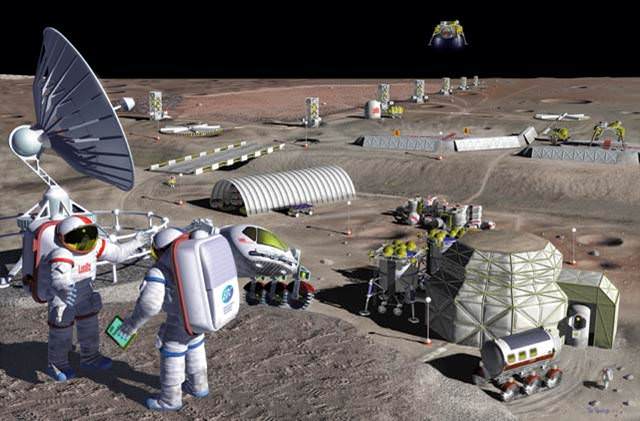

We’re still a few years away from the cute robots in Moon or Interstellar that help their human explorers. But if we want to build a base off of Earth, robotic intelligence will be essential to lower the cost and pave the way for astronauts, argues Philip Metzger, a former senior research physicist at NASA’s Kennedy Space Center.

In the last of a three-part series on getting a base ready on the moon or an asteroid, Metzger talks about the steps to get robots ready for the work and what barriers are standing in the way of accomplishing this.

UT: A table in your 2012 paper talks about the steps of lunar industry, starting with tele-operation and an “insect-like” robotic intelligence and then progressing through a few steps to “closely supervised autonomy” (mouse-like) and eventually “nearly full autonomy” (monkey-like) and “autonomous robotics” (human-like). What sorts of developments and how much time/resources would it take to progress through these steps?

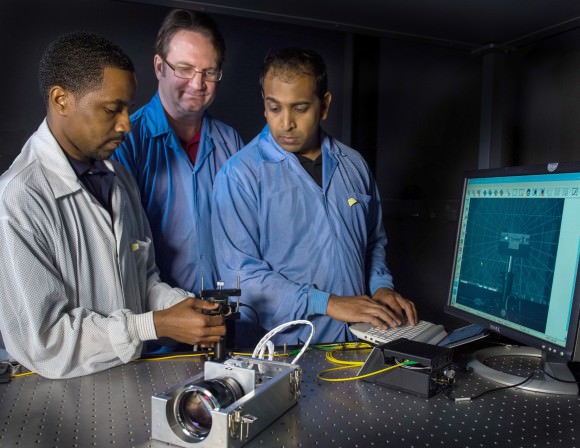

Most of the advances in robotic artificial intelligence are being made in software, but they also require advances in computing power. We mentioned in the paper that really only “mouse-like” robotics is needed for it to become successful in a near-Earth environment. We will need robots that can pick up a nut and screw it on a bolt without every motion being commanded from Earth. I believe we are on a trajectory to achieve these levels of autonomy already for robotics here on Earth. I am more concerned about developing robots that can be made easily in space without an extensive supply chain. For example, we need to invent a simple way to manufacture functional motors for the robots, minimizing the assembly tasks for robots making the same motors that are in themselves.

It is very difficult to estimate how long this will take. Here are some guiding ideas. First, robotics and manufacturing technologies are already on an explosive growth curve for terrestrial application, so we can ride on the coattails of that growth as we re-purpose the technologies for space. Second, we are not talking about inventing new capabilities. Everything we are talking about doing in space is already being done on Earth. All we need to do is discover what sets of equipment will function together as partial supply chains using space resources. We need to develop a sequence of partial supply chains, each more sophisticated than the last, each one capable of making a significant portion of the mass of the next. It will require innovation, but it is lower-risk innovation because we already have Earth’s more sophisticated industry to copy.

Third, we tend to estimate things will happen faster than they do in the near term, but slower than they do in the long term. Consider how much technology has changed in the past 200 years, and you will agree that it won’t take another 200 years to get this done. I think it will be much less than 100 years. I am betting it will be done within 50 years, and if we try hard we could do it in 20. In fact, if we really wanted to, and if we put up the money, I think we could do it in 10. But I’m telling people 20 to 50 years. Don’t worry if you think that’s too slow, because the fun of doing it can start immediately, and we will be doing really cool things in space long before the supply chain is complete.

