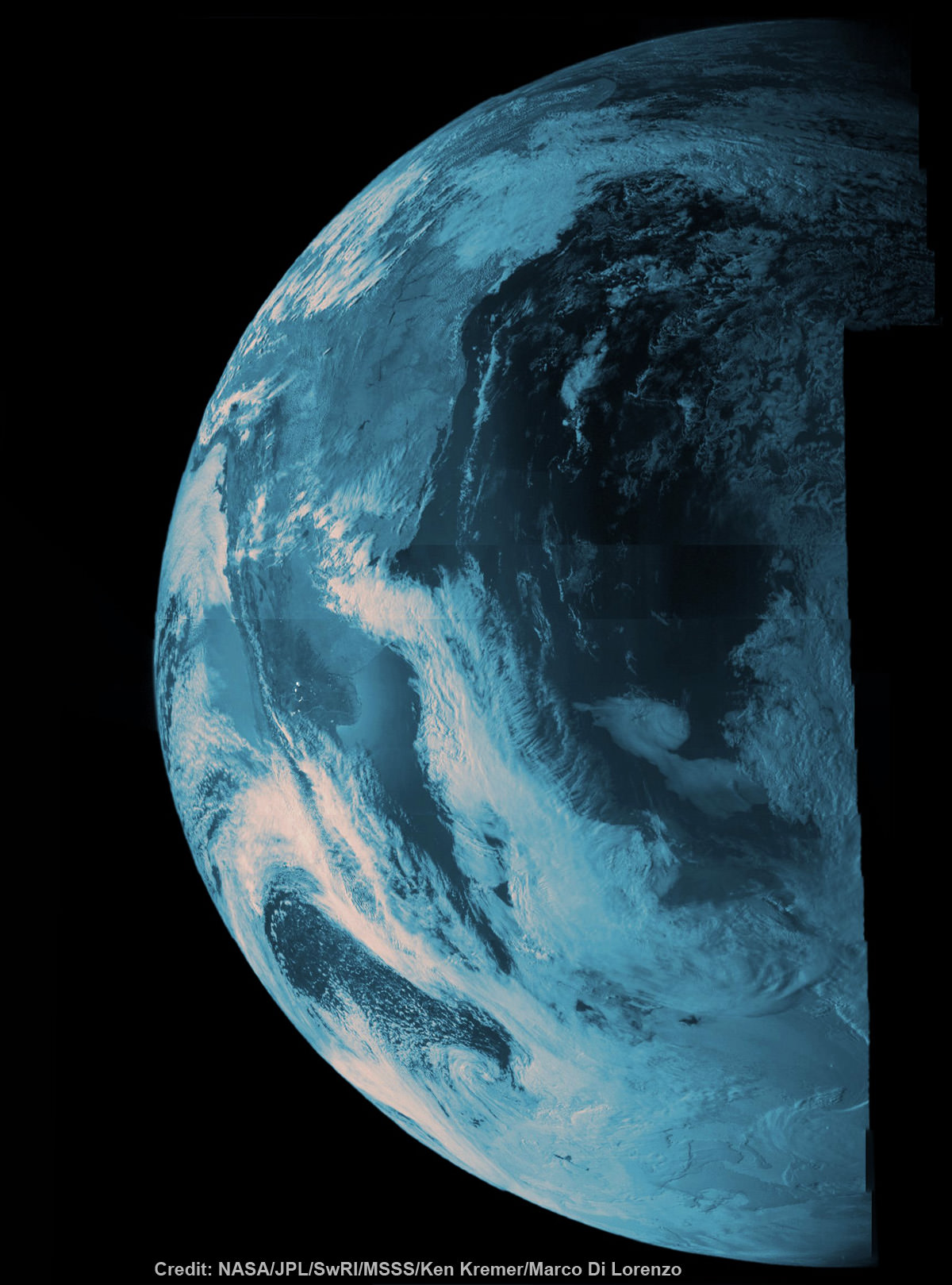

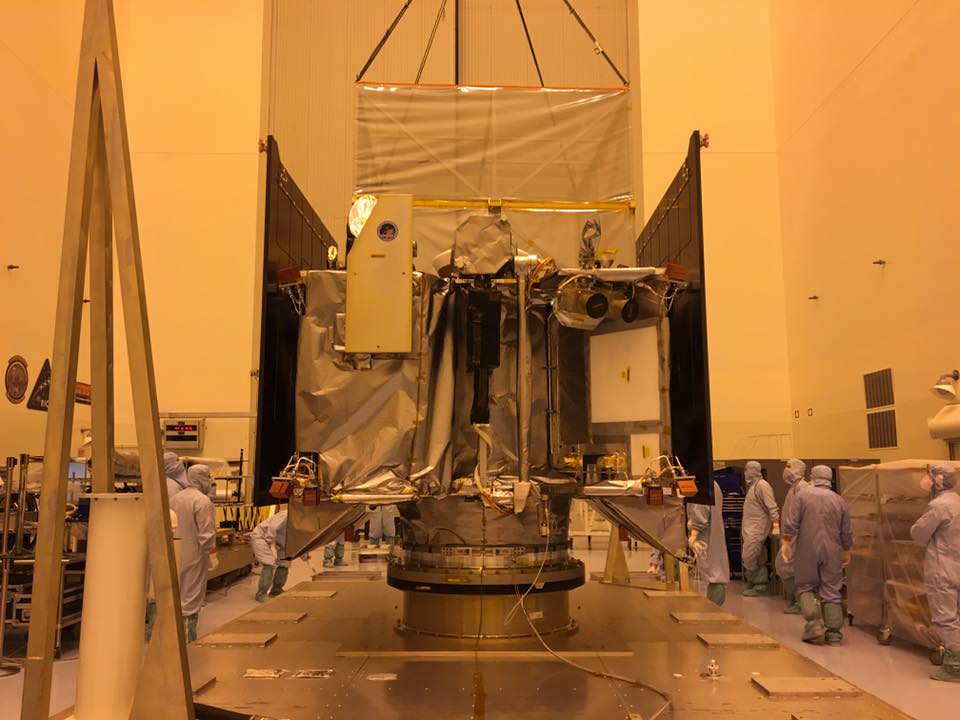

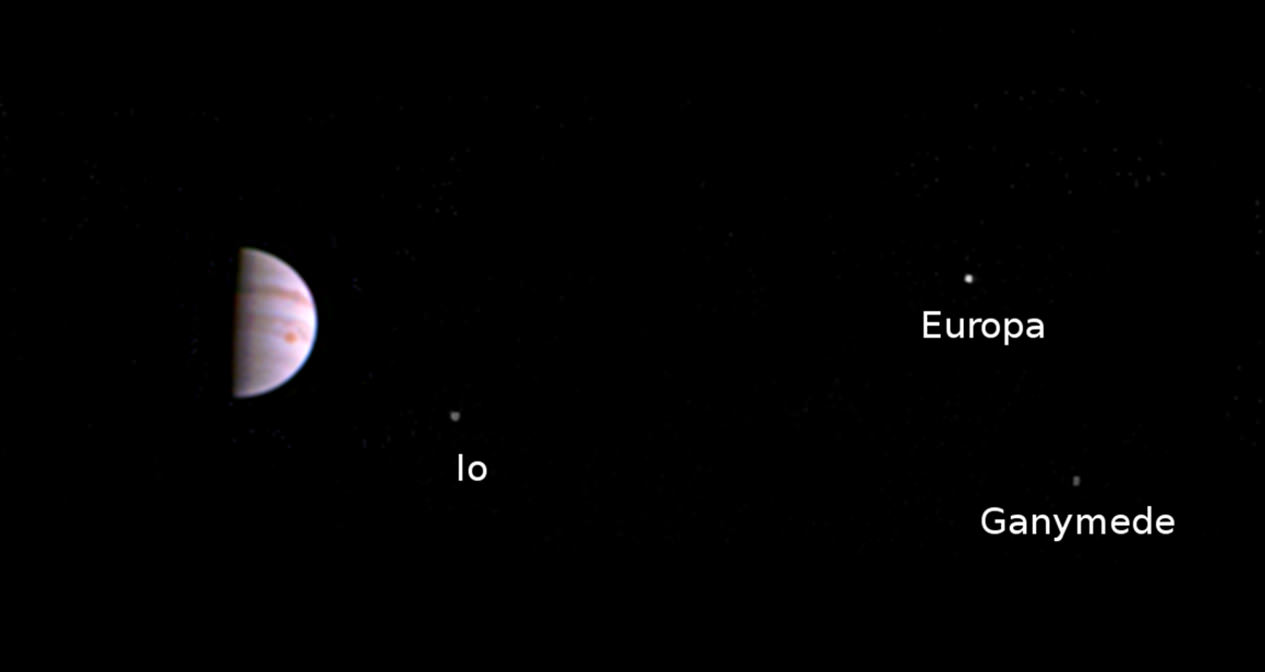

NASA’s newly arrived Jovian orbiter Juno has transmitted its first imagery since reaching orbit last week on July 4 after swooping over Jupiter’s cloud tops and powering back up its package of state-of-the-art science instruments for unprecedented research into determining the origin of our solar systems biggest planet.

The breathtaking image clearly shows the well known banded cloud tops in Jupiter’s atmosphere as well as the famous Great Red Spot and three of the humongous planet’s four largest moons — Io, Europa and Ganymede.

The ‘Galilean’ moons are annotated from left to right in the lead image.

Juno’s visible-light camera named JunoCam was turned on six days after Juno fired its main engine to slow down and be captured into orbit around Jupiter – the ‘King of the Planets’ following a nearly five year long interplanetary voyage from Earth.

The image was taken when Juno was 2.7 million miles (4.3 million kilometers) distant from Jupiter on July 10, at 10:30 a.m. PDT (1:30 p.m. EDT, 5:30 UTC), and traveling on the outbound leg of its initial 53.5-day capture orbit.

