The first tier of seven tiers for Crew Access Tower is moved from its construction yard to Space Launch Complex-41 at Cape Canaveral Air Force Station in Florida on Sept 9, 2015. The tower will provide access at the pad for astronauts and ground support teams to the Boeing CST-100 Starliner launching atop a United Launch Alliance Atlas V rocket. Photo credit: NASA/Dmitrios Gerondidakis

Story/photos updated[/caption]

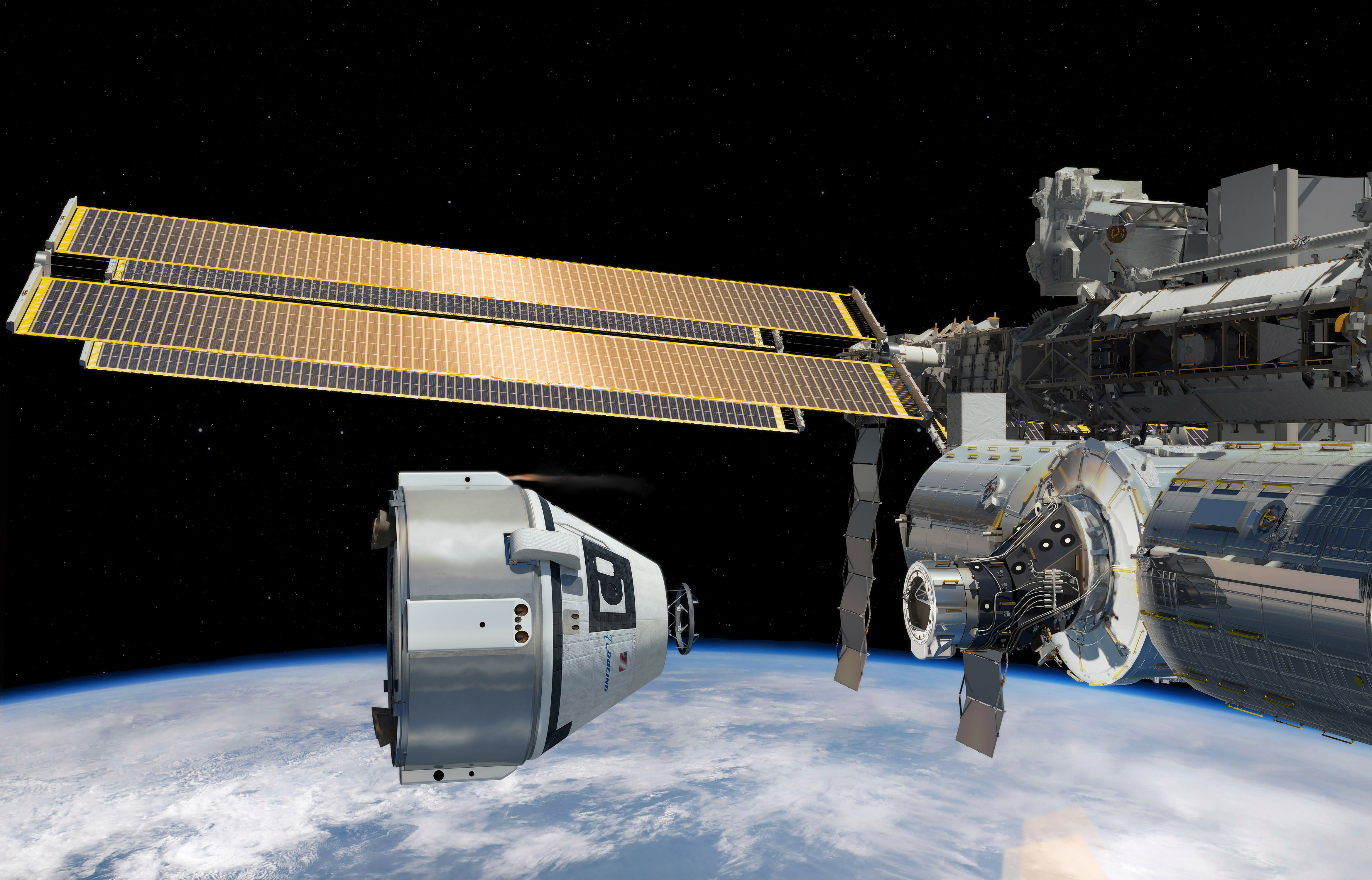

KENNEDY SPACE CENTER, FL – Restoring America’s human path back to space from US soil kicks into high gear at last as construction starts on erecting the new crew access tower on the Atlas V launch pad that will soon propel Americans astronauts riding aboard the commercially developed Boeing CST-100 ‘Starliner’ taxi to the Earth-orbiting International Space Station (ISS).

