In a complete change of plans from less than three weeks ago, NASA has asked Orbital ATK to switch rockets and launch the firms next Cygnus commercial cargo freighter to the space station on the tried and true Atlas V rather than their own Antares rocket – which just successfully delivered another Cygnus to the orbiting outpost with a hefty stash of science and supplies.

The altered schedule “provides margin flexibility for the entire Antares workforce” Orbital ATK noted in a statement to Universe Today.

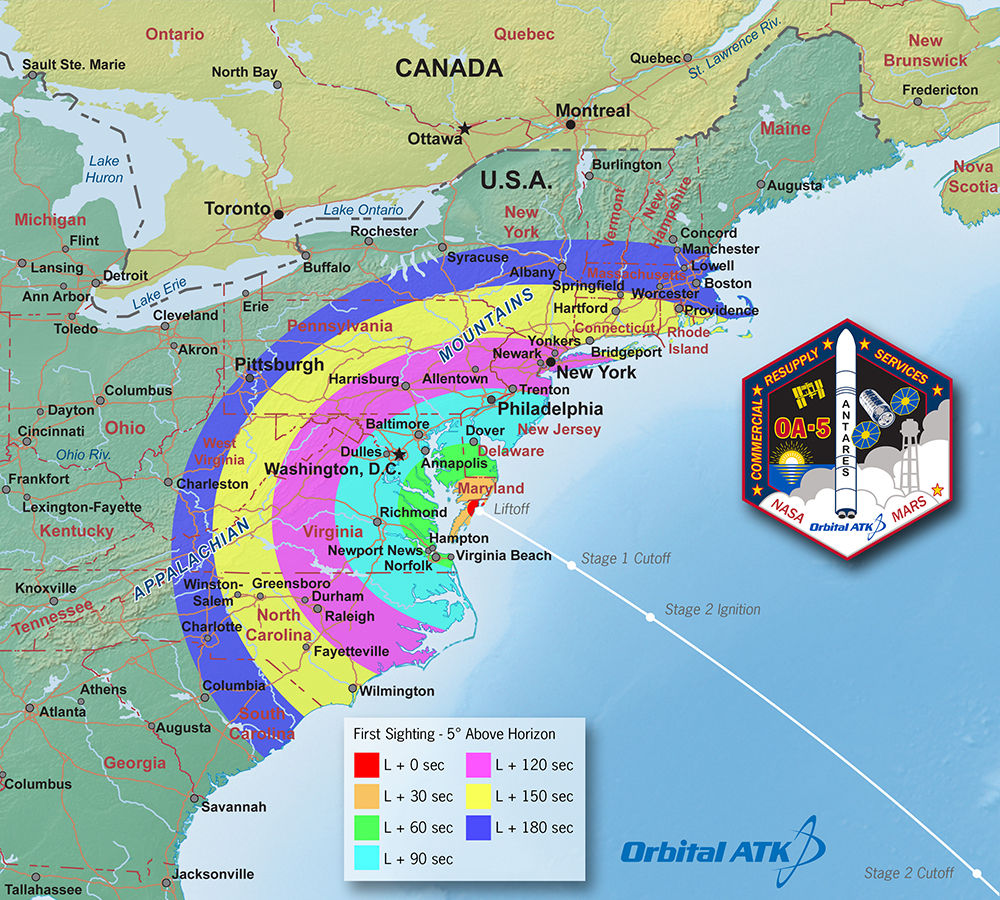

However, the change of events comes as something of a surprise following the spectacularly successful nighttime blastoff of Antares on Oct. 17 with the Cygnus OA-5 resupply ship from the Mid-Atlantic Regional Spaceport at NASA’s Wallops Flight Facility on Virginia’s picturesque Eastern shore – as I reported on from onsite.

At the time, Orbital ATK officials told Universe Today they were working towards efforts for the next Cygnus to launch from Wallops on the OA-7 resupply mission sometime next spring – tentatively in March 2017.

