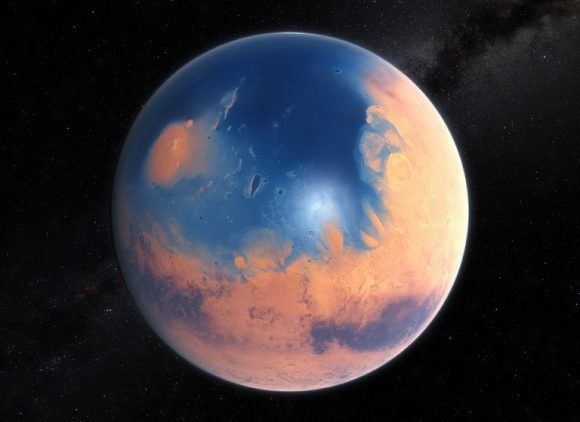

Martian dust storms are a pretty common occurrence, and generally happen whenever the southern hemisphere is experiencing summer. Though they can begin quite suddenly, these storms typically stay contained to a local area and last only about a few weeks. However, on occasion, Martian dust storms can grow to become global phenomena, covering the entire planet.

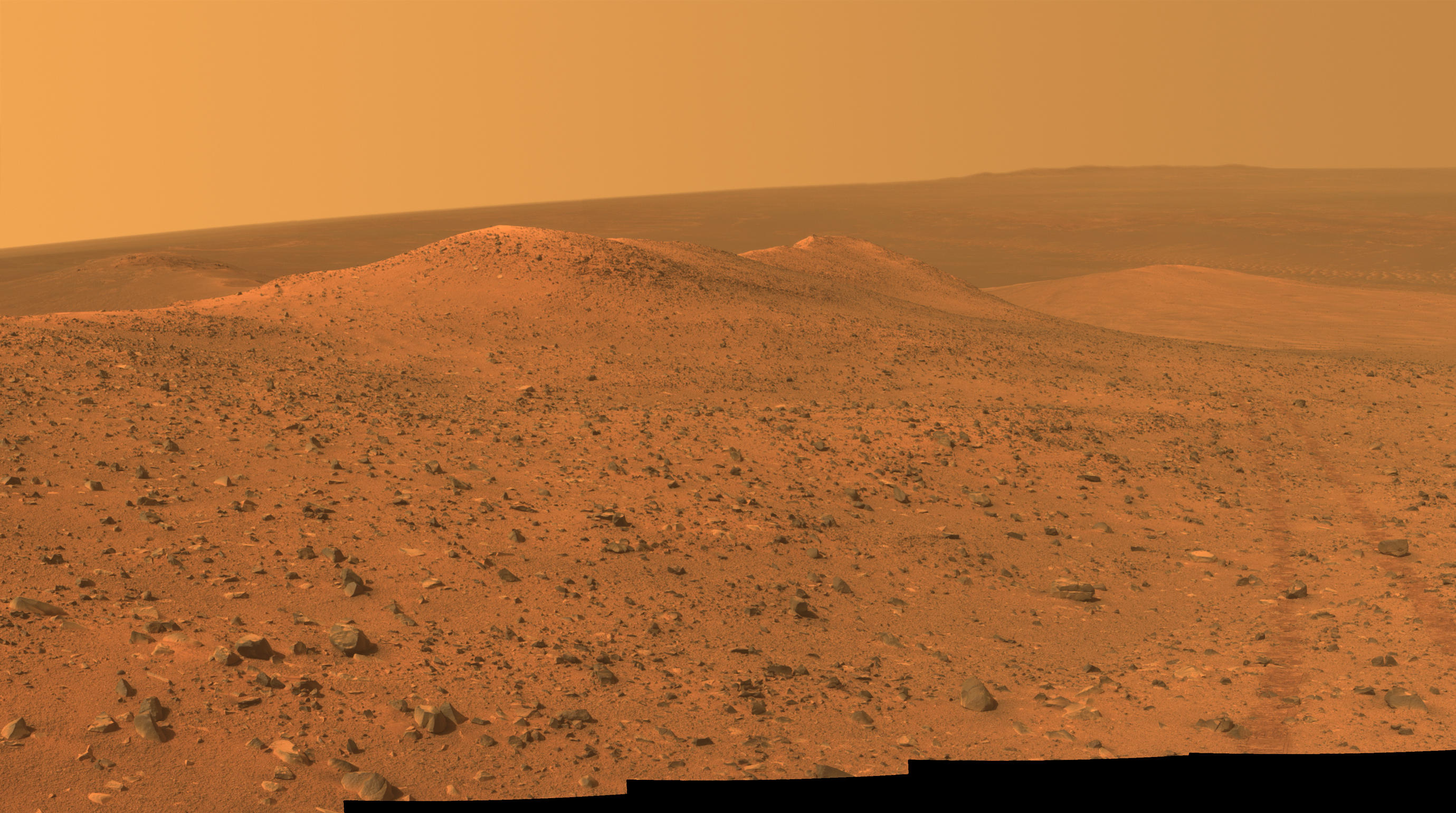

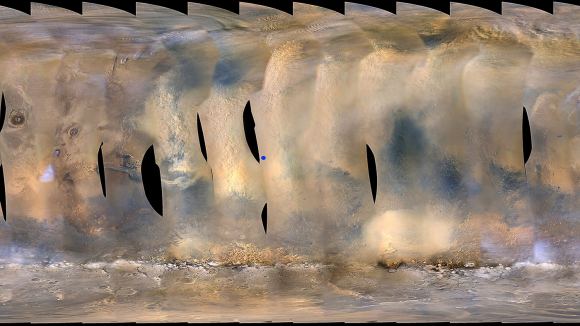

One such storm began back in May, starting in the Arabia Terra region and then spreading to become a planet-wide dust storm within a matter of weeks. This storm caused the skies over the Perseverance Valley, where the Opportunity rover is stationed, to become darkened, forcing the rover into hibernation mode. And while no word has been heard from the rover, NASA recently indicated that the dust storm will dissipate in a matter of weeks.

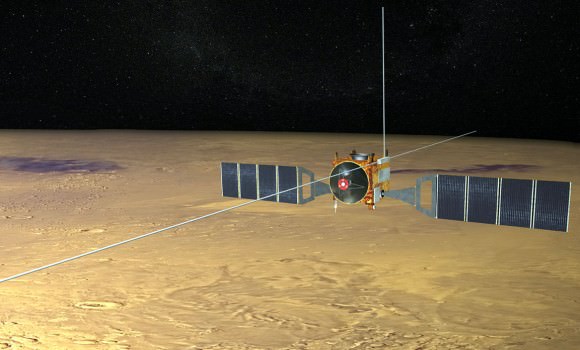

The update was posted by NASA’s Mars Exploration Program, which oversees operations for the Opportunity and Curiosity rovers, as well as NASA’s three Mars orbiters (Mars Odyssey, MRO, and MAVEN) and the Insight lander (which will land on Mars in 109 days). According to NASA, the storm is beginning to end, though it may be weeks or months before the skies are clear enough for Opportunity to exit its hibernation mode.