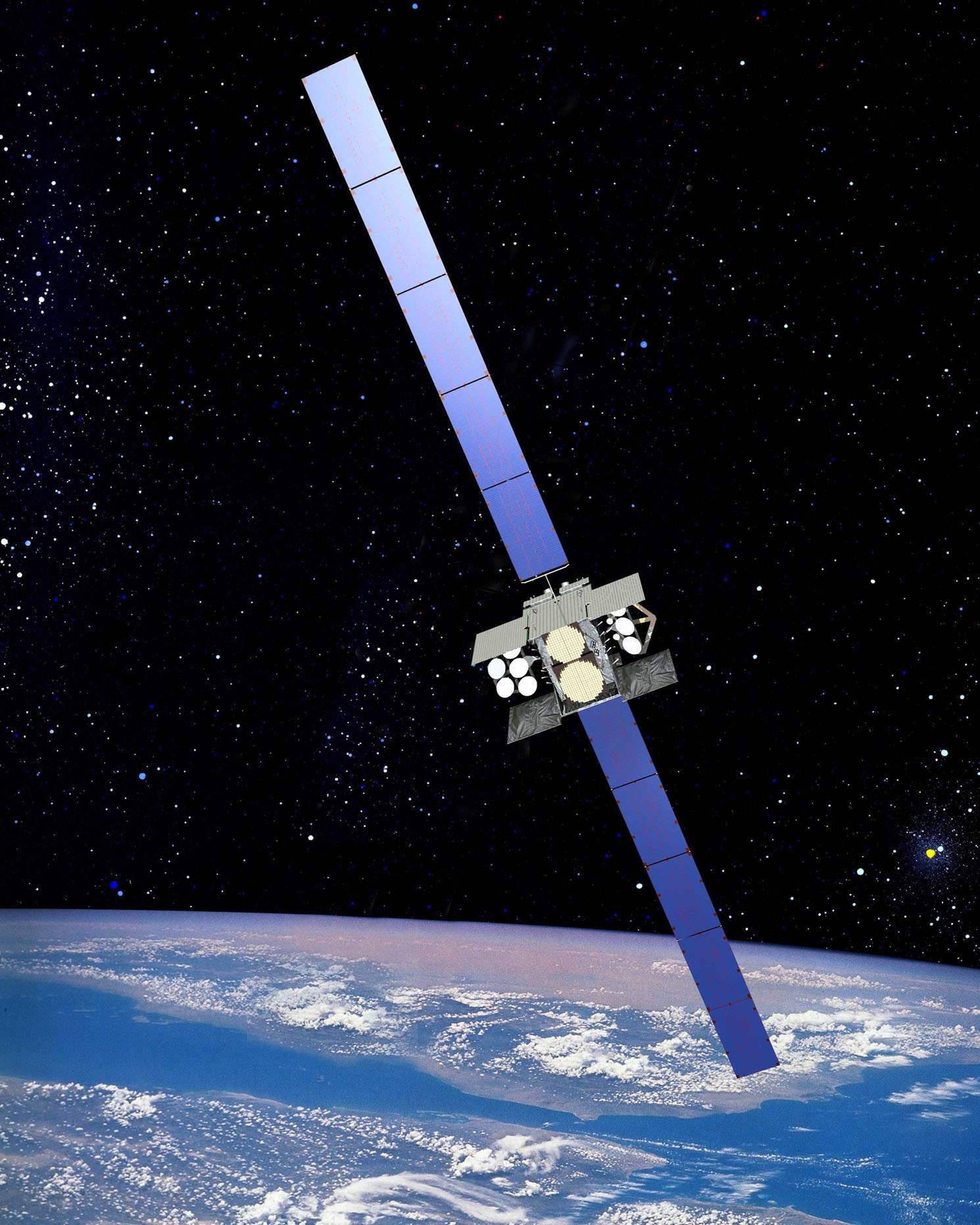

The last hurdle to begin stacking the crew access tower at the United Launch Alliance Atlas V complex-41 launch pad on Cape Canaveral Air Force Station, Florida was cleared with the magnificent predawn blastoff of the U.S. Navy’s MUOS-4 communications satellite on Sept. 2 – following a two day weather delay due to Tropical Storm Erika.

