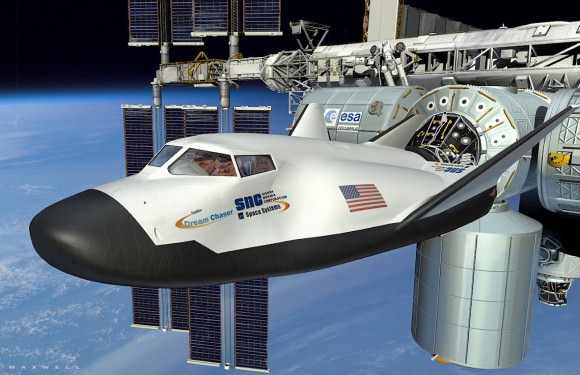

The orbital airframe structure for the first commercial Dream Chaser mini-shuttle that will launch to Earth orbit just over two years from now has been unveiled by Sierra Nevada Corporation (SNC) and program partner Lockheed Martin.

Sierra Nevada is moving forward with plans for Dream Chaser’s first launch and unmanned orbital test flight in November 2016 atop a United Launch Alliance (ULA) Atlas V rocket from Cape Canaveral, Florida.

The winged Dream Chaser is being developed under NASA’s Commercial Crew Program aimed at restoring America’s indigenous human spaceflight access to low Earth orbit and the International Space Station (ISS).

Lockheed Martin is fabricating the structural components for the Dream Chaser’s orbital spacecraft composite structure at the NASA’s Michoud Assembly Facility (MAF) in New Orleans, Louisiana.

MAF has played a long and illustrious history in human space flight dating back to Apollo and also as the site where all the External Tanks for NASA’s space shuttle program were manufactured. Lockheed Martin also builds the pressure vessels for NASA’s deep space Orion crew vehicle at MAF.

Each piece is thoroughly inspected to insure it meets specification and then shipped to Lockheed Martin’s Aeronautics facility in Fort Worth, Texas for integration into the airframe and co-bonded assembly.

Sierra Nevada chose Lockheed Martin for this significant role in building Dream Chaser airframe based on their wealth of aerospace experience and expertise.

The composite airframe structure was recently unveiled at a joint press conference by Sierra Nevada Corporation and Lockheed Martin at the Fort Worth facility.

“As a valued strategic partner on SNC’s Dream Chaser Dream Team, Lockheed Martin is under contract to manufacture Dream Chaser orbital structure airframes,” said Mark N. Sirangelo, corporate vice president of SNC’s Space Systems, in a statement.

“We competitively chose Lockheed Martin because they are a world leader in composite manufacturing, have the infrastructure, resources and quality control needed to support the needs of an orbital vehicle and have a proven track record of leading our nation’s top aviation and aerospace programs. Lockheed Martin’s diverse heritage coupled with their current work on the Orion program adds an extra element of depth and expertise to our program. SNC and Lockheed Martin continue to expand and develop a strong multi-faceted relationship.”

Dream Chaser measures about 29 feet long with a 23 foot wide wing span and is about one third the size of NASA’s space shuttle orbiters.

“We are able to tailor our best manufacturing processes, and our innovative technology from across the corporation to fit the needs of the Dream Chaser program,” said Jim Crocker, vice president of Lockheed Martin’s Space Systems Company Civil Space Line of Business.

Upon completion of the airframe manufacturing at Ft Worth, it will be transported to SNC’s Louisville, Colorado, facility for final integration and assembly.

Lockheed Martin will also process Dream Chaser between orbital flights at the Kennedy Space Center, FL in the recently renamed Neil Armstrong Operations and Checkout Building.

SNC announced in July that they successfully completed and passed a series of risk reduction milestone tests on key flight hardware systems under its Commercial Crew Integrated Capability (CCiCap) agreement with NASA that move the private reusable spacecraft closer to its critical design review (CDR) and first flight.

As a result of completing Milestones 9 and 9a, SNC has now received 92% of its total CCiCAP Phase 1 NASA award of $227.5 million.

“We are on schedule to launch our first orbital flight in November of 2016, which will mark the beginning of the restoration of U.S. crew capability to low-Earth orbit,” says Sirangelo.

