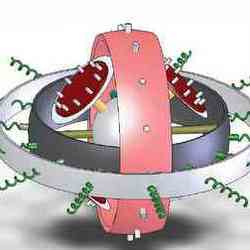

An artist’s rendering of the Integrated Powerhead Demonstrator. Image credit: NASA. Click to enlarge.

When you think of future rocket technology, you probably think of ion propulsion, antimatter engines and other exotic concepts.

Not so fast! The final chapter in traditional liquid-fueled rockets has yet to be written. Research is underway into a new generation of liquid-fueled rocket designs that could double performance over today’s designs while also improving reliability.

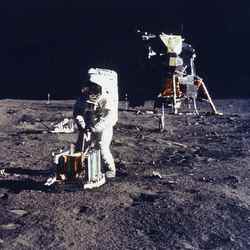

Liquid-fueled rockets have been around for a long time: The first liquid-powered launch was performed in 1926 by Robert H. Goddard. That simple rocket produced roughly 20 pounds of thrust, enough to carry it about 40 feet into the air. Since then, designs have become sophisticated and powerful. The space shuttle’s three liquid-fueled onboard engines, for instance, can exert more than 1.5 million pounds of combined thrust en route to Earth orbit.

You might assume that, by now, every conceivable refinement in liquid-fueled rocket designs must have been made. You’d be wrong. It turns out there’s room for improvement.

Led by the US Air Force, a group consisting of NASA, the Department of Defense, and several industry partners are working on better engine designs. Their program is called Integrated High Payoff Rocket Propulsion Technologies, and they are looking at many possible improvements. One of the most promising so far is a new scheme for fuel flow:

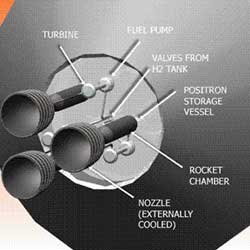

The basic idea behind a liquid-fueled rocket is rather simple. A fuel and an oxidizer, both in liquid form, are fed into a combustion chamber and ignited. For example, the shuttle uses liquid hydrogen as its fuel and liquid oxygen as the oxidizer. The hot gases produced by the combustion escape rapidly through the cone-shaped nozzle, thus producing thrust.

The details, of course, are much more complicated. For one, both the liquid fuel and the oxidizer must be fed into the chamber very rapidly and under great pressure. The shuttle’s main engines would drain a swimming pool full of fuel in only 25 seconds!

This gushing torrent of fuel is driven by a turbopump. To power the turbopump, a small amount of fuel is “preburned”, thus generating hot gases that drive the turbopump, which in turn pumps the rest of the fuel into the main combustion chamber. A similar process is used to pump the oxidizer.

Today’s liquid-fueled rockets send only a small amount of fuel and oxidizer through the preburners. The bulk flows directly to the main combustion chamber, skipping the preburners entirely.

One of many innovations being tested by the Air Force and NASA is to send all of the fuel and oxidizer through their respective preburners. Only a small amount is consumed there–just enough to run the turbos; the rest flows through to the combustion chamber.

This “full-flow staged cycle” design has an important advantage: with more mass passing through the turbine that drives the turbopump, the turbopump is driven harder, thus reaching higher pressures. Higher pressures equal greater performance from the rocket.

Such a design has never been used in a liquid-fueled rocket in the U.S. before, according to Gary Genge at NASA’s Marshall Space Flight Center. Genge is the Deputy Project Manager for the Integrated Powerhead Demonstrator (IPD)–a test-engine for these concepts.

“These designs we’re exploring could boost performance in many ways,” says Genge. “We’re hoping for better fuel efficiency, higher thrust-to-weight ratio, improved reliability–all at a lower cost.”

“At this phase of the project, however, we’re just trying to get this alternate flow pattern working correctly,” he notes.

Already they’ve achieved one key goal: a cooler-running engine. “Turbopumps using traditional flow patterns can heat up to 1800 C,” says Genge. That’s a lot of thermal stress on the engine. The “full flow” turbopump is cooler, because with more mass running through it, lower temperatures can be used and still achieve good performance. “We’ve lowered the temperature by several hundred degrees,” he says.

IPD is meant only as a testbed for new ideas, notes Genge. The demonstrator itself will never fly to space. But if the project is successful, some of IPD’s improvements could find their way into the launch vehicles of the future.

Almost a hundred years and thousands of launches after Goddard, the best liquid-fueled rockets may be yet to come.

Original Source: NASA Science Article