After months of discussion, the space agencies behind the Lunar Gateway have decided how the space station will orbit the Moon. NASA and the ESA are developing the Lunar Gateway jointly, and the orbital path that it will follow around the Moon is a key part of mission design. It’ll affect all the vital aspects of the mission, including how spacecraft will rendezvous and land at the station.

Continue reading “The Lunar Gateway Will be in a “Near-Rectilinear Halo Orbit””LightSail 2 is Sending Home New Pictures of Earth

LightSail 2, the brainchild of The Planetary Society, has gifted us two new gorgeous images of Earth. The small spacecraft is currently in orbit at about 720 km, and the LightSail 2 mission team is putting it through its paces in preparation for solar sail deployment sometime on or after Sunday, July 21st.

Continue reading “LightSail 2 is Sending Home New Pictures of Earth”The ESA’s SpaceBok Robot Will Hop Its Way Around Low-Gravity Worlds

The ESA is helping a group of students from Zurich test and develop their hopping exploration robot. Called SpaceBok, the robot is designed to operate on low-gravity bodies like the Moon or asteroids. It’s based on the concept of ‘dynamic walking’, something that animals on Earth use.

Continue reading “The ESA’s SpaceBok Robot Will Hop Its Way Around Low-Gravity Worlds”MOONRISE: Melting lunar regolith with lasers to build structures on the Moon