Juno came within only about 3000 miles of the cloud tops and passed through Jupiter’s extremely intense and hazardous radiation belts during orbital arrival over the north pole.

The newly released JunoCam image is visible proof that Juno survived the do-or-die orbital fireworks on America’s Independence Day that placed the baskeball-court sized probe into orbit around Jupiter – and is in excellent health to carry out its groundbreaking mission to elucidate Jupiter’s ‘Genesis.’

“This scene from JunoCam indicates it survived its first pass through Jupiter’s extreme radiation environment without any degradation and is ready to take on Jupiter,” said Scott Bolton, principal investigator from the Southwest Research Institute in San Antonio, in a statement.

“We can’t wait to see the first view of Jupiter’s poles.”

Within two days of the nerve wracking and fully automated 35-minute-long Jupiter Orbital Insertion (JOI) maneuver, the Juno engineering team begun powering up five of the probes science instruments on July 6.

All nonessential instruments and systems had been powered down in the final days of Juno’s approach to Jupiter to ensure the maximum chances for success of the critical JOI engine firing.

“We had to turn all our beautiful instruments off to help ensure a successful Jupiter orbit insertion on July 4,” said Bolton.

“But next time around we will have our eyes and ears open. You can expect us to release some information about our findings around September 1.”

Juno resumed high data rate communications with Earth on July 5, the day after achieving orbit.

We can expect to see more JunoCam images taken during this first orbital path around the massive planet.

But the first high resolution images are still weeks away and will not be available until late August on the inbound leg when the spacecraft returns and swoops barely above the clouds.

“JunoCam will continue to take images as we go around in this first orbit,” said Candy Hansen, Juno co-investigator from the Planetary Science Institute, Tucson, Arizona, in a statement.

“The first high-resolution images of the planet will be taken on August 27 when Juno makes its next close pass to Jupiter.”

All of JunoCams images will be released to the public.