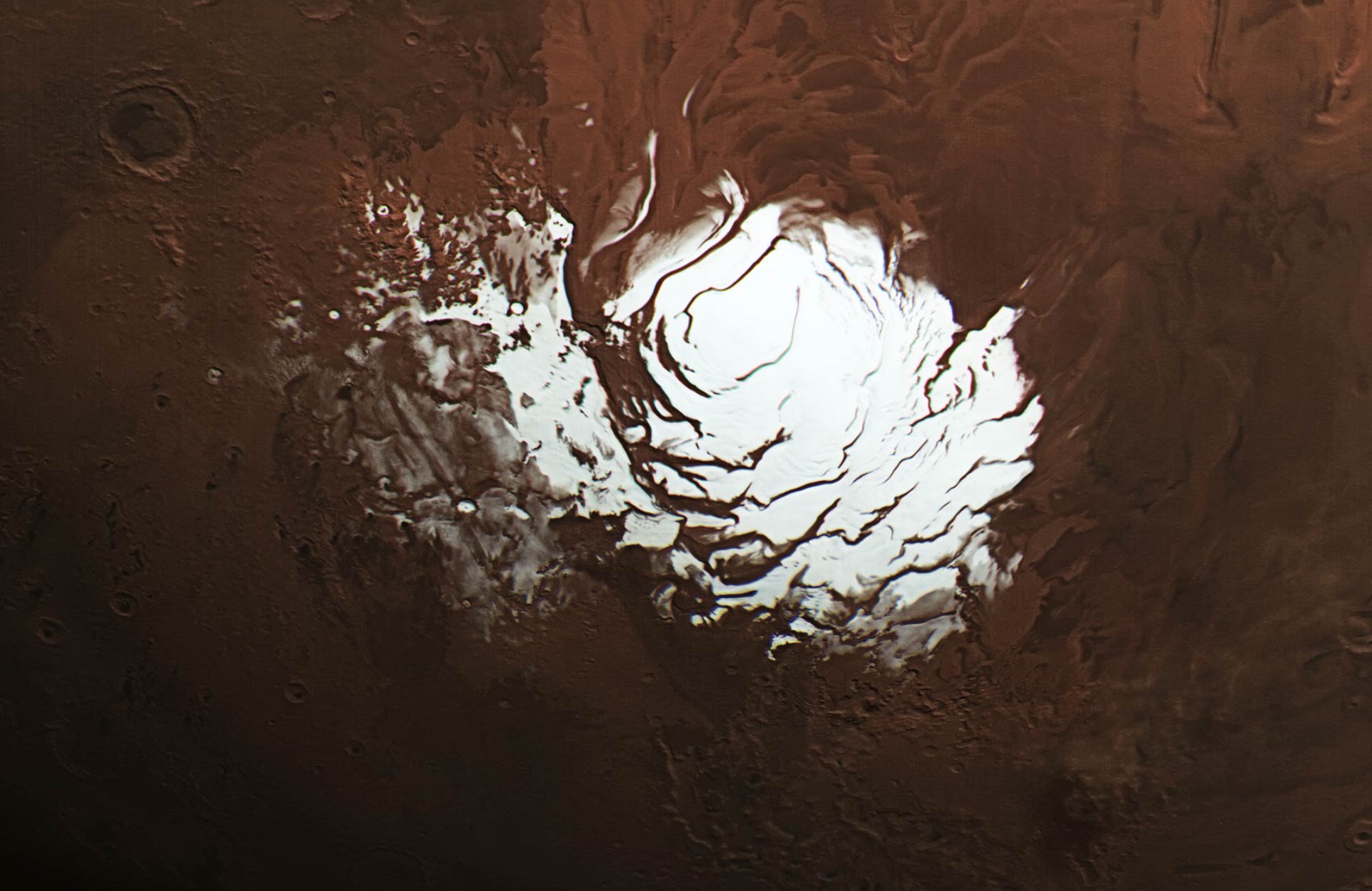

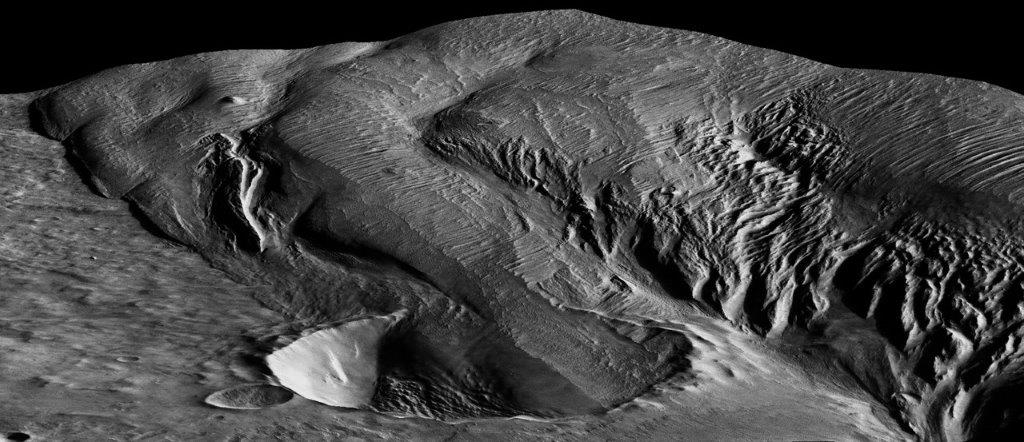

As noted, dust storms occur on Mars when the southern hemisphere experiences summer, which coincides with the planet being closer to the Sun in its elliptical orbit. Due to increased temperatures, dust particles are lifted higher into the atmosphere, creating more wind. The resulting wind kicks up yet more dust, creating a feedback loop that NASA scientists are still trying to understand.