“Following a successful Antares launch for the recent OA-5 Commercial Resupply Services mission and subsequent rendezvous and berthing of the Cygnus spacecraft with the International Space Station, Orbital ATK has responded to NASA’s needs for enhanced schedule assurance for cargo deliveries and maximum capacity of critical supplies to the space station in 2017 by once again partnering with United Launch Alliance to launch Cygnus aboard an Atlas V for the upcoming OA-7 mission in the spring timeframe,” Orbital ATK said in a statement to Universe Today.

“We anticipate the earliest we may need a NASA commercial resupply mission is early 2017. We mutually agreed with Orbital ATK to use an Atlas V for the company’s seventh contracted cargo resupply mission to the space station in the spring. We will provide additional details at a later date,” NASA HQ public affairs told Universe Today for this story.

The ULA Atlas V would launch from Space Launch Complex-41 on Cape Canaveral Air Force Station.

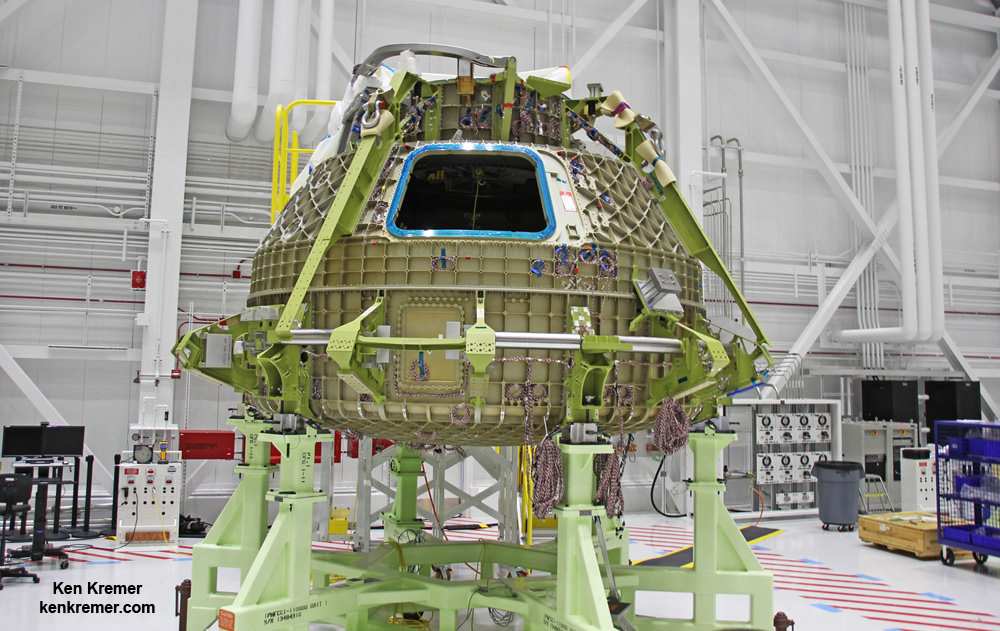

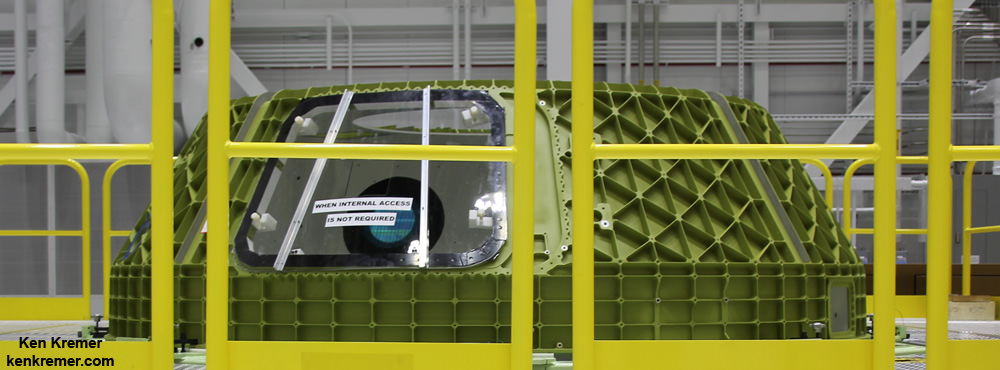

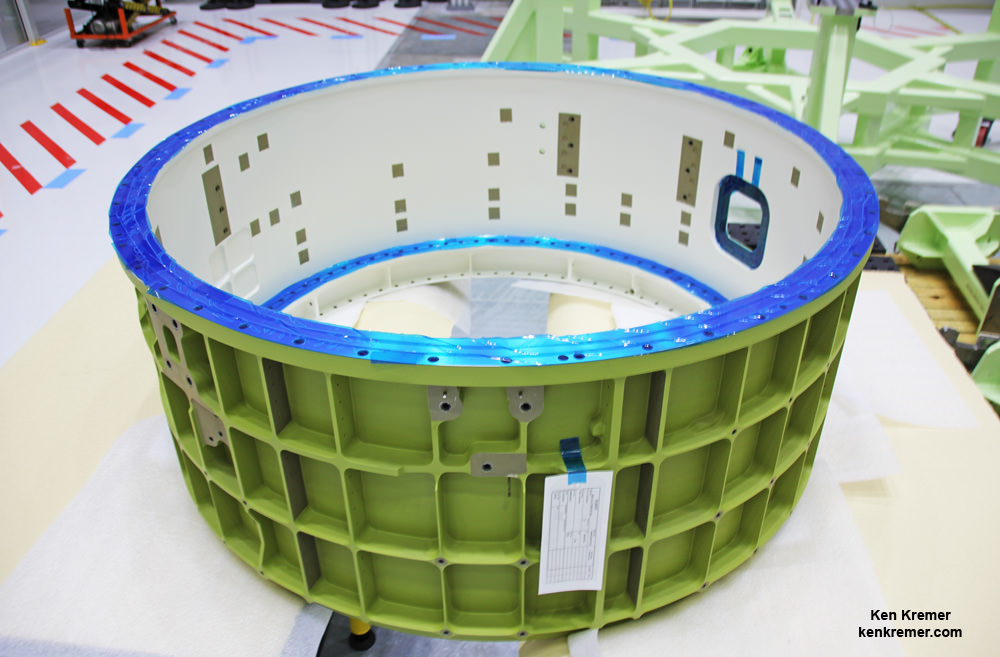

Cygnus OA-7 will be processed and loaded at NASA’s Kennedy Space Center in Florida for later integration with the Atlas V.

When Cygnus launches on Atlas from KSC it can carry roughly over 300 pounds more to orbit vs. using Antares from Virginia.