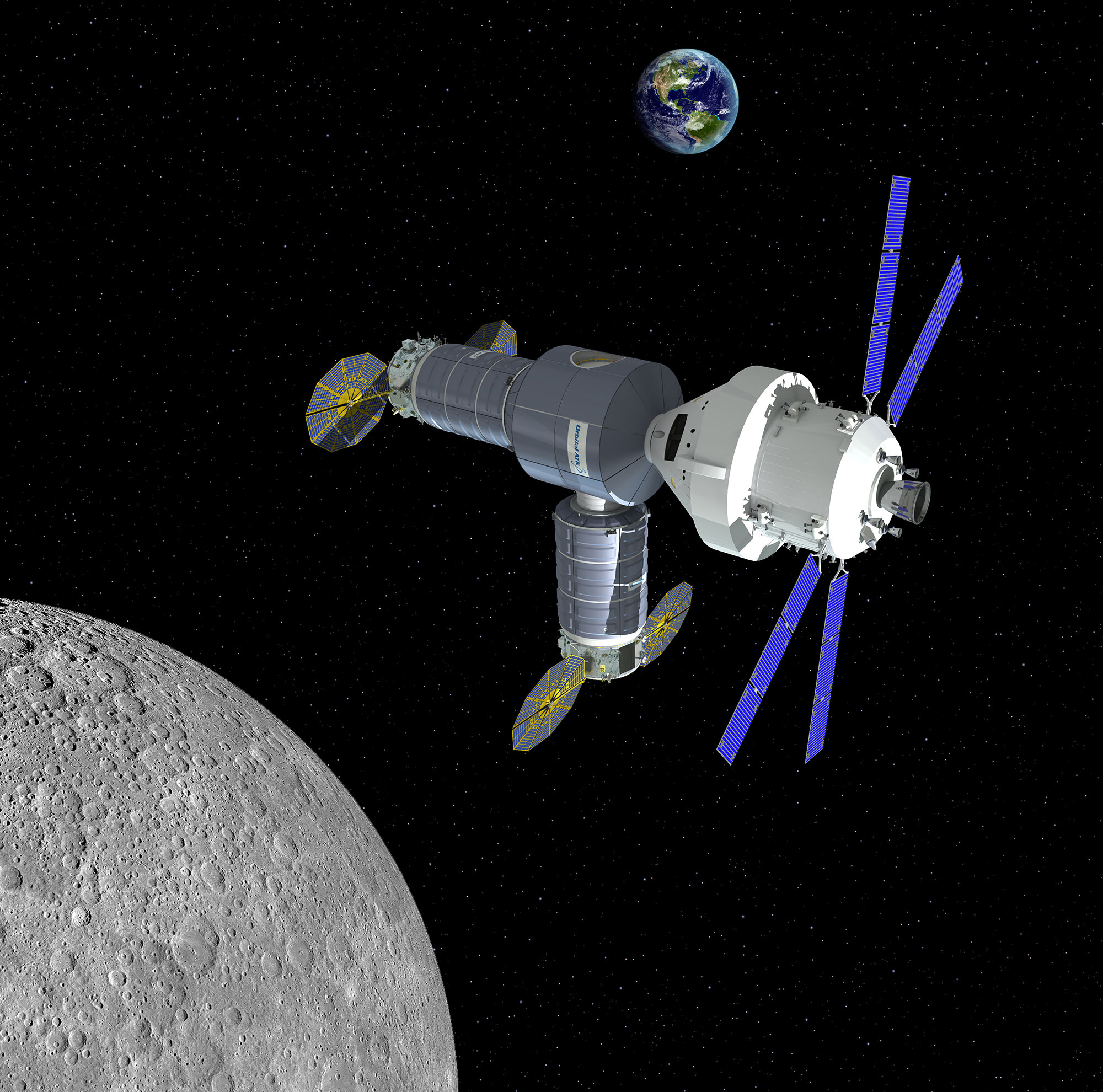

During a 20 month long science mission – entailing 37 orbits lasting 14 days each – the probe will plunge to within about 2,600 miles (4,100 kilometers) of the turbulent cloud tops.

It will collect unparalleled new data that will unveil the hidden inner secrets of Jupiter’s origin and evolution as it peers “beneath the obscuring cloud cover of Jupiter and study its auroras to learn more about the planet’s origins, structure, atmosphere and magnetosphere.”

The solar powered Juno spacecraft approached Jupiter over its north pole, affording an unprecedented perspective on the Jovian system – “which looks like a mini solar system” – as it flew through the giant planets intense radiation belts in ‘autopilot’ mode.

Juno is the first solar powered probe to explore Jupiter or any outer planet.

In the final weeks of the approach JunoCam captured dramatic views of Jupiter and all four of the Galilean Moons moons — Io, Europa, Ganymede and Callisto.

At the post JOI briefing on July 5, these were combined into a spectacular JunoCam time-lapse movie released by Bolton and NASA.