“Everything is on schedule,” Howard Biegler, ULA’s Human Launch Services Lead, told Universe Today during an exclusive interview. “The new 200-foot-tall tower structure goes up rather quickly at launch pad 41.”

The access tower essentially functions as the astronauts walkway to the stars.

“We start stacking the crew access tower [CAT] after the MUOS-4 launch and prior to the next launch after that of Morelos-3,” Beigler said in a wide ranging interview describing the intricately planned pad modifications and tower construction at the Atlas V Space Launch Complex 41 facility at Cape Canaveral.

Depending on the always tricky weather at the Cape, more than half the tower should be “installed prior to MORELOS-3’s launch on Oct. 2. The balance of the CAT will take form after the launch.”

The crew access tower is a critical space infrastructure element and absolutely essential for getting Americans back to space on American rockets for the first time since NASA’s shuttles were retired in 2011. That action forced our total dependence on the Russian Soyuz capsule for astronaut rides to the space station.

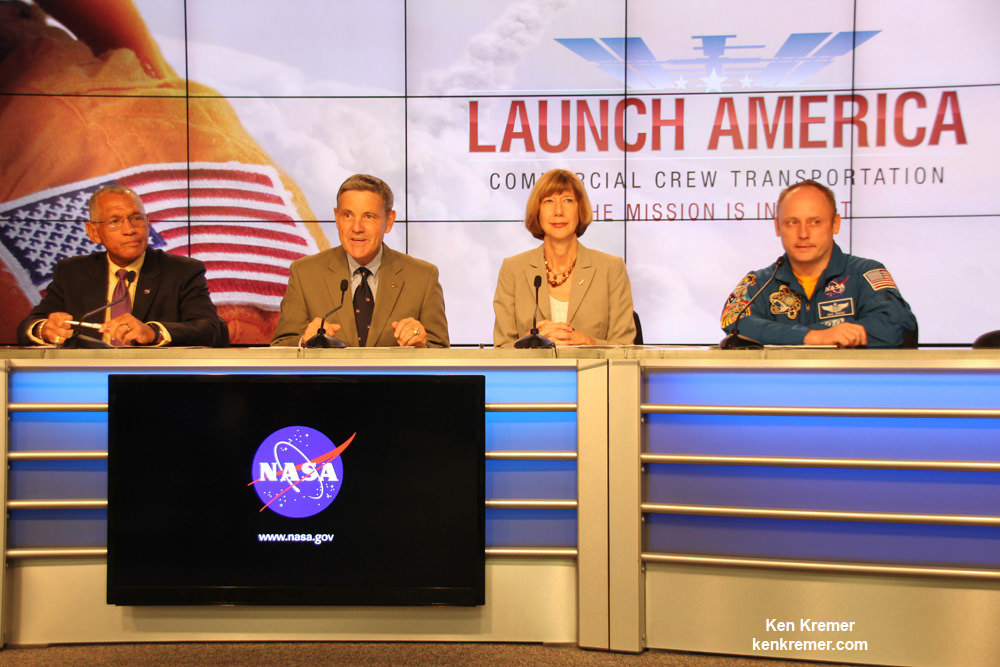

Boeing was awarded a $4.2 Billion contract in September 2014 by NASA Administrator Charles Bolden to complete development and manufacture of the CST-100 space taxi under the agency’s Commercial Crew Transportation Capability (CCtCap) program and NASA’s Launch America initiative. SpaceX also received a NASA award worth $2.6 Billion to build the Crew Dragon spacecraft for launch atop the firms man-rated Falcon 9 rocket.

Starliner is a key part of NASA’s overarching strategy to send Humans on a “Journey to Mars” in the 2030s.

The tower is of modular design for ease of assembly at the always busy Atlas launch pad.