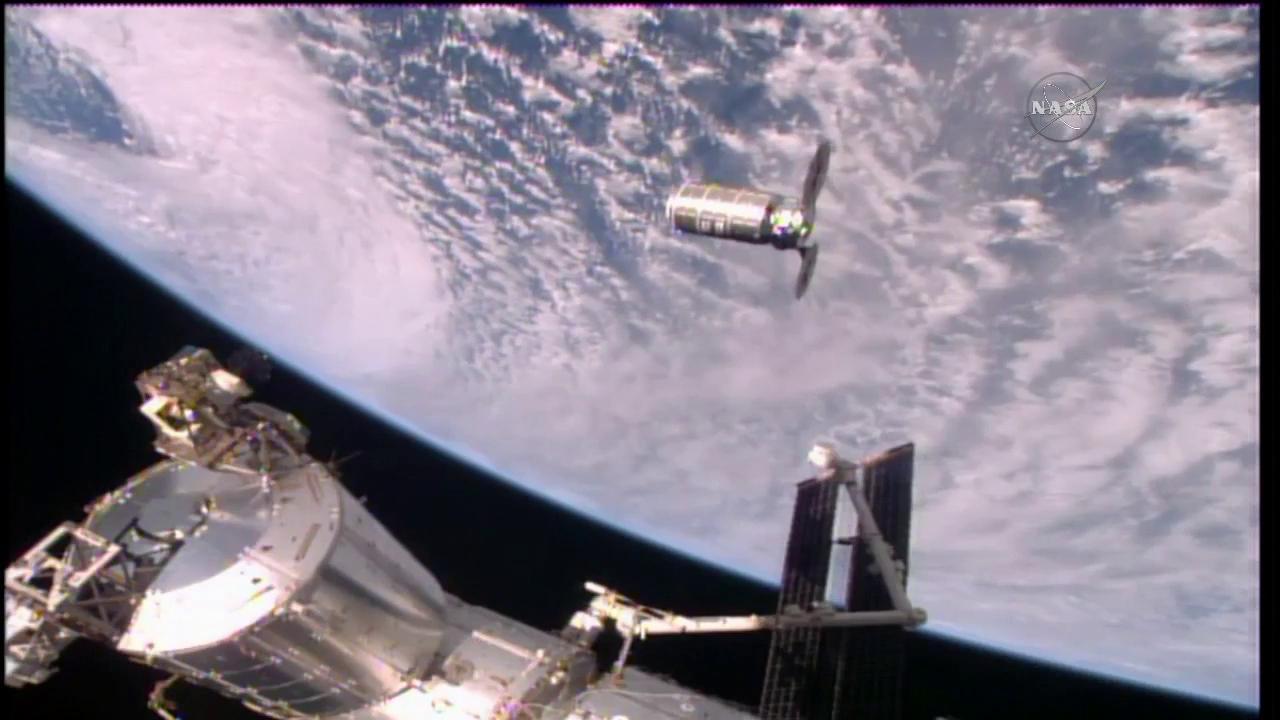

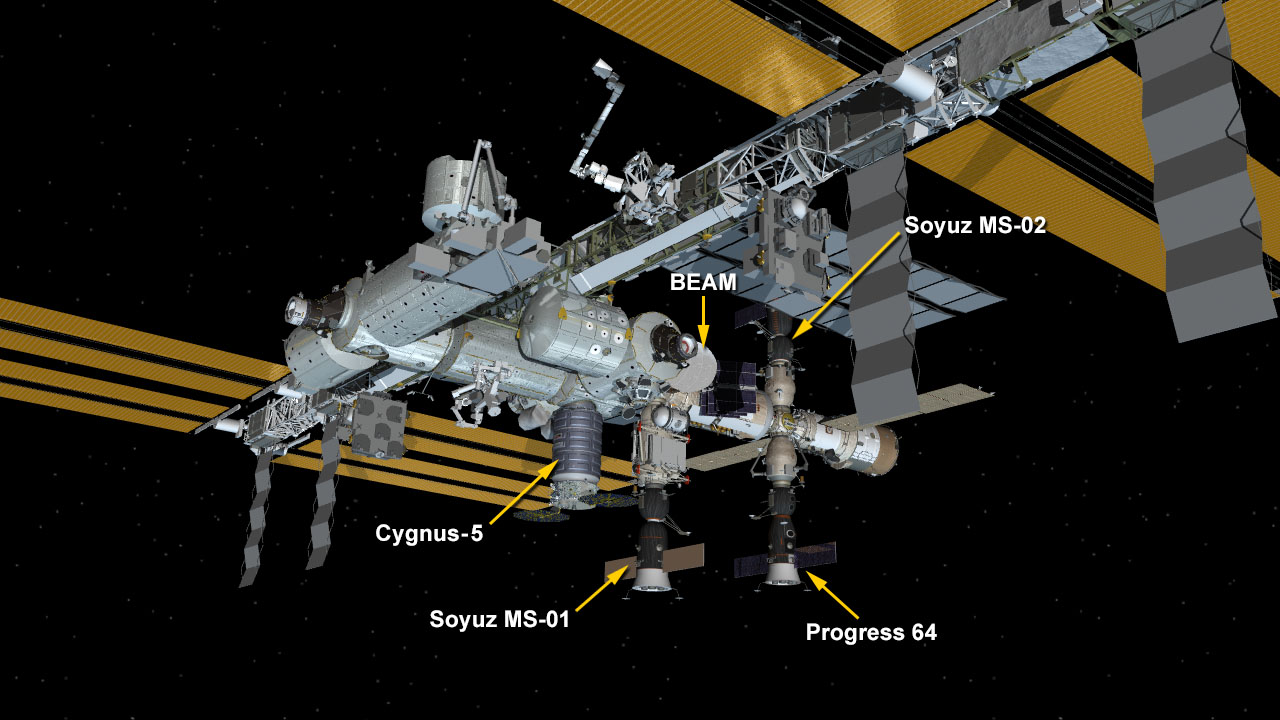

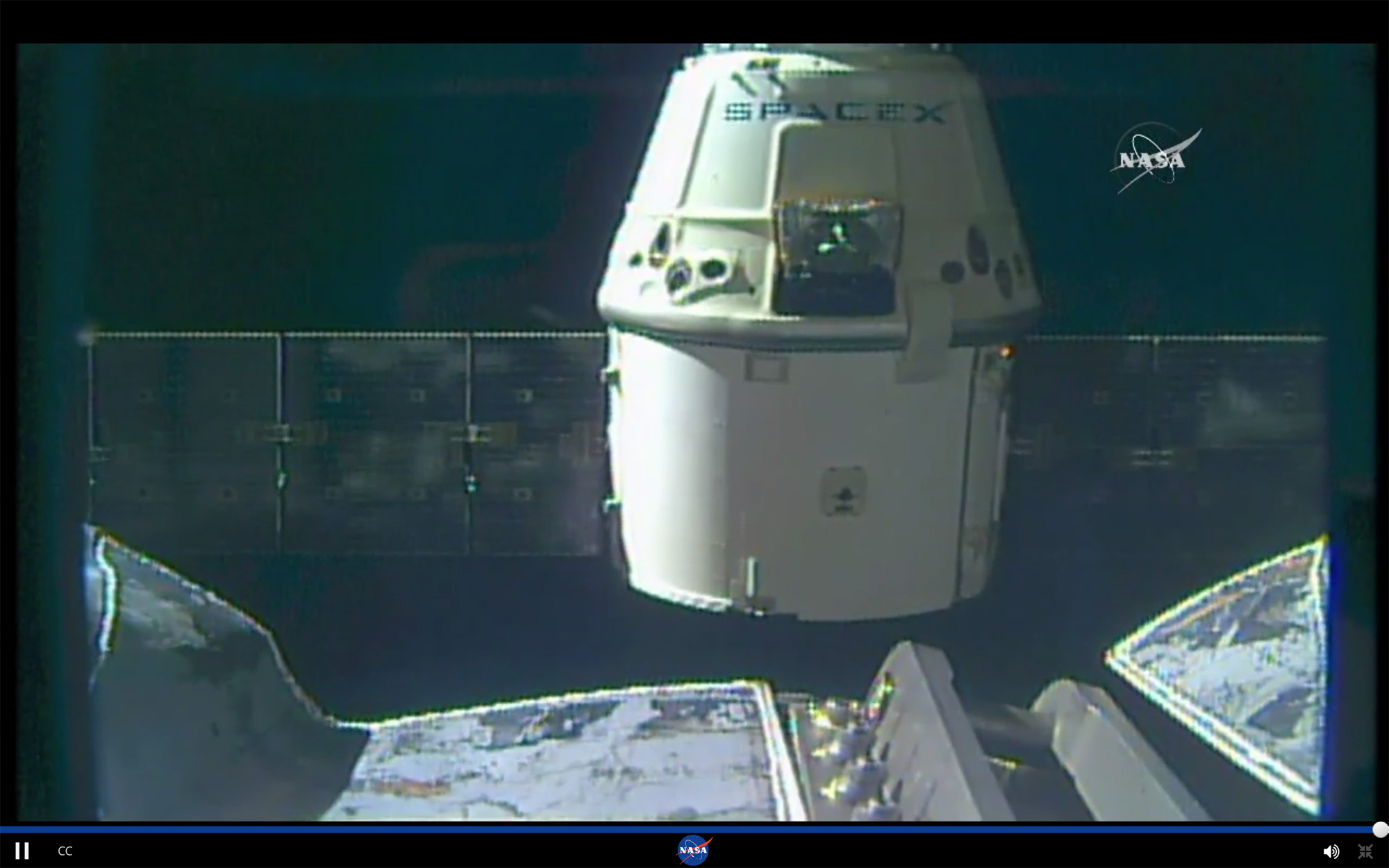

The Cygnus OA-5 spaceship is currently still berthed at the million pound station and carried about 5100 pounds to orbit.

