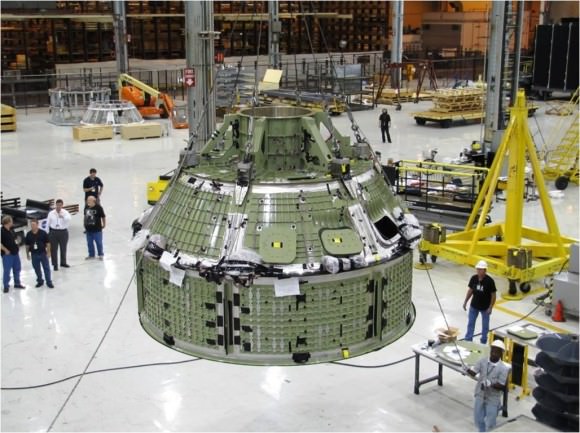

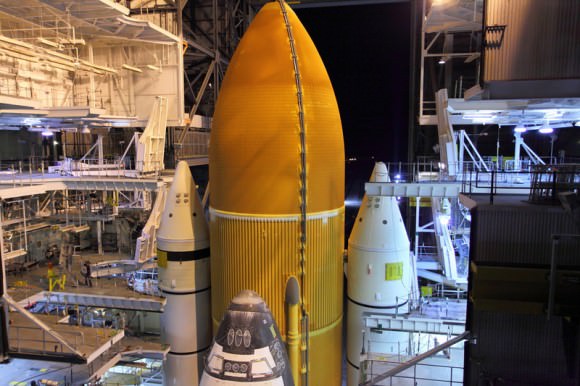

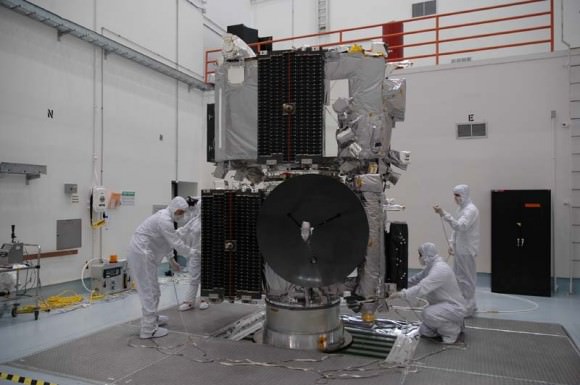

[/caption]The first Orion spacecraft has just been shipped from NASAs Michoud Assembly Facility in New Orlean’s to a Lockheed Martin manufacturing facility in Denver for crucial tests to simulate the harsh environment of deep space.

The Orion crew cabin – know as the Ground Test Article or GTA – was shipped by truck and will arrive in Denver on Feb. 14 according to a Lockheed Martin spokesperson.

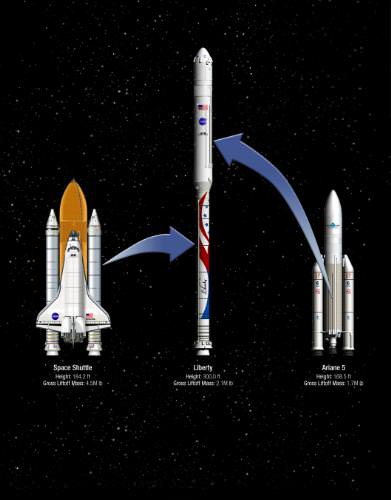

Orion is NASA’s next generation crew vehicle and will eventually replace the Space Shuttle system after the looming retirement of the three orbiter fleet, now reset to mid 2011.

The Orion crew exploration vehicle is capable of supporting missions to low Earth orbit (LEO), the Moon, Asteroids and Deep Space.