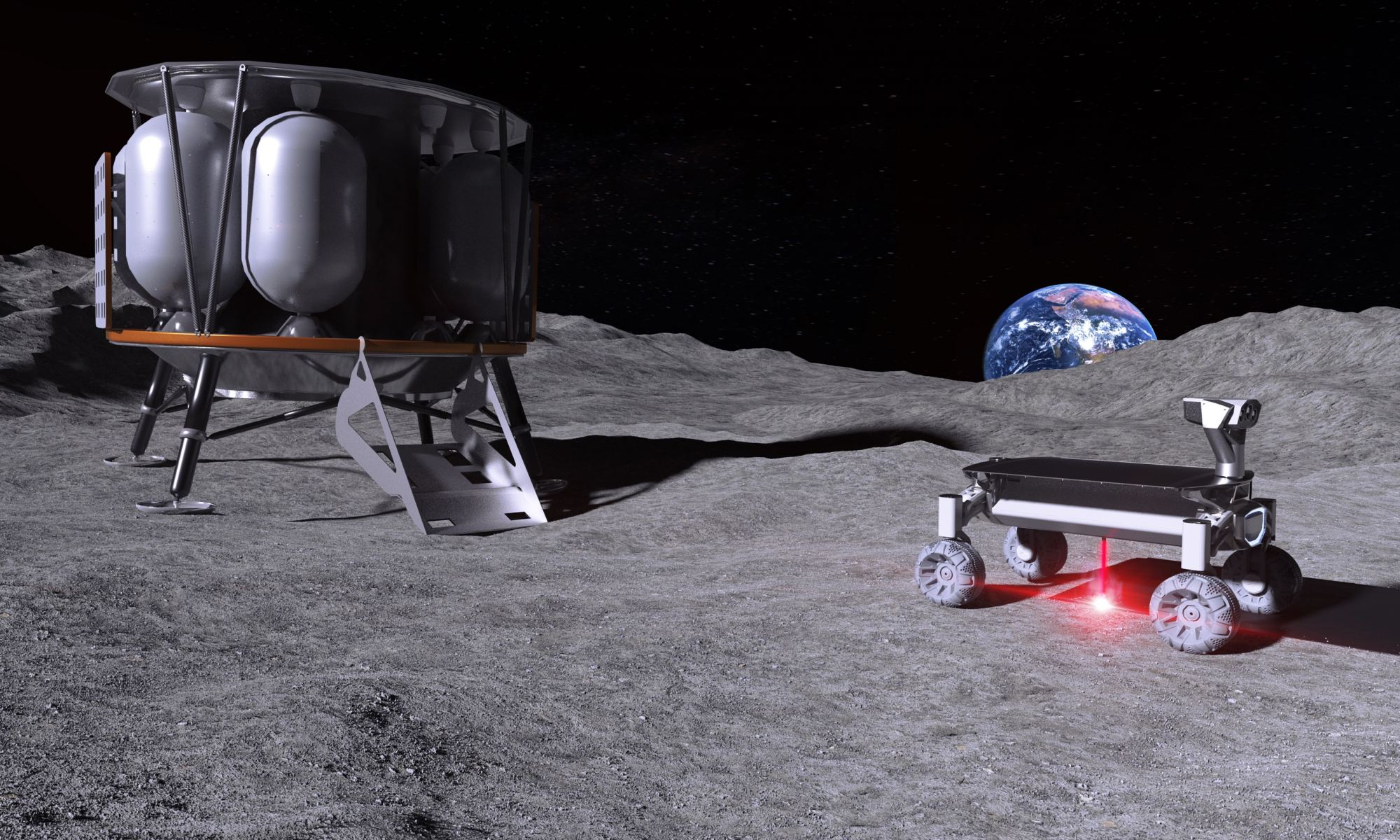

The Moon is not just Earth’s closest celestial neighbor. It’s also a natural waypoint for any mission that will be going to Mars or beyond in the coming years. It’s little wonder then why space agencies like NASA, Roscosmos, the ESA and China are hoping to send crewed missions there in the near future and construct bases that could be used to resupply and refuel missions headed to deep space.

So far, all the proposals made for a lunar base have centered on in-situ resource utilization (ISRU) and 3D printing – where robots will manufacture the base out of lunar regolith. For this purpose, the Laser Zentrum Hannover (LZH) and the Institute of Space Systems (IRAS) at the Technical University of Braunschweig came together to develop a laser system capable of turning moon dust into building materials.

Continue reading “MOONRISE: Melting lunar regolith with lasers to build structures on the Moon”Prototype of a Future Interstellar Probe was Just Tested on a Balloon

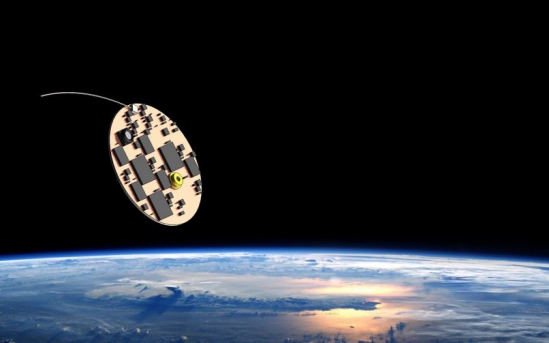

At the University of California, Santa Barbara, researchers with the UCSB Experimental Cosmology Group (ECG) are currently working on ways to achieve the dream of interstellar flight. Under the leadership of Professor Philip Lubin, the group has dedicated a considerable amount of effort towards the creation of an interstellar mission consisting of directed-energy light sail and a wafer-scale spacecraft (WSS) “wafercraft“.

If all goes well, this spacecraft will be able to reach relativistic speeds (a portion of the speed of light) and make it to the nearest star system (Proxima Centauri) within our lifetimes. Recently, the ECG achieved a major milestone by successfully testing a prototype version of their wafercraft (aka. the “StarChip“). This consisted of sending the prototype via balloon into the stratosphere to test its functionality and performance.

Continue reading “Prototype of a Future Interstellar Probe was Just Tested on a Balloon”SpaceX Tests the Starship’s Hexagonal Heatshield. Starhopper Tests Could Come as Early as This Week

The milestones just keep coming for SpaceX. After the recent successful test flight of the Crew Dragon capsule, another of SpaceX’s ventures is about to meet its own milestone. The SpaceX Starhopper could have its first test flight as soon as this week.

Continue reading “SpaceX Tests the Starship’s Hexagonal Heatshield. Starhopper Tests Could Come as Early as This Week”Steam-Powered Spacecraft Could Explore the Asteroid Belt Forever, Refueling Itself in Space

The era of renewed space exploration has led to some rather ambitious proposals. While many have been on the books for decades, it has only been in recent years that some of these plans have become technologically feasible. A good example is asteroid mining, where robotic spacecraft would travel to Near-Earth Asteroids and the Main Asteroid Belt to harvest minerals and other resources.

At the moment, one of the main challenges is how these craft would be able to get around and refuel once they are in space. To address this, the New York-based company Honeybee Robotics has teemed up with the University of Central Florida (UFC) to develop a steam-powered robotic spacecraft. The company recently released a demonstration video that shows their prototype World is Not Enough (WINE) “steam hopper” in action.

Continue reading “Steam-Powered Spacecraft Could Explore the Asteroid Belt Forever, Refueling Itself in Space”The Prototype for the Starship has been Assembled, Hop Tests Could be Happening Soon

In an announcement sure to make you quiver with delight, Elon Musk says that SpaceX could begin short-hop test flights of its Starship prototype as early as next Spring. The Starship, which looks like something from a 1950’s sci-fi novel cover (awesome!) is intended to carry people to the Moon and Mars. When the spacecraft design was originally announced in 2016, it was called the Mars Colonial Transporter, and it sent shockwaves through the community.

Now, it’s almost test-flight time.

