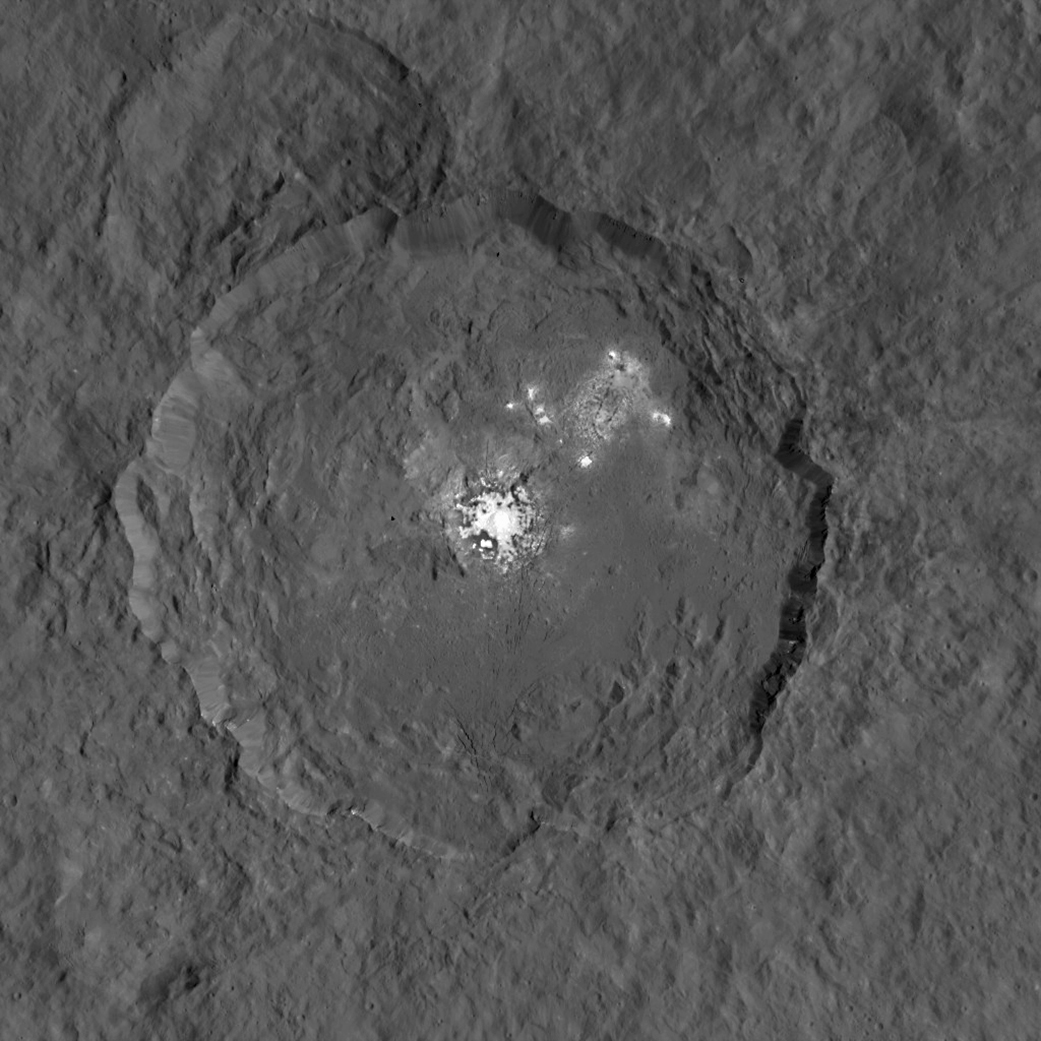

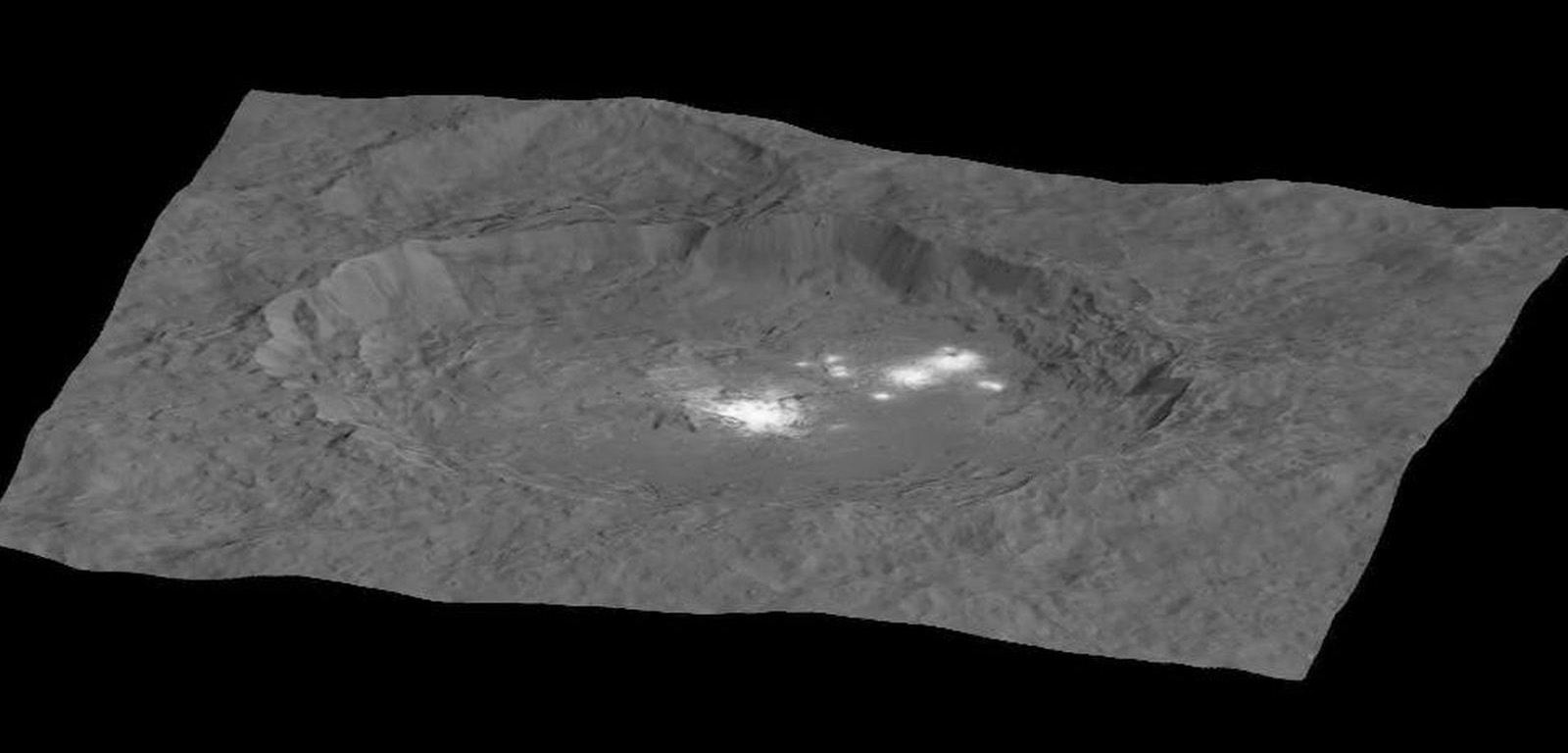

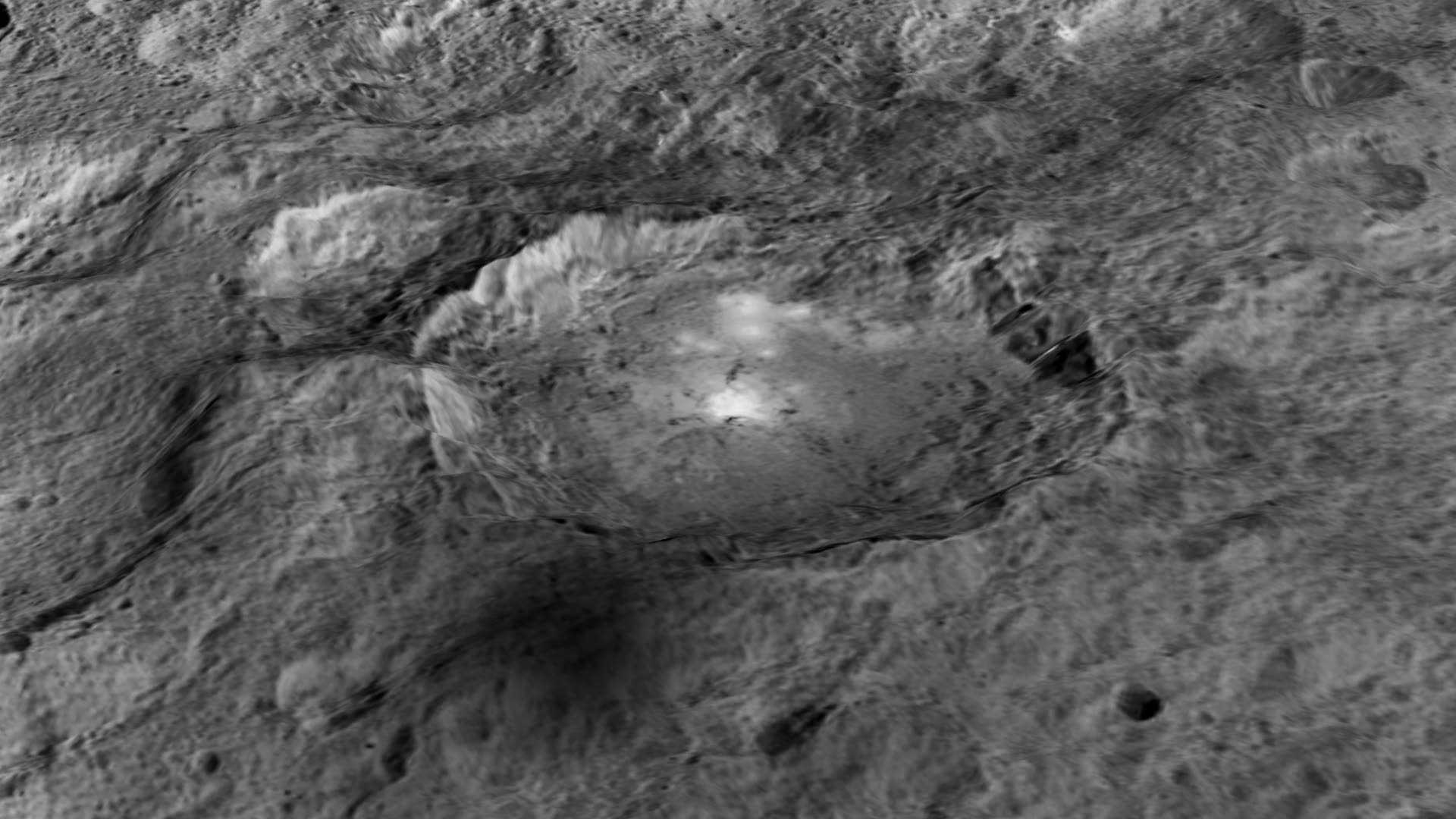

This image, made using images taken by NASA’s Dawn spacecraft during the mission’s High Altitude Mapping Orbit (HAMO) phase, shows Occator crater on Ceres, home to a collection of intriguing bright spots. Credits: NASA/JPL-Caltech/UCLA/MPS/DLR/IDA