UT: Is it really cheaper and scientifically viable to have a robotic fleet of spacecraft than humans, given development costs and the difficulties of making the robots as efficient to do work as humans?

Biological life needs a place like planet Earth. Humans need more than that; we also need a food chain, and in the final analysis we need an entire ecology of networked organisms interdependent on each other. And if we want to be more than hunters and gatherers, then civilization requires even more than that. We require the industrial supply chain: all the tools and machines and energy sources that we have developed over the past 10,000 years.

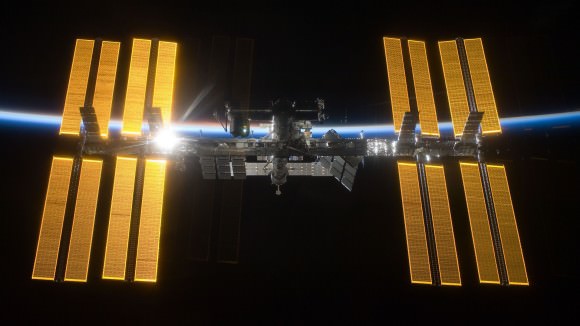

When we leave Earth, we need to take not just a canister of air to breath to replicate the physical conditions of our planet. We need the benefit of the entire ecosystem and the entire industrial base to support us. So far we have stayed close to Earth so we have never really “cut the surly bonds of Earth.” We take a consumable supply of food and spare parts from Earth with us, and we send up rockets to the space station when we need more. Even schemes to colonize Mars are depending on regular shipments of things from Earth. These are the things that make it expensive to put humans in space.

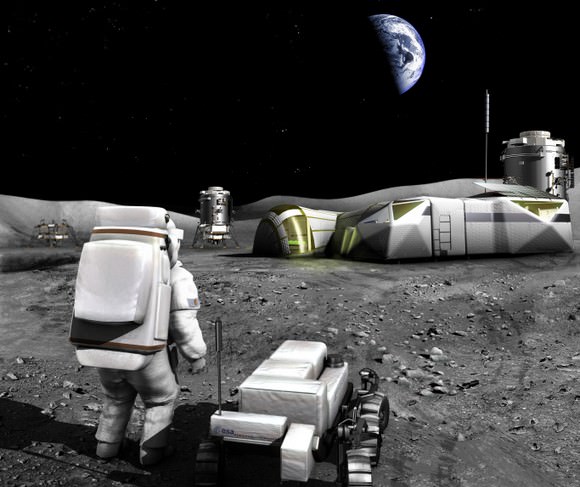

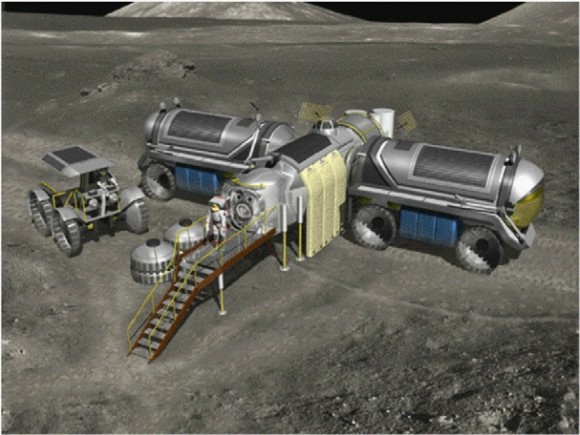

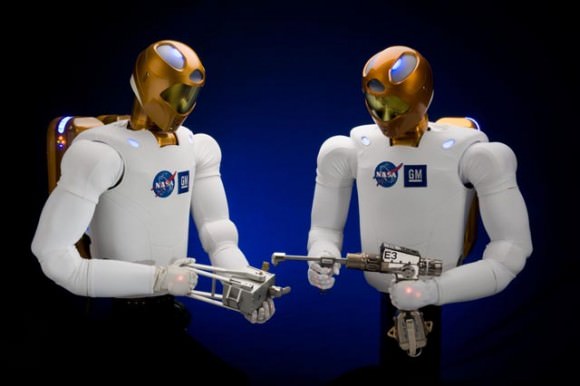

Robots, on the other hand, can be adapted to living in the space environment with nothing more from Earth. They can become the ecosphere and the supply chain in space that we humans require. Under our guidance, they can transform any environment analogously to how life has transformed the Earth. They can make air, purify water, and build the habitats and landing pads. Then, when we arrive, it will be vastly less expensive, and it will be safer, too. And this will free us up to spend our time in space doing the things that make us uniquely human. In the long term, robots will make space vastly cheaper for humans.