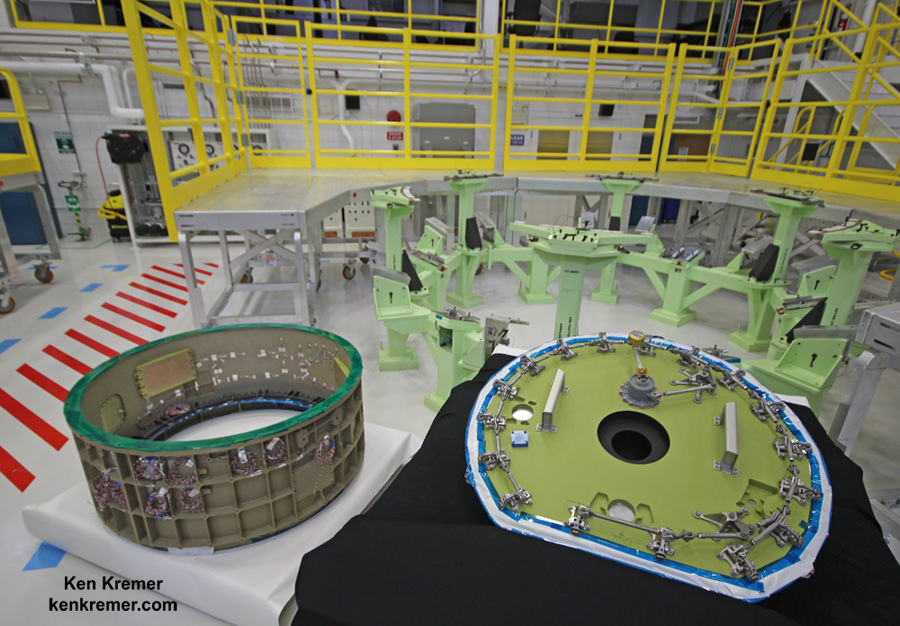

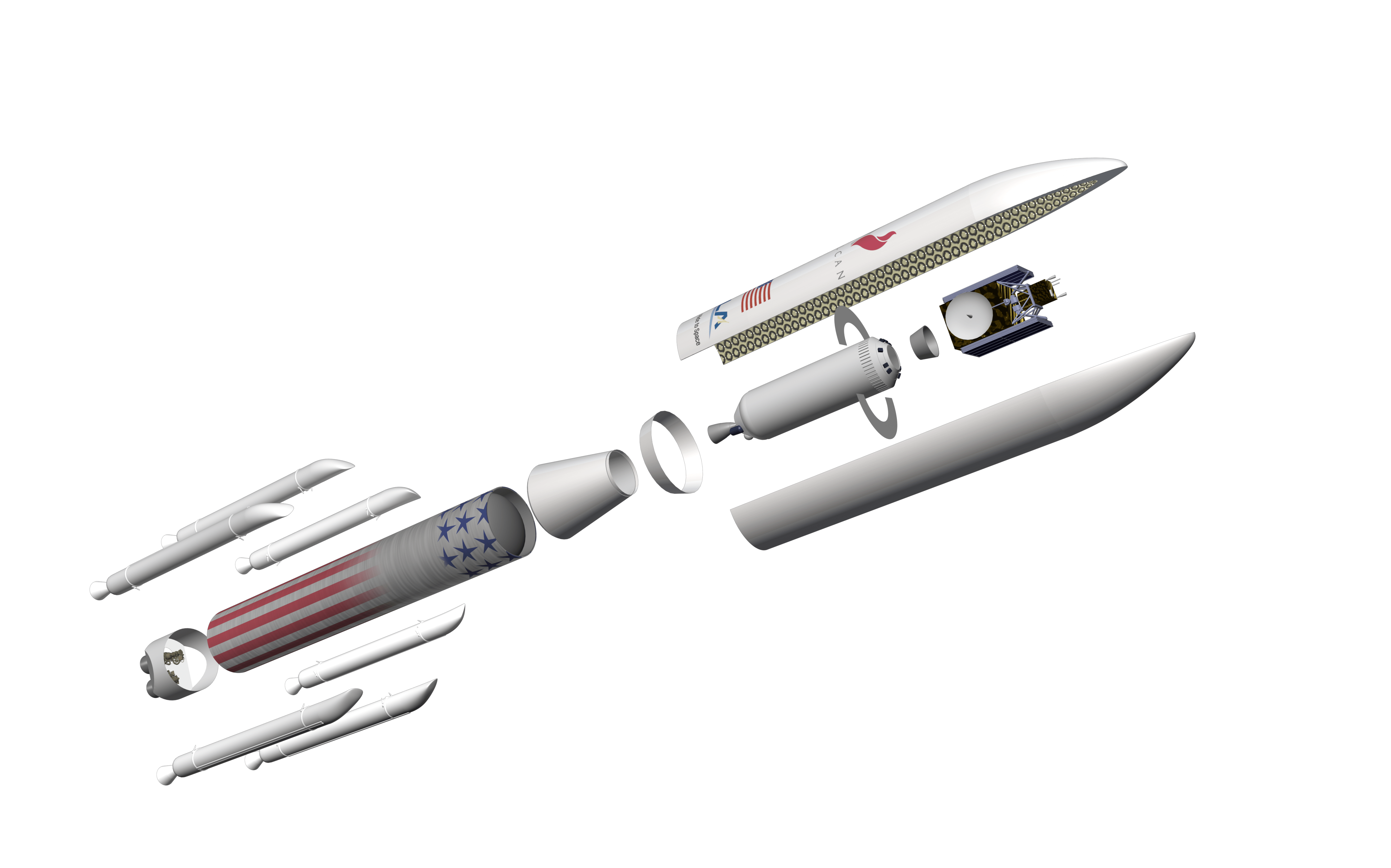

“The crew tower is comprised of seven major tiers, or segments,” Beigler explained. “The building of the tiers went right on schedule. Each tier is about 20 feet square and 28 feet tall.”

Five of the seven tiers will be installed ahead of the next Atlas launch in early October, depending on the weather which has been difficult at the Cape.

“Our plan is to get 5 tiers and a temporary roof installed prior to MORELOS-3’s launch on October 2.”

“We have been hit hard with weather and are hopeful we can gain some schedule through the weekend. The balance of the CAT will take form after the 10/2 launch with the 7th tier planned to go up on 10/13 and roof on 10/15,” Biegler explained.

The newly named ‘Starliner’ space taxi will launch atop a newly human-rated Atlas V booster as soon as mid-2017, say NASA, ULA and Boeing officials.

But before astronauts can even climb aboard Starliner atop the Atlas rocket, ULA and Boeing first had to design, build and install a brand new tower providing access to the capsule for the crews and technicians.

Pad 41 is currently a “clean pad” with no gantry and no walkway to ‘Starliner’ because the Atlas V has only been used for unmanned missions to date.

The CST-100 ‘Starliner’ is at the forefront of ushering in the new commercial era of space flight and will completely revolutionize how we access, explore and exploit space for the benefit of all mankind.

This is the first new Crew Access Tower to be built at the Cape in decades, going back to NASA’s heyday and the Apollo moon landing era.