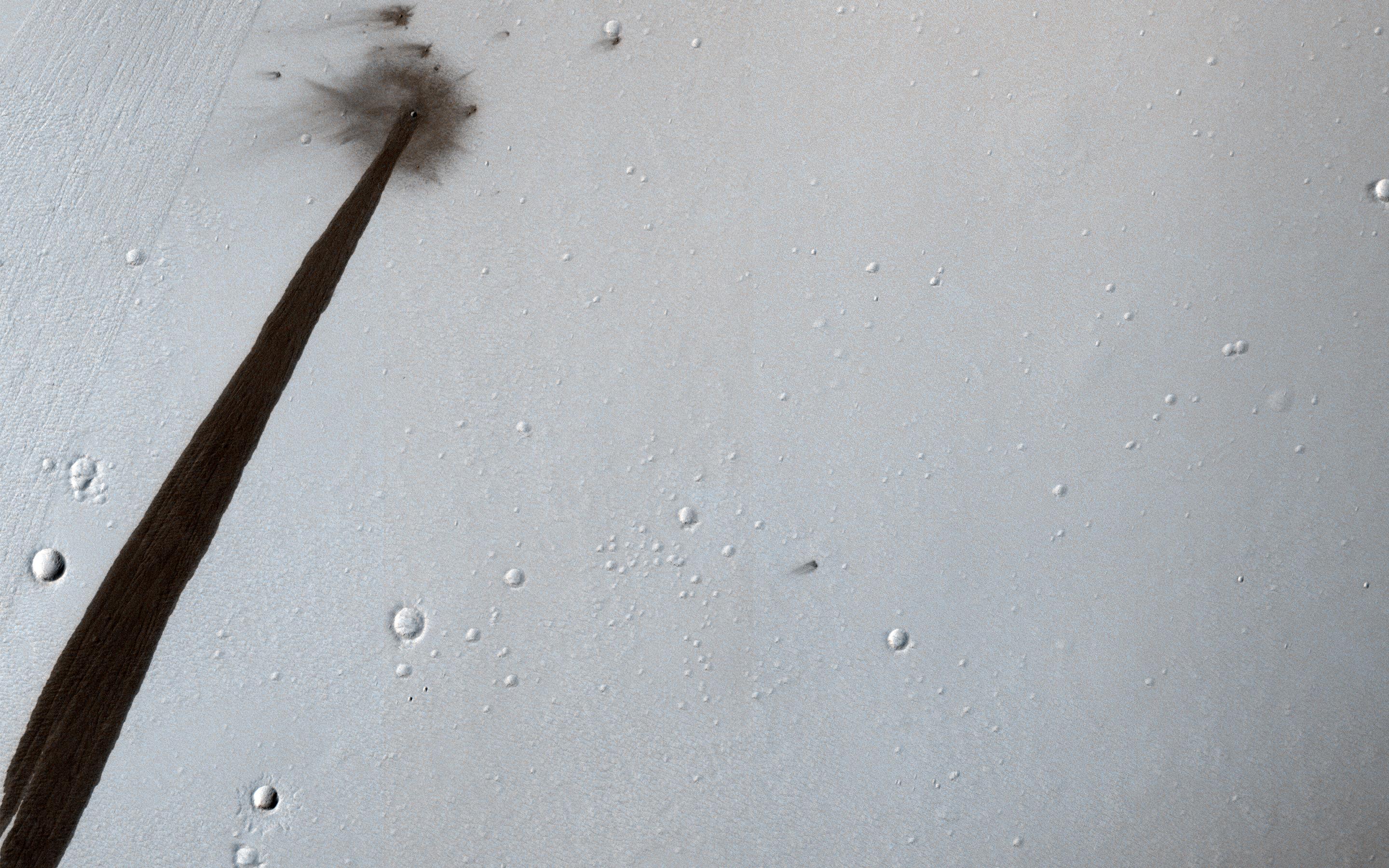

Since the southern polar region is pointed towards the Sun in the summer, carbon dioxide frozen in the polar cap evaporates. This has the effect of thickening the atmosphere and increasing the surface pressure, which enhances the process by helping suspend dust particles in the air. In some cases, the dust clouds can reach up to 60 km (40 mi) or more in elevation.