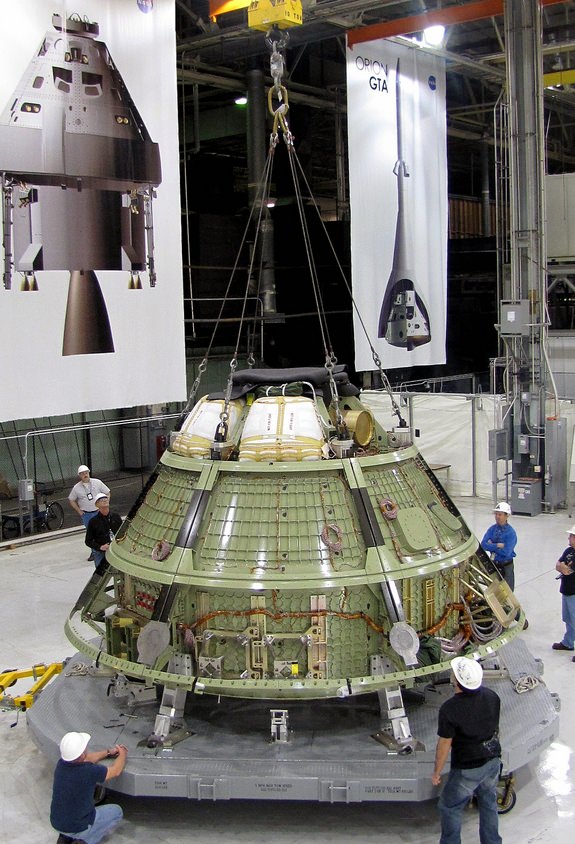

The next step at Denver is to install the heat shield and thermal protection backshell. The pathfinding vehicle will then be subjected to performance testing inside the acoustic and environmental testing chamber. The testing exercise ensures the vehicle can meet the challenges of ascent, on-orbit operations and safe landing.

“This is a significant milestone for the Orion project and puts us on the right path toward achieving the President’s objective of Orion’s first crewed mission by 2016,” said Cleon Lacefield, Lockheed Martin vice president and Orion program manager. “Orion’s upcoming performance tests will demonstrate how the spacecraft meets the challenges of deep-space mission environments such as ascent, launch abort, on-orbit operations, high-speed return trajectory, parachute deployment, and water landings in a variety of sea states.”

Engineers for Lockheed Martin successfully finished the initial construction and testing phase for this prototype Orion crew cabin at New Orleans. The final pieces of the Orion GTA were welded together in late May 2010 using a state of the art friction stir welding process. See photos below from my inspection tour of the newly welded Orion GTA.

The spacecraft underwent proof pressure testing this past fall. Several mass and volume simulators including the parachutes were installed by the technical team to ready the capsule for shipment.

In Denver, the vehicle will be bombarded with acoustic energy and vibrations to simulate flight like situations that correlate the structural environment inside and outside the vehicle. The tests will determine if the spacecraft was properly designed to survive the harsh rigors of spaceflight. Lessons learned will be incorporated into the tools and manufacturing processes that will eventually lead to a human rated production vehicle.

The GTA vehicle will then be transported to NASA’s Langley Research facility for drop tests to simulate, validate and certify a variety of water landing scenarios at the new Hydro Impact Basin. The Langley facility will be used to test and certify water landing for all human-rated spacecraft for NASA according to Lockheed.

NASA and Lockheed hope to launch the first unmanned Orion test flight in 2013 if the budget allows. Construction of the service module and other key components is in progress.

Orion has achieved other significant development milestones in the past year.

The emergency abort rocket was successfully tested on May 6, 2010 at the U.S. Army’s White Sands Missile Range near Las Cruces, N.M. The abort rocket is bolted atop the crew cabin and is designed to pull the capsule away from the launcher in a split second in an emergency and save astronauts lives.

“The Phase 1 Safety Review was completed in June 2010 and formally acknowledges that Orion’s design meets all of NASA’s critical safety requirements for a human-rated space flight vehicle for flights to low earth orbit (LEO), lunar and deep space missions,” according to Larry Price, Orion Deputy Program Manager at Lockheed Martin.

In the past year the Orion budget has been cut significantly by NASA due to lack of funding from the federal government and the outlook for future funding is uncertain. The new Congress is aiming to cut NASA’s research and development budget even further.

Lockheed Martin Space Systems Company is the prime contractor for Orion and designed and built the GTA as part of a multiyear contract awarded by NASA worth some $3.9 Billion US Dollars. The goal is to produce a new, US-built manned capsule capable of launching American astronauts into space in the post shuttle era.

As soon as the shuttles are retired – for lack of money – the United States will have no capability to loft American astronauts to the International Space Station (ISS) for at least several years. NASA – and all other ISS partners – will be wholly dependent on the Russian Soyuz capsules for launching astronauts to the ISS until either the Orion or commercially developed space taxis such as the Dragon spacecraft from SpaceX are ready for flight. The first operational unmanned Dragon was test flown in Dec 2010.

The Obama Administration sought to cancel Orion in Feb. 2010 as part of NASA’s Project Constellation Return to the Moon program, but then decided to continue Orion’s development after the cancellation proposal met strong bipartisan opposition in Congress.

Orion was to have been launched atop the Ares 1 rocket which has now been officially cancelled. NASA has started the design of a replacement for the Ares 1 which will most likely be a shuttle derived vehicle. Congress has mandated that the first test flight of the still undefined heavy lift rocket must take place by 2016.

Alternatively, Orion could be launched atop a Delta 4 Heavy booster after the rocket is man-rated.

Orion Crew Vehicle Construction Video

Watch this video to see how the first Orion spacecraft was constructed from pieces at NASA’s Michoud Assembly Facility in New Orleans. Credit: NASA