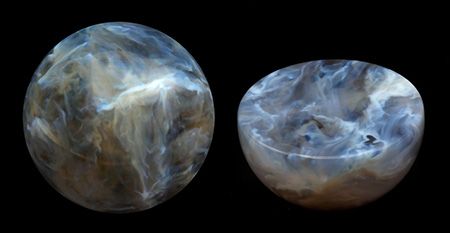

In this decade and the next, multiple space agencies will send crewed missions to the Moon for the first time since the Apollo Era. These missions will culminate in the creation of permanent lunar infrastructure, including habitats, using local resources – aka. In-situ resource utilization (ISRU). This will include lunar regolith, which robots equipped with additive manufacturing (3D printing) will use to fashion building materials. These operations will leverage advances in teleoperation, where controllers on Earth will remotely operate robots on the lunar surface.

According to new research by scientists at the University of Bristol, the technology is one step closer to realization. Through a virtual simulation, the team completed a sample collection task and sent commands to a robot that mimicked the simulation’s actions in real life. Meanwhile, the team monitored the simulation without requiring live camera streams, which are subject to a communications lag on the Moon. This project effectively demonstrates that the team’s method is well-suited for teleoperations on the lunar surface.

Continue reading “New Simulation Will Help Future Missions Collect Moon Dust”