Continue reading “The Prototype for the Starship has been Assembled, Hop Tests Could be Happening Soon”A Nuclear-Powered Tunneling Robot that Could Search for Life on Europa

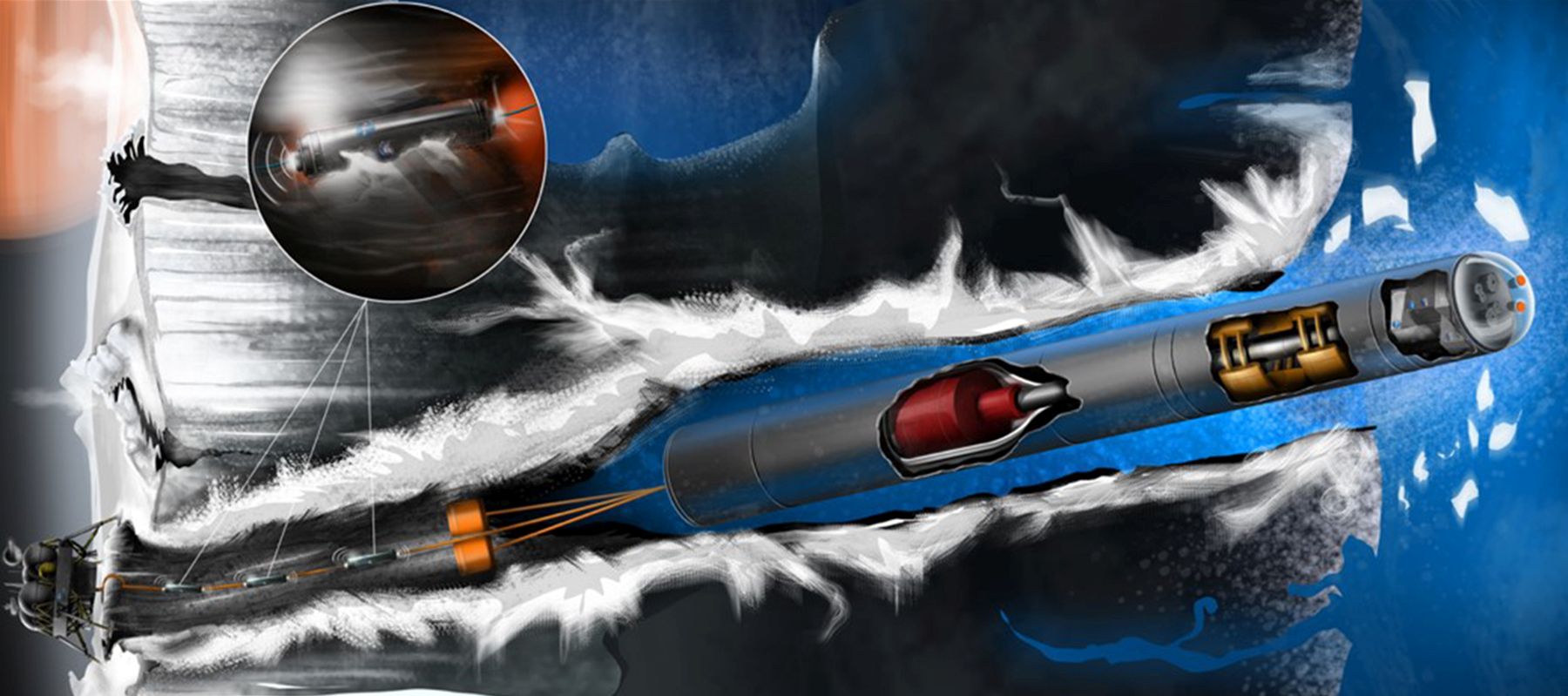

The search for life has led astronomers to the icy moons in our Solar System. Among those moons, Europa has attracted a lot of attention. Europa is Jupiter’s fourth-largest moon—and the sixth-largest in the Solar System—at 3,100 kilometres (1,900 mi) in diameter. Scientists think that its oceans could contain two or three times as much water as Earth’s oceans. The only problem is, that water is hidden under a sheet of planet-wide ice that could be between 2km and 30km (1.2 miles and 18.6 miles) thick.

A team of scientists is working hard on the problem. Andrew Dombard, associate professor of Earth and Environmental Sciences at the University of Illinois at Chicago, is part of a team that presented a possible solution. At the American Geophysical Union meeting in Washington, D.C., they presented their idea: a nuclear-powered tunneling robot that could tunnel its way through the ice and into the ocean.