Thus the ISS is in good shape overall at this time from a supplies standpoint.

“Supplies and research investigations are at good levels aboard the International Space Station. In addition to Orbital ATK’s recent successful commercial resupply services mission to station in October, a Russian Progress and Japanese HTV will carry additional cargo to the orbiting laboratory before the end of the year,” NASA public affairs elaborated for this story.

Last month’s ‘Return to Flight’ liftoff of the upgraded Antares took place two years after its catastrophic failure moments after launch on October 28, 2014 with another Cygnus cargo ship bound for the International Space Station (ISS) that was destroyed along with all its precious contents.

And that may be the rub, along with the fact that launches by NASA’s other Commercial Resupply Services (CRS) provider – namely SpaceX – are on hold due to the catastrophic launch pad failure on Sept. 1.

Thus it’s not clear at this time when SpaceX can resume launching their Dragon cargo ships to the ISS.

NASA must have a robust and steady train of cargo ships flying to the ISS to keep it fully operational and stocked with research and provisions for the international crews to maximize the stations science output.

“NASA is continuously working with all our partners on range availability, space station traffic and other factors to ensure we operate station in a safe and effective way as we use it for preparing for longer duration missions farther into the solar system,” NASA PAO told me.

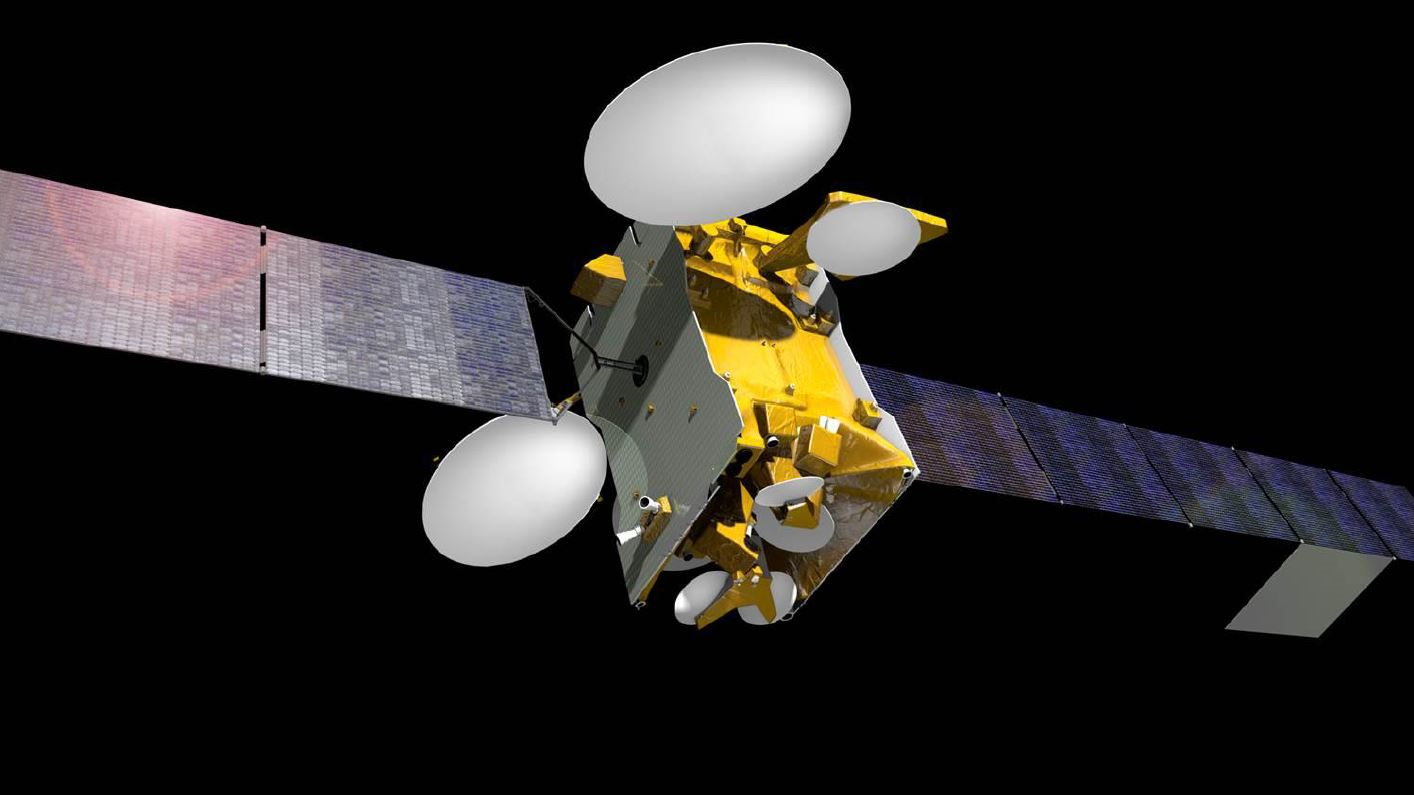

The Atlas V built by competitor United Launch Alliance (ULA) enjoys a 100% record of launch success and was recently employed by Orbital ATK to launch a pair of Cygnus vessels to the International Space Station in the past year – in Dec. 2015 on the OA-4 mission and March 2016 on the OA-6 mission.

Orbital ATK contracted ULA to launch Cygnus spacecraft to the ISS as an interim measure to fulfill their obligations to NASA to keep the station fully operational.