Watch and be mesmerized -“for humanity, our first real glimpse of celestial harmonic motion” says Bolton.

Video caption: NASA’s Juno spacecraft captured a unique time-lapse movie of the Galilean satellites in motion about Jupiter. The movie begins on June 12th with Juno 10 million miles from Jupiter, and ends on June 29th, 3 million miles distant. The innermost moon is volcanic Io; next in line is the ice-crusted ocean world Europa, followed by massive Ganymede, and finally, heavily cratered Callisto. Galileo observed these moons to change position with respect to Jupiter over the course of a few nights. From this observation he realized that the moons were orbiting mighty Jupiter, a truth that forever changed humanity’s understanding of our place in the cosmos. Earth was not the center of the Universe. For the first time in history, we look upon these moons as they orbit Jupiter and share in Galileo’s revelation. This is the motion of nature’s harmony. Credits: NASA/JPL-Caltech/MSSS

The $1.1 Billion Juno was launched on Aug. 5, 2011 from Cape Canaveral, Florida atop the most powerful version of the Atlas V rocket augmented by 5 solid rocket boosters and built by United Launch Alliance (ULA). That same Atlas V 551 version just launched MUOS-5 for the US Navy on June 24.

The Juno spacecraft was built by prime contractor Lockheed Martin in Denver.

The mission will end in February 2018 with an intentional death dive into the atmosphere to prevent any possibility of a collision with Europa, one of Jupiter’s moons that is a potential abode for life.

The last NASA spacecraft to orbit Jupiter was Galileo in 1995. It explored the Jovian system until 2003.