Continue reading “A Nuclear-Powered Tunneling Robot that Could Search for Life on Europa”

Exactly How We Would Send our First Laser-Powered Probe to Alpha Centauri

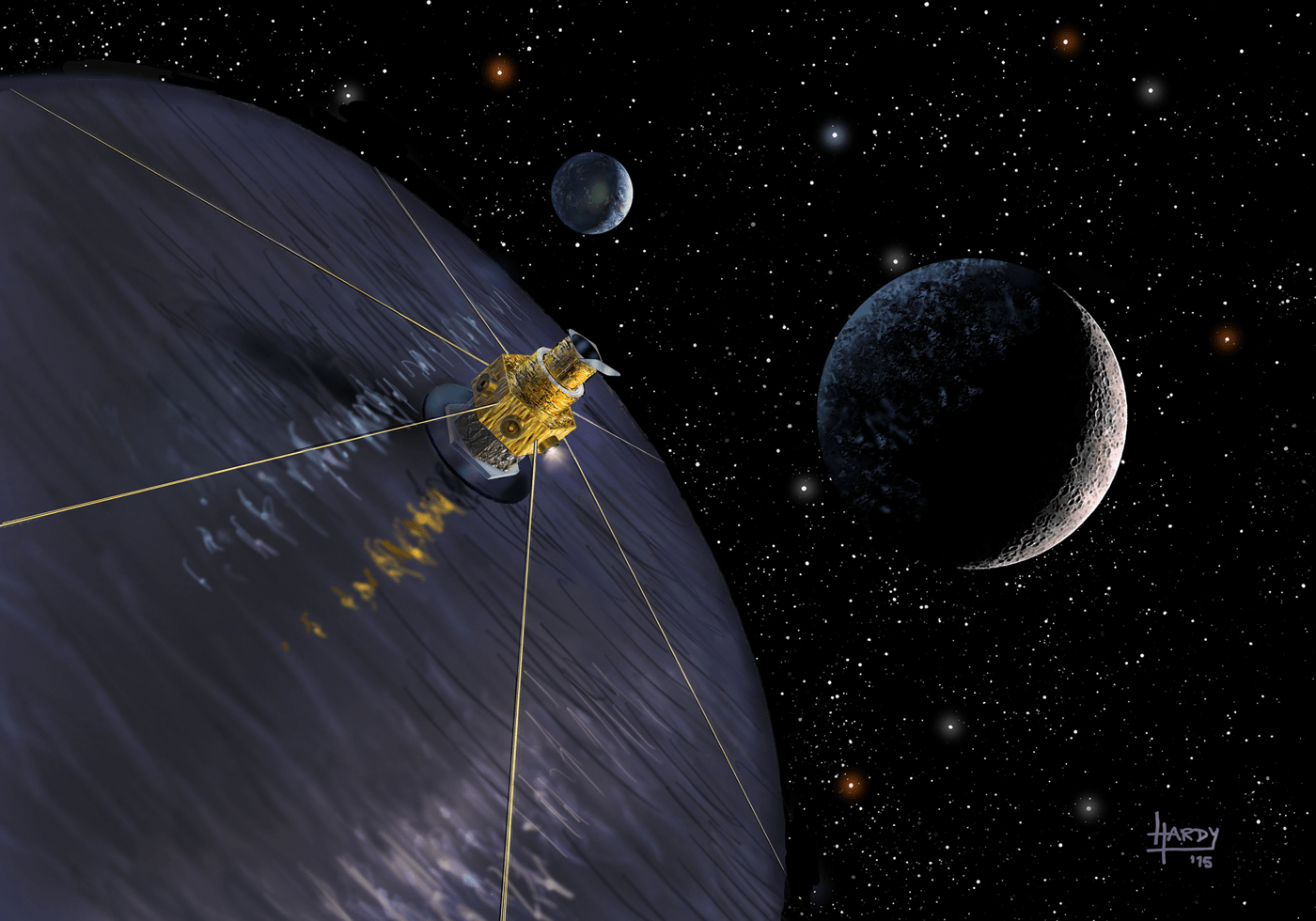

The dream of traveling to another star system, and maybe even finding populated worlds there, is one that has preoccupied humanity for many generations. But it was not until the era of space exploration that scientists have been able to investigate various methods for making an interstellar journey. While many theoretical designs have been proposed over the years, a lot of attention lately has been focused on laser-propelled interstellar probes.

The first conceptual design study, known as Project Dragonfly was hosted by the Initiative for Interstellar Studies (i4iS) in 2013. The concept called for the use of lasers to accelerate a light sail and spacecraft to 5% the speed of light, thus reaching Alpha Centauri in about a century. In a recent paper, one of the teams that took part in the design competition assessed the feasibility of their proposal for a lightsail and magnetic sail.

Continue reading “Exactly How We Would Send our First Laser-Powered Probe to Alpha Centauri”