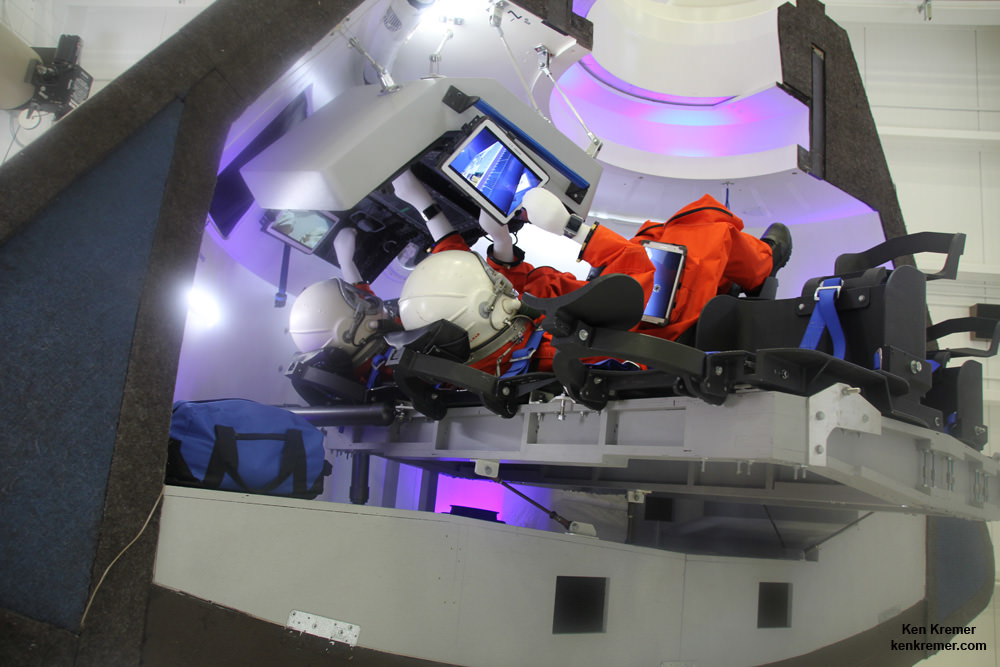

The private Dream Chaser is a reusable lifting-body design spaceship that will carry a mix of cargo and up to a seven crewmembers to the ISS. It will also be able to land on commercial runways anywhere in the world, according to SNC.

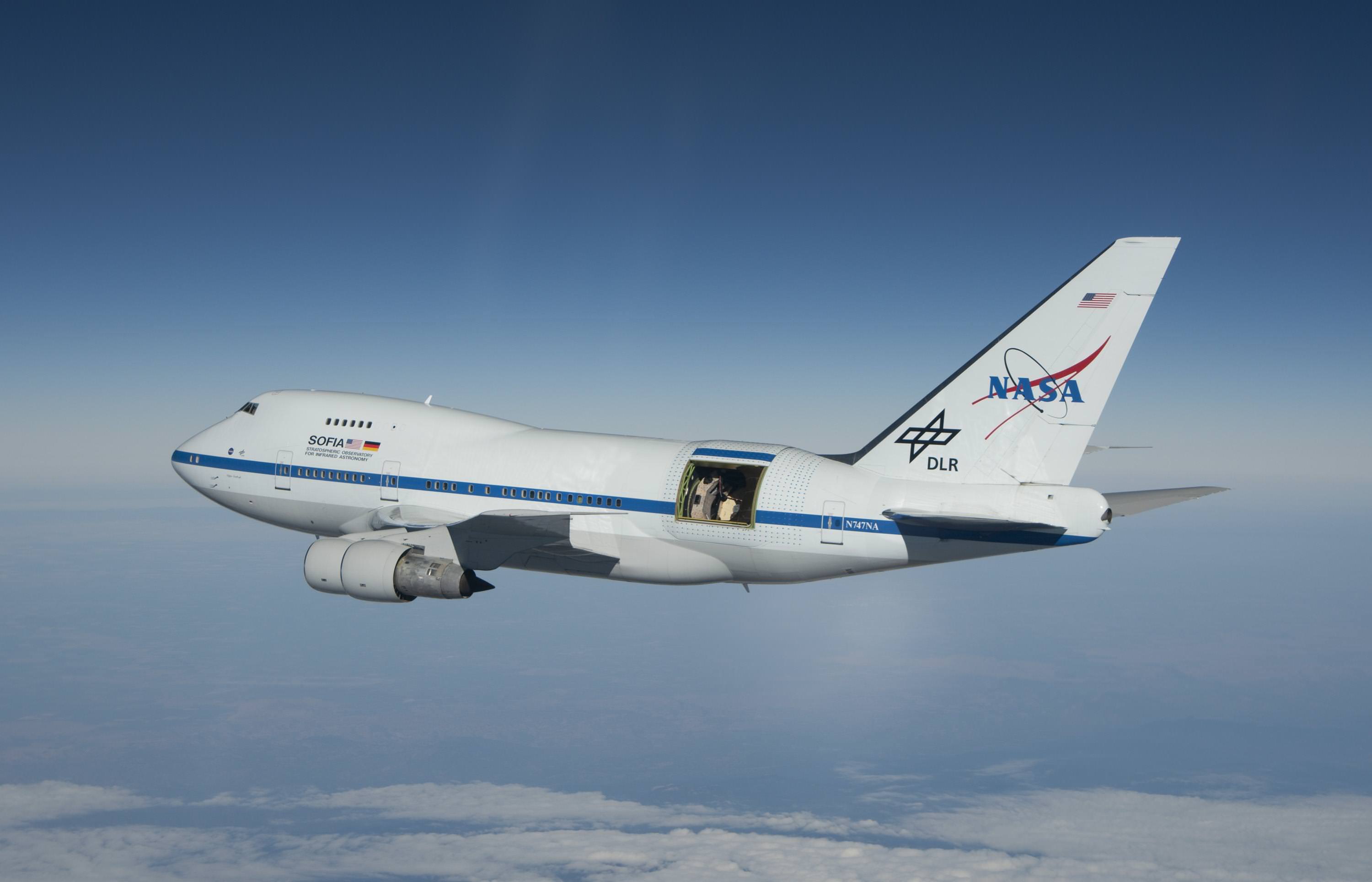

Dream Chaser is among a trio of US private sector manned spaceships being developed with seed money from NASA’s Commercial Crew Program in a public/private partnership to develop a next-generation crew transportation vehicle to ferry astronauts to and from the International Space Station by 2017 – a capability totally lost following the space shuttle’s forced retirement in 2011.

The SpaceX Dragon and Boeing CST-100 ‘space taxis’ are also vying for funding in the next round of contracts to be awarded by NASA around September 2014, NASA officials have told me.

Stay tuned here for Ken’s continuing Sierra Nevada, Boeing, SpaceX, Orbital Sciences, commercial space, Orion, Rosetta, Curiosity, Mars rover, MAVEN, MOM and more planetary and human spaceflight news.