Image credit: Scaled

Scaled Composites announced today that it has selected San Diego-based SpaceDev to build the rocket engine for SpaceShipOne. The hybrid engine uses nitrous oxide and rubber, and was chosen for both safety and performance. SpaceShipOne is Scaled Composite’s entrant into the X-Prize; a $10 million prize to the first private company able to launch a 2-person crew to an altitude of 100 km. No future plans or launch dates have been announced but the spacecraft must complete a successful flight before the end of 2004 to claim the prize.

Four years ago, Scaled conducted a study of rocket engine technologies that were appropriate for its future manned sub-orbital spaceship design. The results of this study were that a hybrid configuration using nitrous oxide (liquid N2O) and HTPB (rubber) propellants would likely provide the safest solution with operating characteristics that would complement the intended mission.

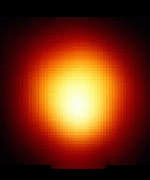

In Jan 2000, Scaled defined a new integrated concept for the hybrid motor that allowed the entire propulsion system to be mounted to the spaceship by simple skirt flanges on the oxidizer tank. This concept, which cantilevers the case and nozzle directly to the tank, required an advanced all-composite design approach. By early 2001, Scaled had committed to developing the two main motor composite components in-house: The first is the nitrous oxide tank, a composite liner laid up onto titanium flanges, with a graphite over-wrap provided by Thiokol. The second is a unitized fuel case/nozzle component fabricated using a high-temperature composite insulator with a graphite/epoxy structure laid up onto an ablative nozzle supplied by AAE Aerospace.

In mid 2001, Scaled awarded contracts to two competing small businesses for the “rocket science”. Each company was independently responsible for the development of the motor’s ignition system, main control valve, injector, tank bulkheads, electronic controls, fill/dump/vent systems and fuel casting. The vendors, Environmental Aeroscience Corporation (eAc) of Miami and SpaceDev (SD) of San Diego, were also tasked with conducting the ground firing tests of their motor systems in Scaled’s test facility during the development phase.

In June 2002, Scaled selected eAc to supply the components at the tanks’ front end: the nitrous fill, vent and dump system components and associated plumbing. Both vendors continued the development of all the other propulsion components.

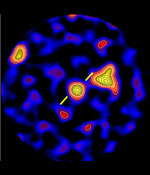

The ground firing development program started in November 2002 with a 15 second run by the SpaceDev team and ended early this month with a 90-second run by eAc. Both vendors demonstrated full design-duration firings during the nine-month development phase. All tests have exclusively used 100% flight hardware, with no boilerplate components and both vendors’ motor systems met the contracted performance. The tests validated the inherent safety of hybrid type motors, with no instances of structural failure, hot-gas breach, explosion or other anomaly that would have put SpaceShipOne in jeopardy.

Because both teams were so closely matched, and since both have developed satisfactory motors the process to select one of these vendors to enter the motor qualification and flight test phase was difficult. However, today, Scaled is pleased to announce that it has awarded the contract for propulsion support for the SpaceShipOne flight test phase to SpaceDev, of San Diego.

Scaled now looks forward to entering into the historic phase of private manned space flight.

Original Source: Scaled Composites News Release