The tier segments were assembled about four miles down the road at the Atlas Space Operations Center on Cape Canaveral – so as not to disrupt the chock full manifest of Atlas rockets launching on a breakneck schedule for the NASA, military and commercial customers who ultimately pay the bills to keep ULA afloat and launch groundbreaking science probes and the most critical national security payloads vital to national defense.

“Each segment was outfitted with additional steel work, as well as electrical, plumbing and the staircase. Then they will be transported 3.9 miles out to the pad, one at a time on a gold hoffer and then we start erecting.”

The first two tiers were just transported out to pad 41. Installation and stacking of one tier on top of another starts in a few days.

“We are very pleased with the progress so far,” Biegler told me. “Everything is on schedule and has gone remarkably well so far. No safety or workmanship issues. It’s all gone very well.”

“The first tier is obviously the most critical [and will take a bit longer than the others to insure that everything is being done correctly]. It has to be aligned precisely over the anchor bolts on the foundation at the pad. Then it gets bolted in place.”

“After that they can be installed every couple of days, maybe every three days or so. The pieces of the tower will go up quickly.”

“Construction by the Hensel Phelps team started in January 2015,” Biegler said.

Erecting the entire tower is the next step. After stacking the tiers is fully completed later this year then comes structure, testing and calibration work over the next year.

“After tower buildup comes extensive work to outfit the tower with over 400 pieces of outboard steel that have to be installed. That takes much longer,” Biegler said.