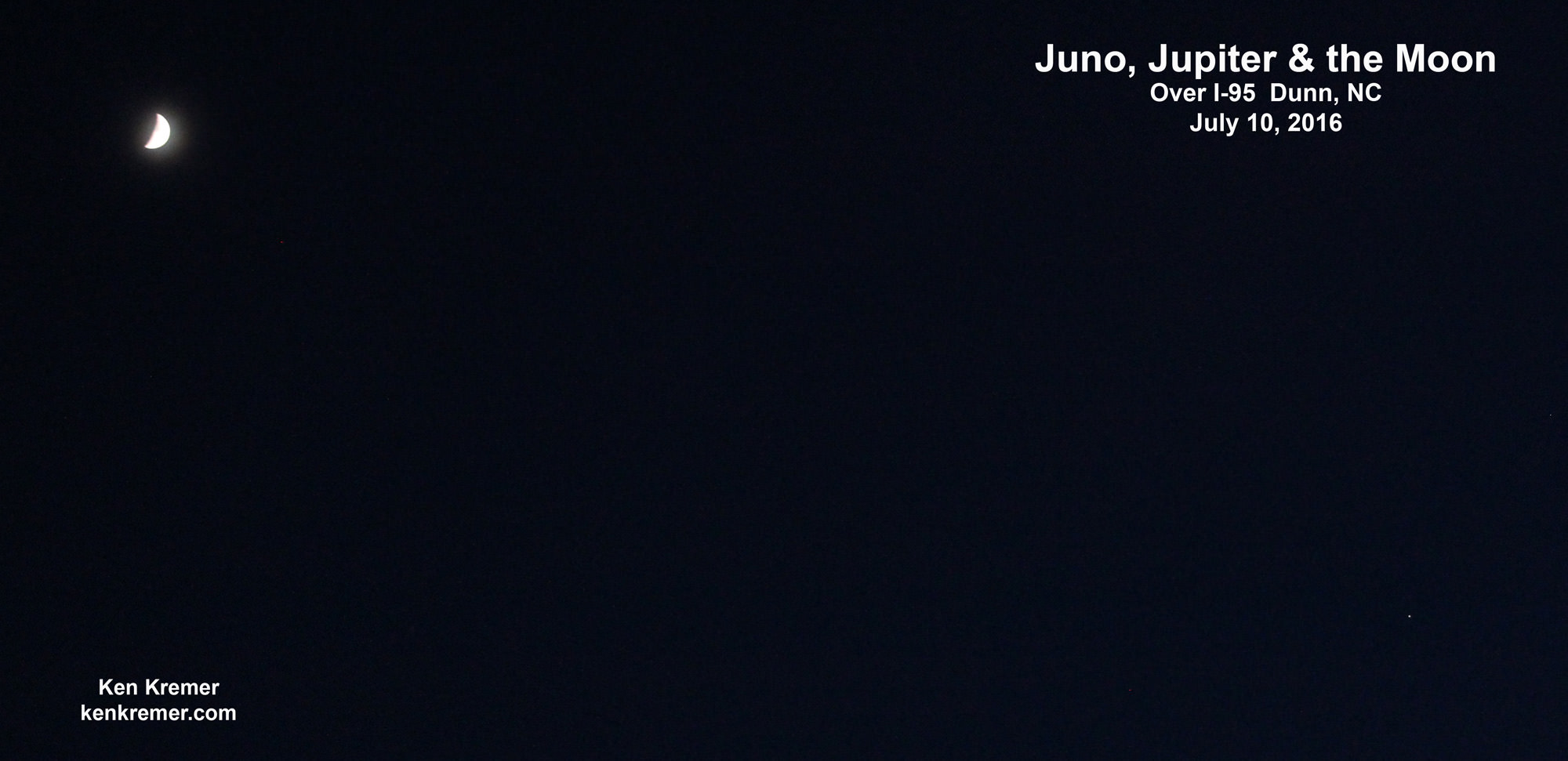

From Earth’s perspective, Jupiter was in conjunction with Earth’s Moon shortly after JOI during the first week in July.