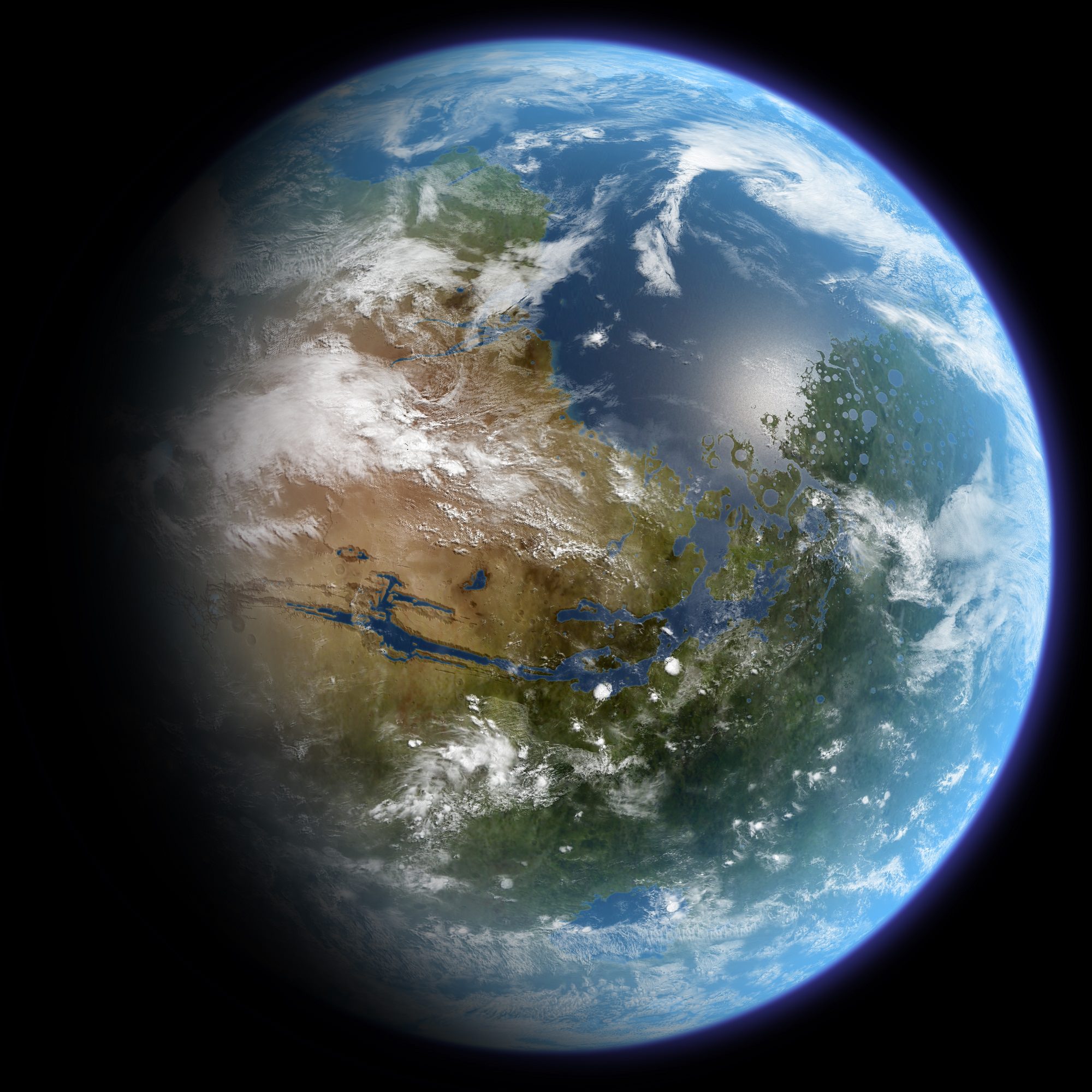

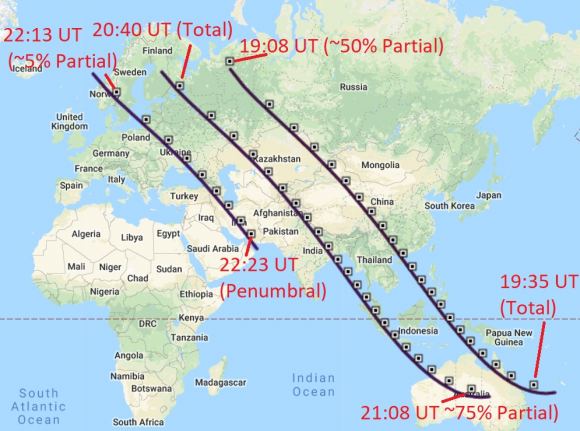

Planet-wide dust storms are a relatively rare occurrence on Mars, taking place every three to four Martian years (the equivalent of approximately 6 to 8 Earth years). Such storms have been viewed many times in the past by missions like Mariner 9 (1971), Viking I (1971) and the Mars Global Surveyor (2001). In 2007, a similar storm took place that darkened the skies over where Opportunity was stationed – which led to two weeks of minimal operations and no communications.