Story/imagery updated[/caption]

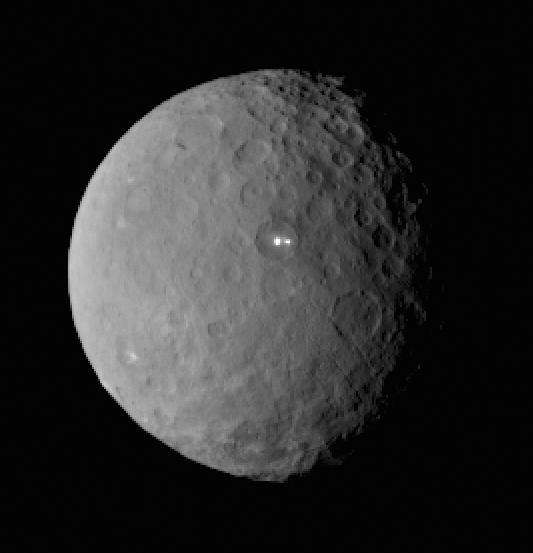

The question on everyone’s mind about Ceres is what the heck are those bizarre bright spots discovered by NASA’s Dawn orbiter?

Since scientists believe that Ceres occupies a “unique niche” in the solar system and apparently harbors subsurface ice or liquid oceans, could the bright spots arise from subsurface “water leakage?” To find out Universe Today asked Dawn’s Principal Investigator and Chief Engineer.

“The big picture that is emerging is that Ceres fills a unique niche,” Prof. Chris Russell, Dawn principal investigator told Universe Today exclusively.

“Ceres fills a unique niche between the cold icy bodies of the outer solar system, with their rock hard icy surfaces, and the water planets Mars and Earth that can support ice and water on their surfaces,” said Russell, of the University of California, Los Angeles.

And with Dawn recently arrived at its second lowest science mapping orbit of the planned mission around icy dwarf planet Ceres in mid-August, the NASA spacecraft is capturing the most stunningly detailed images yet of those ever intriguing bright spots located inside Occator crater.

The imagery and other science data may point to evaporation of salty water as the source of the bright spots.

“Occasional water leakage on to the surface could leave salt there as the water would sublime,” Russell told me.

Dawn is Earth’s first probe to explore any dwarf planet and the first to explore Ceres up close. It was built by Orbital ATK.

To shed more light on what still remains rather mysterious even today, NASA has just released the best yet imagery, which was taken at Dawn’s High Altitude Mapping Orbit (HAMO) phase and they raise as many questions as they answer.

Occator has captured popular fascination world-wide because the 60 miles (90 kilometers) diameter crater is rife with the alien bodies brightest spots and whose nature remains elusive to this day, over half a year after Dawn arrived in orbit this past spring on March 6, 2015.

The new imagery from Dawn’s current HAMO mapping orbit was taken at an altitude of just 915 miles (1,470 kilometers). They provide about three times better resolution than the images captured from its previous orbit in June, and nearly 10 times better than in the spacecraft’s initial orbit at Ceres in April and May, says the team.

So with the new HAMO orbit images in hand, I asked the team what’s the latest thinking on the bright spots nature?

Initially a lot of speculation focused on water ice. But the scientists opinions have changed substantially as the data pours in from the lower orbits and forced new thinking on alternative hypotheses – to the absolute delight of the entire team!

“When the spots appeared at first to have an albedo approaching 100%, we were forced to think about the possibility of [water] ice being on the surface,” Russell explained.

“However the survey data revealed that the bright spots were only reflecting about 50% of the incoming light.”

“We did not like the ice hypothesis because ice sublimes under the conditions on Ceres surface. So we were quite relieved by the lower albedo.”

“So what could be 50% reflective? If we look at Earth we find that when water evaporates on the desert it leaves salt which is reflective. We know from its density that water or ice is inside Ceres.”

