KENNEDY SPACE CENTER, FL – NASA is picking up the pace of assembly operations for the Orion capsule, America’s next crew vehicle destined to carry US astronauts to Asteroids, the Moon, Mars and Beyond.

Just over a year from now in September 2014, NASA will launch Orion on its first test flight, an unpiloted mission dubbed EFT-1.

At NASA’s Kennedy Space Center in Florida, expert work crews are already hard at work building a myriad of Orion’s key components, insuring the spacecraft takes shape for an on time liftoff.

In 2014 Orion will blast off to Earth orbit atop a mammoth Delta IV Heavy booster, the most powerful booster in America’s rocket fleet following the retirement of NASA’s Space Shuttle orbiters in 2011.

On later flights Orion will blast off on the gargantuan Space Launch System (SLS), the world’s most powerful rocket which is simultaneously under development by NASA.

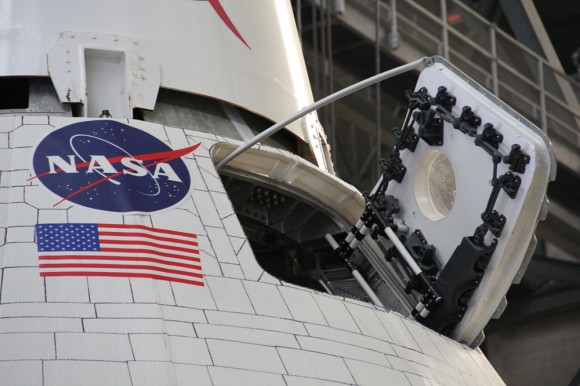

At the very top of the Orion launch stack sits the Launch Abort System (LAS) – a critically important component to ensure crew safety, bolted above the crew module.

In case of an emergency situation, the LAS is designed to ignite within milliseconds to rapidly propel the astronauts inside the crew module away from the rocket and save the astronauts lives.

The LAS is one of the five primary components of the flight test vehicle for the EFT-1 mission.

Prior to any launch from the Kennedy Space Center, all the rocket components are painstakingly attached piece by piece.

Final assembly for EFT-1 takes place inside the iconic Vehicle Assembly Building (VAB).

To get a head start on assembly with the launch date relentlessly approaching, technicians have been practicing lifting and stacking techniques for several months inside the VAB transfer aisle using the 6 ton LAS pathfinder replica and mock ups of the Orion crew and service modules.

Conducting the practice sessions now with high fidelity replicas serves multiple purposes, including anticipating and solving problems now before the real equipment arrives, as well as to keep the teams proficient between the years long launch gap between the finale of the Space Shuttle program and the start up of the Orion/SLS deep space exploration program.

Delicate maneuvers like lifting, rolling, rotating, stacking, gimballing and more of heavy components requiring precision placements is very demanding and takes extensive practice to master.

There is no margin for error. Human lives hang in the balance.

The same dedicated crews that assembled NASA’s Space Shuttles inside the VAB for 3 decades are assembling Orion. And they are using the same equipment.

“The breakover, taking the LAS from horizontal to vertical, is not as easy as it sometimes seems, but the VAB guys are exceptional, they are really good at what they do so they really didn’t have a problem,” says Douglas Lenhardt, who is overseeing the Orion mock-up and operations planning for the Ground Systems Development and Operations program, or GSDO.

Simulations with computer models are extremely helpful, but real life situations can be another matter.

“Real-life, things don’t always work perfectly and that’s why it really does help having a physical model,” says Lenhardt.

Credit: Ken Kremer/kenkremer.com

During the unmanned Orion EFT-1 mission, the capsule will fly on a two orbit test flight to an altitude of 3,600 miles above Earth’s surface, farther than any human spacecraft has gone in 40 years.

Credit: Ken Kremer/kenkremer.com