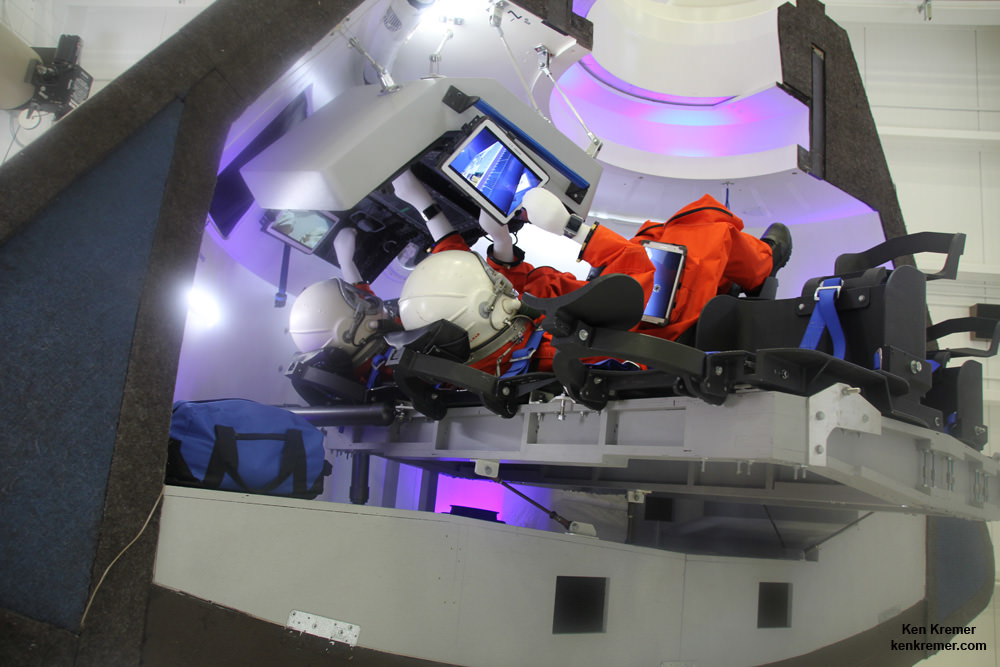

“Designed with modern data systems, communications and power networks integrated and protected from blast and vibration, plus an elevator, the Crew Access Tower has been built with several features only a fully suited astronaut could appreciate, such as wider walkways, snag-free railings and corners that are easy to navigate without running into someone,” according to NASA officials.

Just like the shuttle, “the tower will also be equipped with slide wire baskets for emergency evacuation to a staged blast-resistant vehicle.”

“At the very top is the area that protects the access arm and provides the exit location for the emergency egress system. It will all be stick built from steel out at the pad,” Biegler elaborated.

The access arm with the walkway that astronauts will traverse to the Starliner capsule is also under construction. It is about 180 feet above ground.

Astronauts will ride an elevator up the tower to the access arm, and walk through it to the white room at the end to board the Starliner capsule.

“The arm along with the white room and torque tube are being fabricated in Florida. It will all be delivered to the pad sometime around next June [2016],” Biegler stated.

“We built a test stand tower for the access arm at our Oak Hill facility to facilitate the installation process. We mount the arm and the hydraulic drive system and then run it through its paces prior to its delivery to the pad.”

“The access arm – including the torque tube out to the end – is just over 40 feet in length.”

“We will integrate it off line because we don’t have a lot of time to troubleshoot out at the pad. So we will hook up all its drive systems and electronics on the test structure stand.”

“Then we will spend about 3 months testing it and verifying that everything is right. We’ll use laser lining to know it all precisely where the arm is. So that when we bring it out to the pad we will know where it is to within fractions of an inch. Obviously there will be some minor adjustments up and down.”

“That way in the end we will know that everything in the arm and the hydraulic drive system are working within our design specs.”

When the arm is finally installed on the crew access tower it will be complete, with the white room and environmental seal already attached.

“It will stow under the crew access tower, which is located west and north of the launch vehicle. The arm will swing out about 120 degrees to the crew module to gain access and was strategically picked to best fit the features and foundation at the existing pad structure.”

Tower construction takes place in between Atlas launches and pauses in the days prior to launches. For example the construction team will stand down briefly just ahead of the next Atlas V launch currently slated for Oct. 2 with the Mexican governments Morelos-3 communications satellite.

Starliners’ actual launch date totally depends on whether the US Congress provides full funding for NASA’s commercial crew program (CCP).

Thus far the Congress has totally failed at providing the requested CCP budget to adequately fund the program – already causing a 2 year delay of the first flight from 2015 to 2017.

Boeing is making great progress on manufacturing the first CST-100 Starliner.

Barely a week ago, Boeing staged the official ‘Grand Opening’ ceremony for the craft’s manufacturing facility held at the Kennedy Space Center on Friday, Sept 4. 2015 – attended by Universe Today as I reported here.