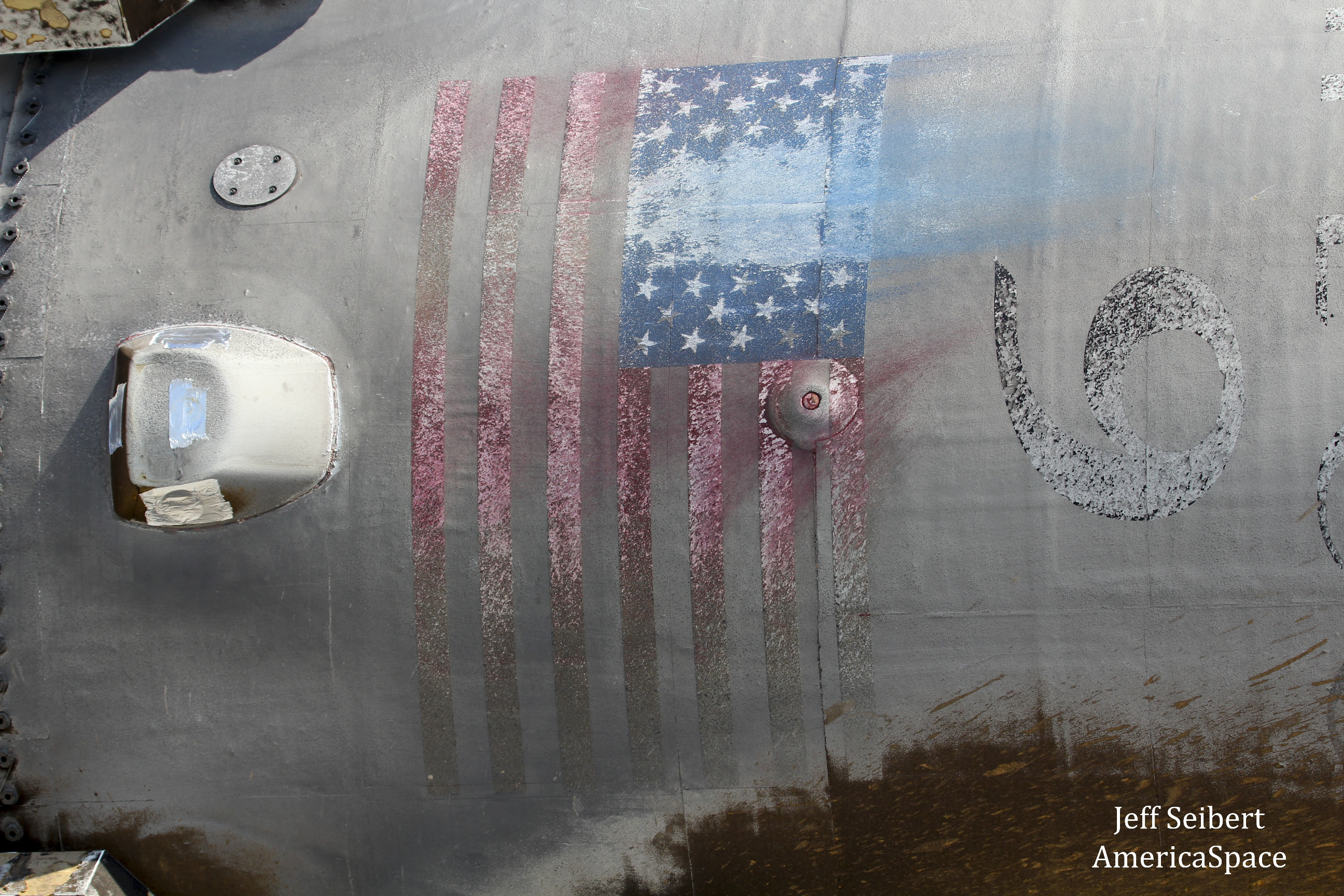

Personally its thrilling to realize that an emissary from Earth is once again orbiting Jupiter after a 13 year long hiatus as seen in the authors image below – coincidentally taken the same day as JunoCam’s first image from orbit.

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news.

………….

