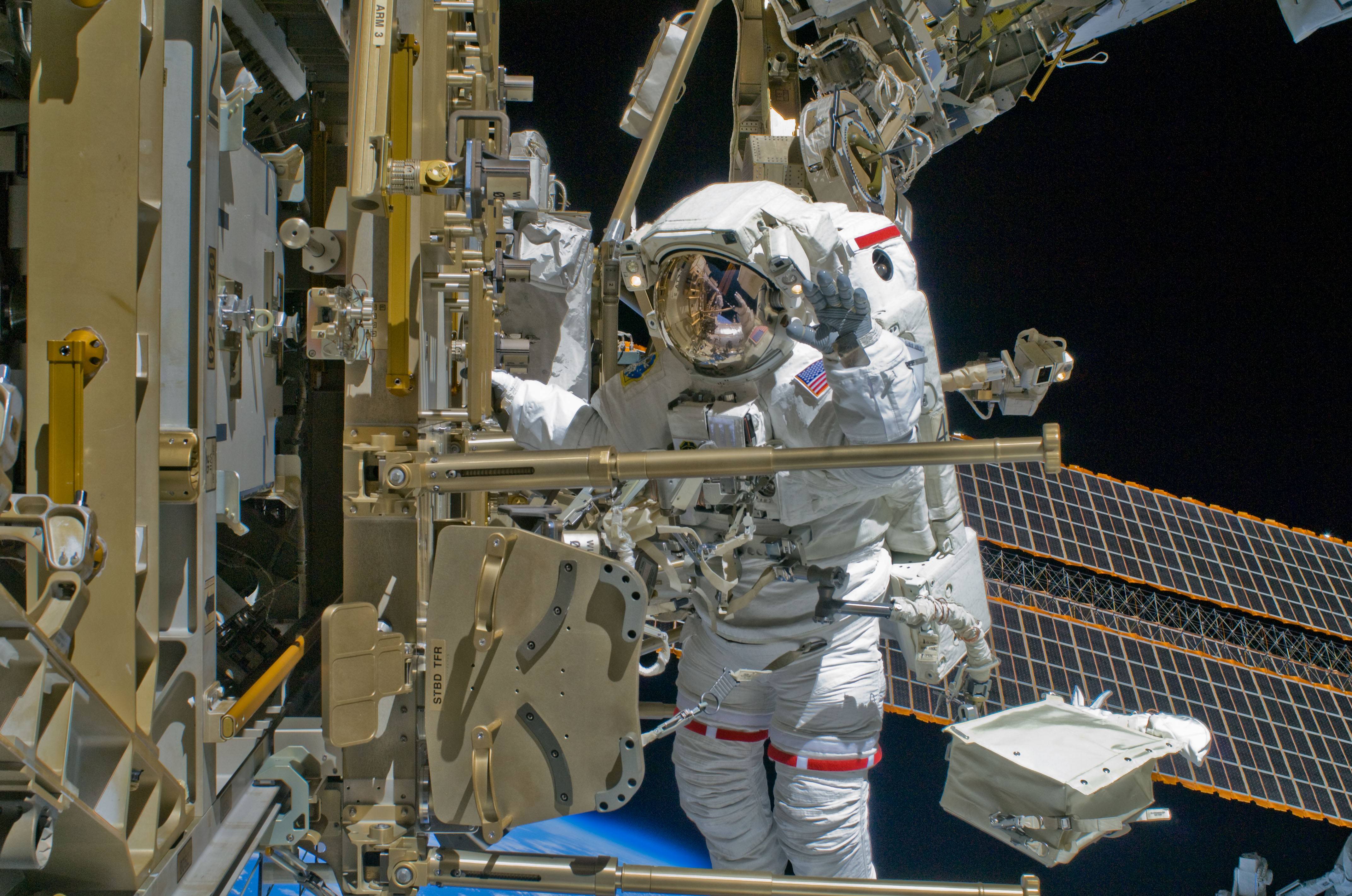

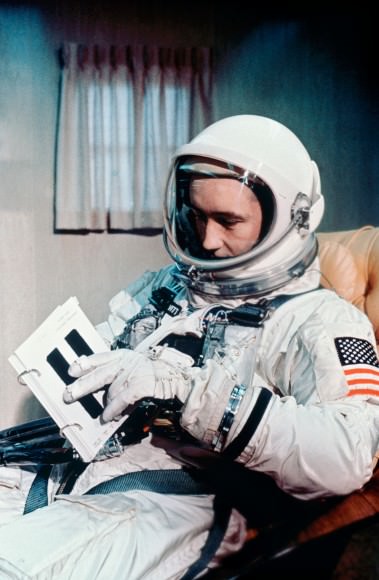

Reader Jeff Arnoldi recently approached me with an intriguing question about this Apollo 1 picture:

Note that the U.S. flag is on their right shoulders. Every other Apollo mission crew and all mission crews since then wear the flag on their left shoulders. Did the astronauts change after the Apollo 1 fire? Why did they make the change?