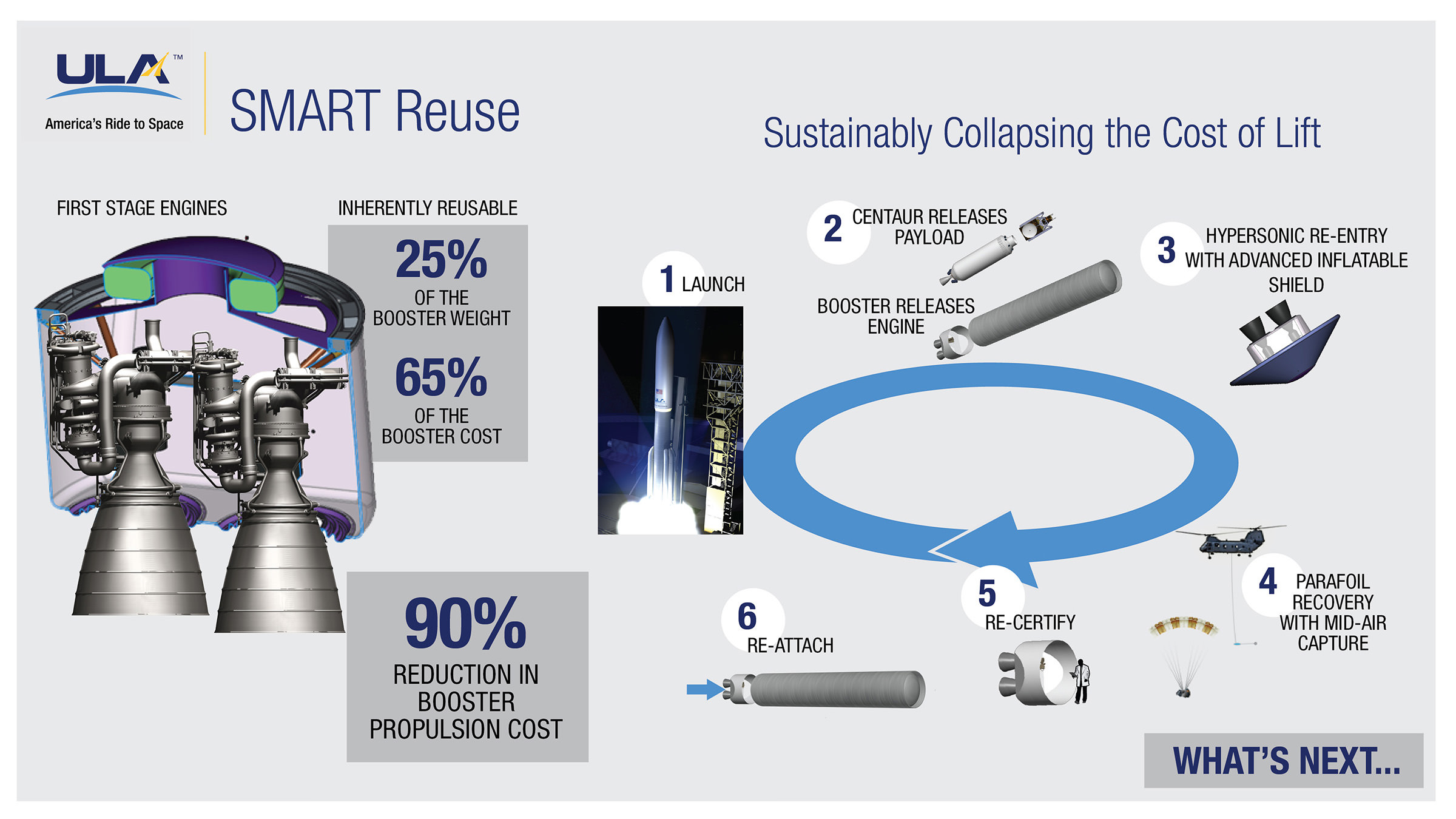

ULA has also already started assembly of the first two Atlas V rockets designated for Starliner at their rocket factory in Decatur, Alabama.

Read my earlier exclusive, in depth one-on-one interviews with Chris Ferguson – America’s last shuttle commander, who now leads Boeings’ CST-100 program; here and here.

Stay tuned here for Ken’s continuing Earth and planetary science and human spaceflight news.