“So the occasional water leakage on to the surface could leave salt there as the water would sublime even faster than ice.”

At this time no one knows how deep the potential ice deposit or water reservoir sources of the “water leakage” reside beneath the surface, or whether the bright salt spots arose from past or current activity and perhaps get replenished or enlarged over time. To date there is no evidence showing plumes currently erupting from the Cerean surface.

Video Caption: Circling Occator Crater on Ceres. This animation, made using data from NASA’s Dawn spacecraft, shows the topography of Occator crater on Ceres. Credits: Credit: NASA/JPL-Caltech/UCLA/MPS/DLR/IDA/PSI

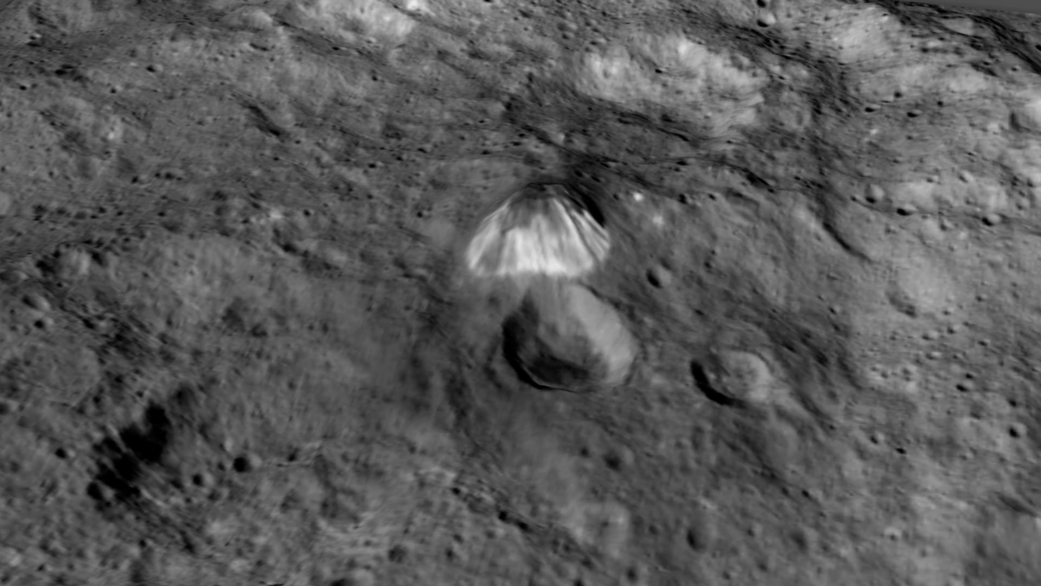

Dawn is an international science mission and equipped with a trio of state of the art science instruments from Germany, Italy and the US. They will elucidate the overall elemental and chemical composition and nature of Ceres, its bright spots and other wondrous geological features like the pyramidal mountain object.

I asked the PI and Chief Engineer to explain specifically how and which of the instruments is the team using right now at HAMO to determine the bright spots composition?

“The instruments that will reveal the composition of the spots are the framing camera [from Germany], the infrared spectrometer, and the visible spectrometer [both from the VIR instrument from Italy], replied Dr. Marc Rayman, Dawn’s chief engineer and mission director based at NASA’s Jet Propulsion Laboratory, Pasadena, California.

“Dawn arrived in this third mapping orbit [HAMO] on Aug. 13. It began this third mapping phase on schedule on Aug. 17.”

But much work remains to gather and interpret the data and discern the identity of which salts are actually present on Ceres.

“While salts of various sorts have the right reflectance, they are hard to distinguish from one another in the visible,” Russell elaborated to Universe Today.

“That is one reason VIR is working extra hard on the IR spectrum. Scientists are beginning to speculate on the salts. And to think about what salts could be formed in the interior.”

“That is at an early stage right now,” Russell stated.