In response, Universe Today put a call out to several people with knowledge of those spacesuits that were used in the Apollo 1 mission, which ended fatally in January 1967 when all three crew members died in a pad fire.

A lot of redesigns were made to the equipment to prevent the same situation from happening again, but it appears the flags were not that crucial to the spacesuit design — even though a new spacesuit was used in Apollo 7.

Weeks of searching later, we have some great theories from the experts about why the flags were switched, but no definitive answer. Feel free to let us know if you have heard anything!

There’s some important historical context about the suit that we’ll get into in a moment, but first, here’s some feedback we received from a few spacesuit experts:

Walter Cunningham, Apollo 7 astronaut and backup crew member for Apollo 1:

Our crew, obviously, wore both. We were concerned about flexibility and security of the suits. We had no time to be concerned with style or decorations. I know of no policy decision on the question you asked.

Shawn McLeod, field operations manager for David Clark Co. (which constructed the suit):

Our archives indicate photos in the field of the Apollo A1-C suits both with and without the U.S. flag. Based on our literature search, our team believes positioning/placement of the U.S. flag was more than likely performed in the field after the suits were delivered from David Clark Company. Field installation of patches is not unusual – especially, for a program as fast-paced as Apollo. […]

Anecdotal evidence leads us to believe that the flags were sewn on whichever arm there was room. The left arm has a pencil pocket, and maybe with the pencils sticking out they would cover part of the flag, whereas the right arm has the neck seal pocket and a little more room. Furthermore, the referenced photo shows the flag was incorrectly positioned per U.S. Flag code. If they wanted to use a flag on the right sleeve, they would need to use the version with the field of stars facing forward. Perhaps someone noted that at some point and the correction was made.

Ronald Woods, NASA spacesuit expert for 45+ years:

I spoke with one of the suit technicians that supported Apollo 1 and he didn’t remember the flags being on the right arm. I have seen them in several pictures of the Apollo crew at different events, all on the right arm. Not sure at this time why and who may have sewn them on. During Apollo, we technicians would only sew the crew patches on the flight suits several weeks before launch.

Nicholas de Monchaux, author of Spacesuit: Fashioning Apollo:

I think there is a simple explanation, which is that the Apollo 1 suits were modified Gemini suits made by the David Clark Co., and the Apollo 7 suits were the first generation of [newer manufacturer] ILC suits. My guess is that two different manufacturers took two different approaches.

To learn more about this type of Apollo spacesuit, Universe Today approached Cathy Lewis — a curator who specializes in spacesuits at the Smithsonian National Air and Space Museum.

Intriguingly, it appears every NASA spacesuit that has a flag on it — besides the A1-C used in Apollo 1 — has its flag on the left. More from Lewis:

In all other suits in our collection where a flag is present, the flag is on the left. The collection includes suits made for NASA for programs and those made as prototypes and suits made for the USAF [United States Air Force] for the Manned Orbiting Laboratory program. Just as a note there were no flags in the Mercury suits that B.F. Goodrich made for NASA.

As the Bill Nye: The Science Guy show used to repeat … but wait, there’s more.

Lewis also gave us some great background on the suits used for Gemini and Apollo. The Apollo missions actually had two different sets of pressure garments — the A1-C and the A7-L, while the Gemini missions used the G4-Cs. Essentially, the G4-C and A1-C suits were the same thing (a high-altitude suit design adapted for space), made by the same prime manufacturer — David Clark Co. The next set of suits, the A7-L (made exclusively for space work), had ILC Dover as the prime manufacturer.

Lewis added that she does not see the flag switch as being tied to the change in manufacturer.

Lewis did a great job summarizing a lot of history in a few paragraphs, so we decided to include her entire e-mail here.

It is not likely to have anything to do with the manufacturers per se, because, DCC had placed the flag on the left shoulder for the Gemini program. The shift between DCC and ILC is a very long and complex story that began in 1962 with the first solicitations for suit prototypes for the Apollo program. ILC was selected as the suit manufacturer in 1965 with Hamilton Standard as the primary contractor by virtue of their government contracting and systems engineering experience.

That corporate relationship fizzled and left NASA with the option of putting off the design of the Moon-walking suits and falling back on their Earth orbital experience with DCC and Gemini for the early, Earth-orbiting Block I missions.

While DCC was making A1-C suits based on the G4-Cs that Ed White had used for the first US spacewalk, they were also competing with ILC, HS and others for the new Moon-walking suit contract.

The 1967 Apollo 204 fire changed NASA’s plans for different Block I and Block II (lunar orbiting and lunar landing) spacesuits. The resulting contract went again to ILC as primary with HS [Hamilton Standard] as sub with responsibility for the life support systems and systems integration for a suit that worked in Earth and lunar orbit and moon-walking.

Unless I am missing something, I don’t see an engineering issue over the placement of the flag.

If you have any other thoughts about why the flag switch occurred, feel free to let us know in the comments!