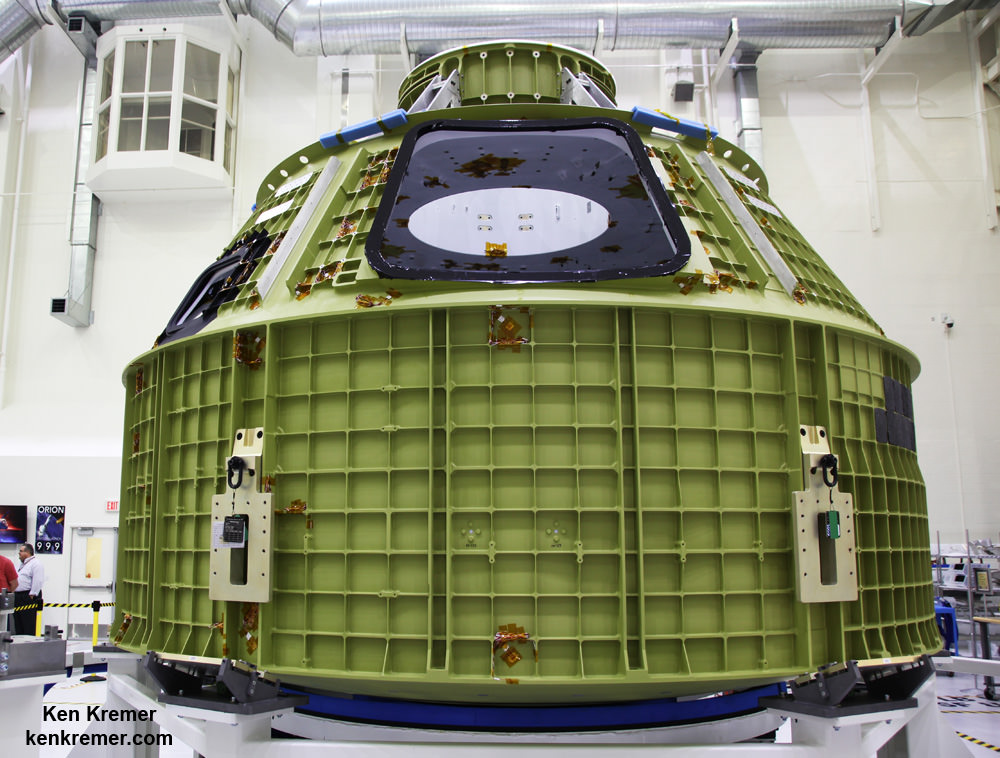

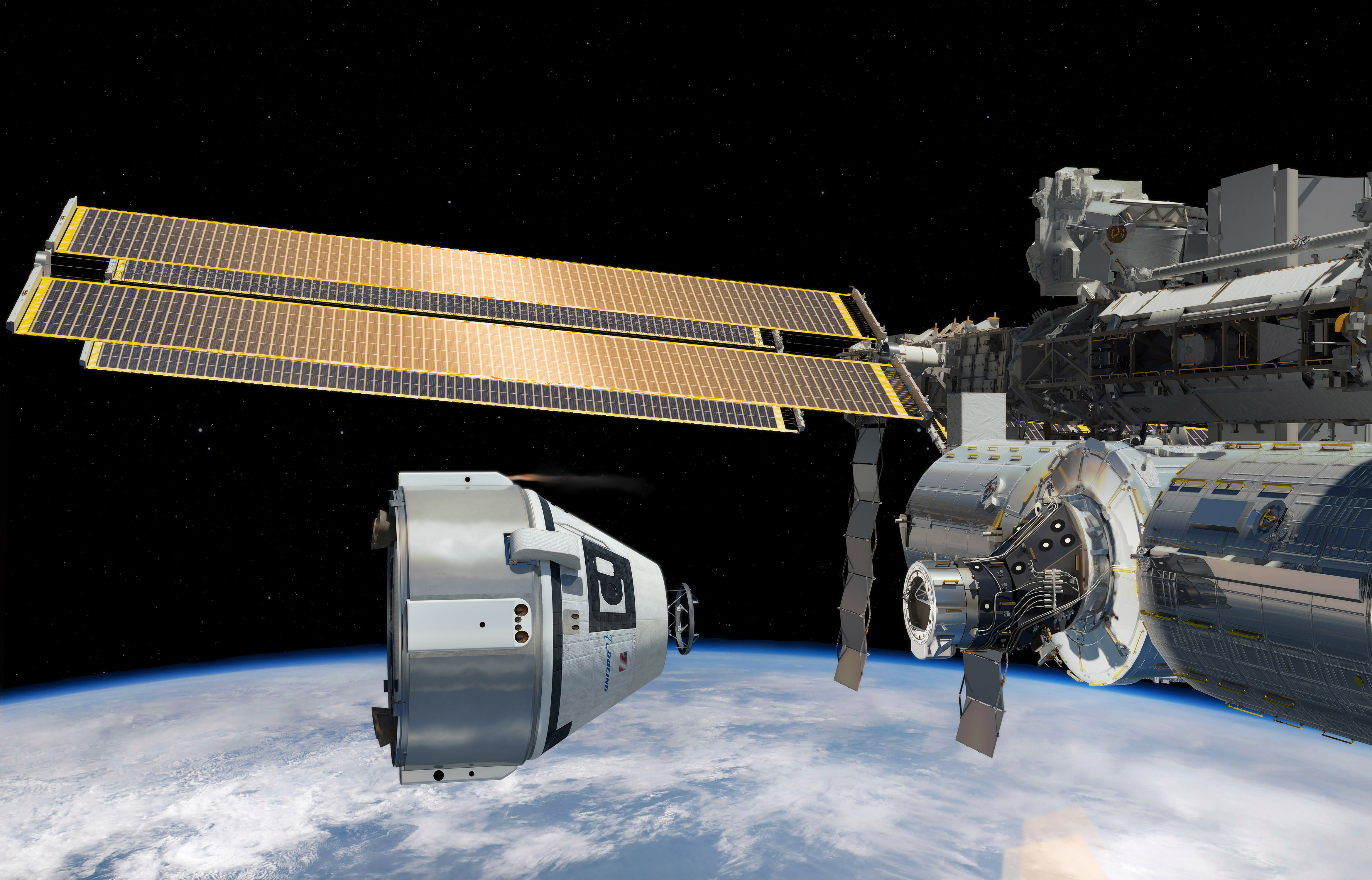

Learn more about Juno at Jupiter, SpaceX CRS-9 rocket launch, ISS, ULA Atlas and Delta rockets, Orbital ATK Cygnus, Boeing, Space Taxis, Mars rovers, Orion, SLS, Antares, NASA missions and more at Ken’s upcoming outreach events:

July 15-18: “SpaceX launches to ISS on CRS-9, Juno at Jupiter, ULA Delta 4 Heavy spy satellite, SLS, Orion, Commercial crew, Curiosity explores Mars, Pluto and more,” Kennedy Space Center Quality Inn, Titusville, FL, evenings