“I know of nothing exactly like these spots anywhere. We are excited about these scientific surprises!”

Occator crater lies in Ceres northern hemisphere.

“There are other lines of investigation besides direct compositional measurement that will provide insight into the spots, including the geological context,” Rayman told Universe Today.

Each of Dawn’s two framing cameras is also outfitted with a wheel of 7 color filters, explained Joe Makowski, Dawn program manager from Orbital ATK, in an interview.

Different spectral data is gathered using the different filters which can be varied during each orbit.

“So far Dawn has completed 2 mapping orbit cycles of the 6 cycles planned at HAMO.”

Each HAMO mapping orbit cycle lasts 11 days and consists of 14 orbits lasting 19 hours each. Ceres is entirely mapped during each of the 6 cycles. The third mapping cycle just started on Wednesday, Sept. 9.

The instruments will be aimed at slightly different angle in each mapping cycle allowing the team to generate stereo views and construct 3-D maps.

“The emphasis during HAMO is to get good stereo data on the elevations of the surface topography and to get good high resolution clear and color data with the framing camera,” Russell explained.

“We are hoping to get lots of VIR IR data to help understand the composition of the surface better.”

“Dawn will use the color filters in its framing camera to record the sights in visible and infrared wavelengths,” notes Rayman.

“Dawn remains at HAMO until October 23. Then it begins thrusting with the ion propulsion thrusters to reach its lowest mapping orbit named LAMO [Low Altitude Mapping Orbit],” Makowski told me.

“Dawn will arrive at LAMO on December 15, 2015.”

That’s a Christmas present we can all look forward to with glee!

What is the teams reaction, interplay and interpretation regarding the mountains of new data being received from Dawn? How do the geologic processes compare to Earth?

“Dawn has transformed what was so recently a few bright dots into a complex and beautiful, gleaming landscape,” says Rayman. “Soon, the scientific analysis will reveal the geological and chemical nature of this mysterious and mesmerizing extraterrestrial scenery.”

“We do believe we see geologic processes analogous to those on Earth – but with important Cerean twists,” Russell told me.

“However we are at a point in the mission where conservative scientists are interpreting what we see in terms of familiar processes. And the free thinkers are imagining wild scenarios for what they see.”

“The next few weeks (months?) will be a time where the team argues amongst themselves and finds the proper compromise between tradition and innovation,” Russell concluded elegantly.

A batch of new results from Dawn at Ceres are expected to be released during science presentations at the European Planetary Science Congress 2015 being held in Nantes, France from 27 September to 2 October 2015.

The Dawn mission is expected to last until at least March 2016, and possibly longer, depending upon fuel reserves.

“It will end some time between March and December,” Rayman told me.

The science objectives in the LAMO orbit could be achieved as soon as March. But the team wants to extend operations as long as possible, perhaps to June or beyond, if the spacecraft remains healthy and has sufficient hydrazine maneuvering fuel and NASA funding to operate.

“We expect Dawn to complete the mission objectives at Ceres by March 2016. June is a the programmatic milestone for end of the nominal mission, effectively a time margin,” Makowski told Universe Today.

“The team is working to a well-defined exploration plan for Ceres, which we expect to accomplish by March, if all goes well.”

“At launch Dawn started with 45 kg of hydrazine. It has about 21 kg of usable hydrazine onboard as of today.”

“We expect to use about 15 kg during the nominal remaining mission,” Makowski stated.

Therefore Dawn may have roughly 5 kg or so of hydrazine fuel for any extended mission, if all goes well, that may eventually be approved by NASA. Of course NASA’s budget depends also on what is approved by the US Congress.

Dawn was launched on September 27, 2007 by a United Launch Alliance (ULA) Delta II Heavy rocket from Space Launch Complex-17B (SLC-17B) at Cape Canaveral Air Force Station, Florida.

Stay tuned here for Ken’s continuing Earth and planetary science and human spaceflight news.