But yes, in the near-term there are things we can do more affordably in space by skipping development of robotic industry. We can shoot off sortie missions to various places, and when we are done we can zip back home before everyone dies. But that doesn’t fulfill our great potential as a species. It doesn’t take civilization to the next level. It doesn’t enable scientific research with a billion times the budget we have today. It doesn’t save our planet from overuse and industrial pollution. It doesn’t bring all humanity up to the standard of living many of us are enjoying in the west. It doesn’t make our existence safe in the galaxy. It doesn’t terraform new worlds. It doesn’t take us to other stars. All these things will be possible for almost no additional investment once we pay the tiny cost of bootstrapping industry in our solar system. It’s worth the cost.

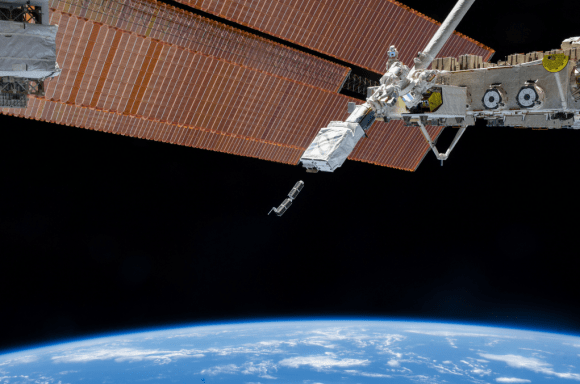

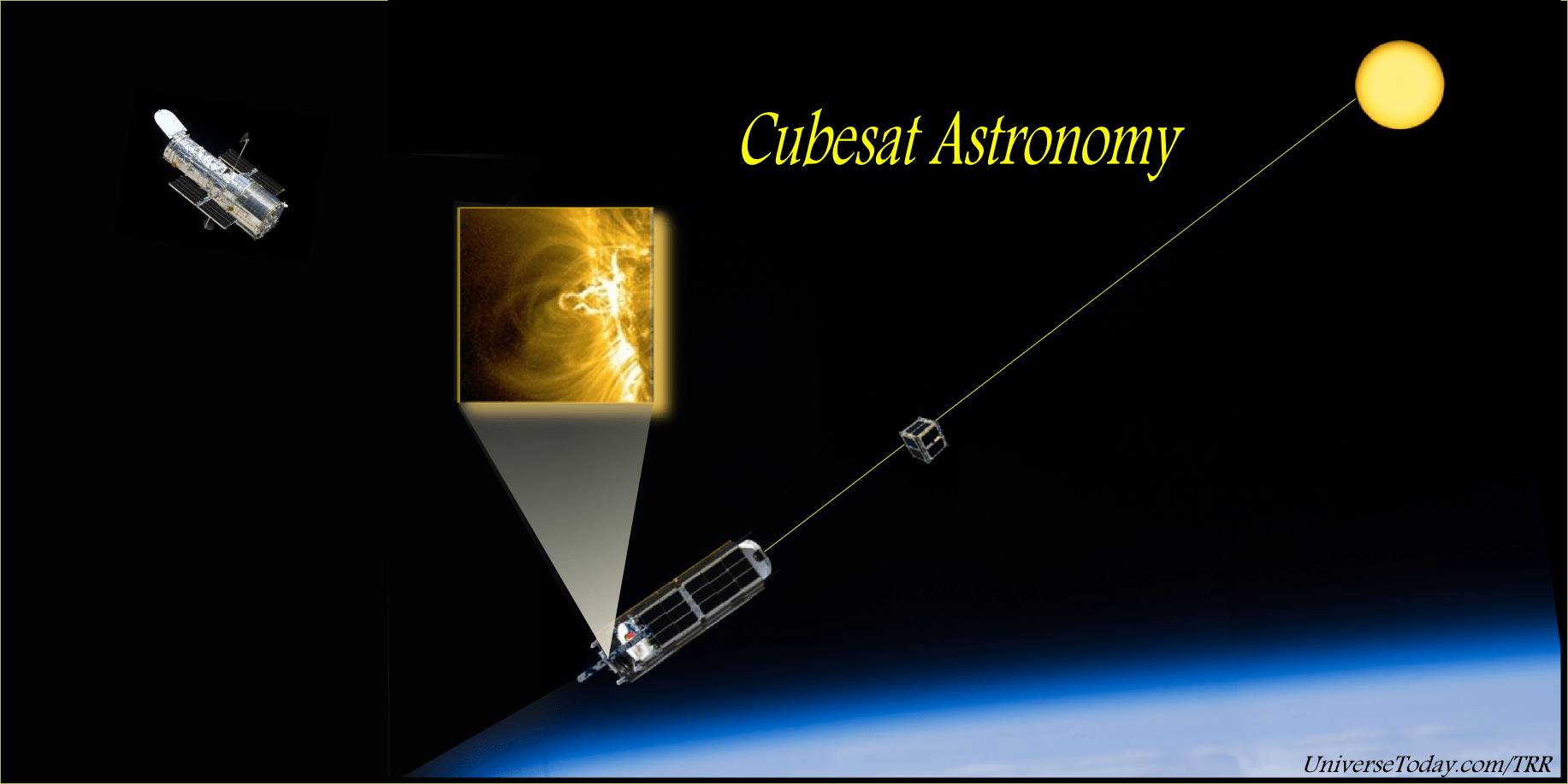

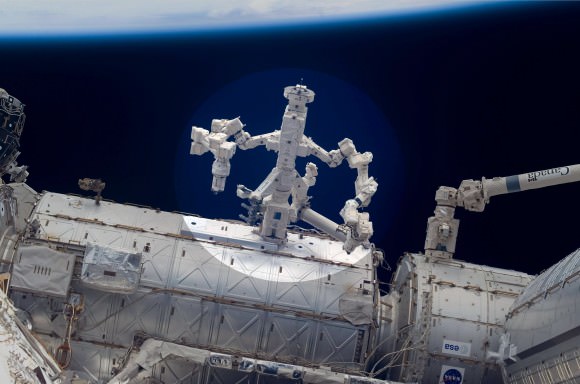

UT: We’re seeing a 3-D printer going on the International Space Station, and the European Space Agency has seriously talked about using this technology on the Moon. How close are we to actually doing this?

I know of several other groups also developing 3D printers that could work on the Moon or Mars to print things directly out of regolith. The KSC Swamp Works is pursuing one technological approach and has built a prototype, and Professor Behrokh Khoshnevis at the University of Southern California is pursing another approach and has printed many things already. My friend Jason Dunn who founded Made In Space, which put the 3D printer into the ISS, has another concept they are pursuing. My friends at NASA have told me that this is healthy, having a portfolio of technologies to pursue rather than just one.