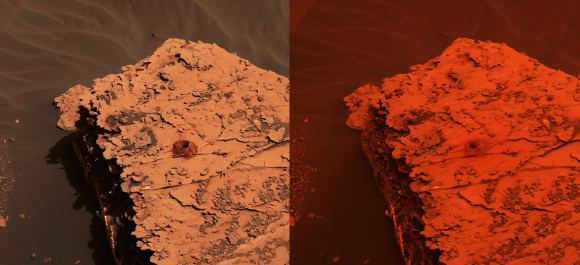

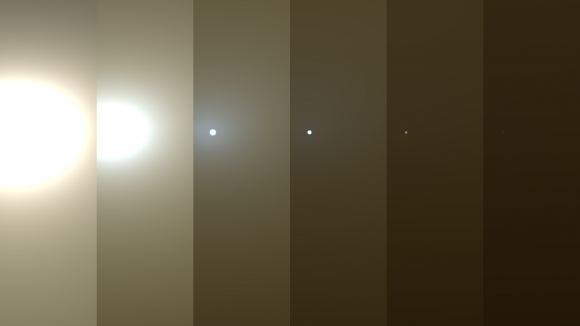

While smaller and less intense the storm that took place back in 2007, the current storm intensified to the point where it led to a level of atmospheric opacity that is much worse than the 2007 storm. In effect, the amount of dust in the atmosphere created a state of perpetual night over the rover’s location in Perseverance Valley, which forced the rover’s science team to suspend operations.

This is due to the fact that Opportunity – unlike the Curiosity rover, which runs on nuclear-powered battery – relies on solar panels to keep its batteries charged. But beyond suspending operations, the prolonged dust storm also means that the rover might not be to keep its energy-intensive survival heaters running – which protect its batteries from the extreme cold of Mars’ atmosphere.

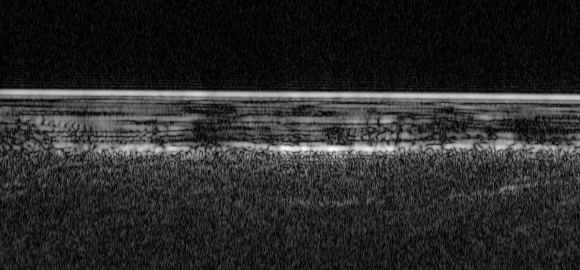

Luckily, NASA scientists who have been observing the global event indicated that, as of last Monday (July 23rd), more dust was falling out of the planet’s thin air than was being raised into it. This means that the global weather event has reached its decay phase, where dust-raising events either become confined to smaller areas or stop altogether.

Using its Mars Color Imager (MARCI) and Mars Climate Sounder (MCS), NASA’s Mars Reconnaissance Orbiter (MRO) also noted surface features were beginning to reappear and that temperatures in the middle atmosphere were no longer rising – which indicates less solar heating by dust. The Curiosity rover also noted a decline in dust above its position in the Gale Crater on the other side of the planet.

This is certainly good new for the Opportunity rover, though scientists expect that it will still be a few weeks or months before its solar panels can draw power again and communications can be reestablished. The last time communications took place with the rover was on June 10th, but if there’s one thing the Opportunity rover is known for, it’s endurance!

When the rover first landed on Mars on January 25th, 2004, its mission was only expected to last ninety Martian days (sols), which is the equivalent of about 92.5 Earth days. However, as of the writing of this article, the rover has endured for 14 years and 195 days, effectively exceeding its operational lifespan 55 times over. So if any rover can survive this enduring dust storm, its Opportunity!

In the meantime, multiple NASA missions are actively monitoring the storm in support of Opportunity and to learn more about the mechanics of Martian storms. By learning more about what causes these storms, and how smaller ones can merge to form global events, future robotic missions, crewed missions and (quite possibly) Martian colonists will be better prepared to deal with them.

Further Reading: NASA