To be ready for missions in space you have to do more than test things in a lab. You need to do testing in reduced gravity aircraft to see if the materials like regolith will flow properly, in vacuum chambers to make sure nothing overheats or jams, and in rugged field locations like a desert or on a volcano to check for dust problems or other unexpected effects. After that, you are ready to start designing the actual version that is going into space, to do the final qualification testing where you shake it and bake it half to death, to assemble and test the flight version, and to launch it.

So there are years of work ahead before all that is done. NASA’s direction is to put humans on Mars by the mid-2030’s, so we also have time and there is no rush. If we start to bootstrap space industry in the near-Earth region of space in parallel with getting ready for a Mars campaign then we will probably start testing regolith printers at field sites and making them interoperable with other equipment sooner than NASA presently needs them.

UT: What are the main barriers to robotic exploration on the Moon and beyond?

Budget is the only barrier. But taking a step back we might say a lack of vision is the only barrier because if enough of us understand what is now possible in space and how revolutionary it will be for humanity then there will be no lack of budget.

UT: Is there anything else you would like to add that I haven’t brought up yet?

We live in a very exciting time when these possibilities are being opened to us. It is exciting to think about the world our grandchildren will see, and it is exciting to think of what we can do to bring it about.

Whenever I speak on this topic, afterward the young people in the audience come up and start asking what they can do to get involved in space industry. They tell me that this is how they want to spend their lives. It gets that response because it is so compelling, so logical, and so right.

This is the third in a three-part series about building a space base. Two days ago: Why mine on the moon or an asteroid? Yesterday: How much money would it take?