Orbital ATK Vice President Frank Culbertson had previously told me that Orbital ATK could readily launch future Cygnus spaceships on the ULA Atlas V again, if the need arose.

Seeking some near term launch stability NASA has apparently decided that that need has now arisen.

Both Atlas/Cygnus cargo missions went off without a hitch and provide a ready and working template for the upcoming OA-7 cargo ship to be processed again at KSC and launched from Cape Canaveral in the spring of 2017.

Orbital ATK says that follow on Cygnus craft will again return to the Antares rocket for Virginia launches later in 2017.

“Orbital ATK’s remaining missions to be conducted in 2017 and 2018 under the CRS-1 contract will launch aboard the company’s Antares rockets from NASA Wallops Flight Facility in Virginia.”

Altogether a trio of Cygnus vessels might launch in 2017.

“The company will be ready to support three cargo resupply missions to the station next year, and will work with NASA to finalize the flight schedule,” the company said.

“The schedule provides margin flexibility for the entire Antares workforce, who worked tirelessly for the past several months to prepare and successfully launch the upgraded rocket from Wallops Island on the OA-5 mission.”

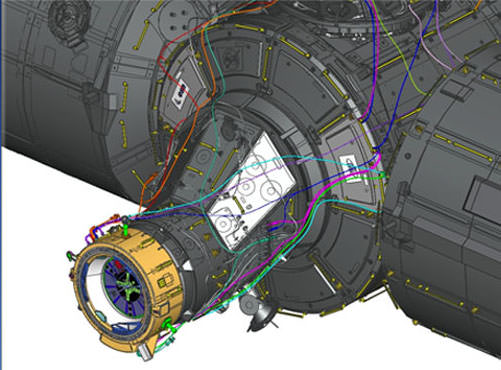

Cygnus was designed from the start to launch on a variety of launch vehicles – in addition to Antares.

“This plan also allows NASA to again capitalize on the operational flexibility built into Orbital ATK’s Cygnus spacecraft to assure the space station receives a steady and uninterrupted flow of vital supplies, equipment and scientific experiments.”

Under the Commercial Resupply Services (CRS) contract with NASA, Orbital ATK will deliver approximately 28,700 kilograms of cargo to the space station. OA-5 is the sixth of these missions.

It is not clear at this time who will shoulder the added cost of launching Cygnus OA-7 on Atlas instead of Antares.

Watch for Ken’s Antares/Atlas/Cygnus mission and launch reporting. He was reporting from on site at NASA’s Wallops Flight Facility, VA during the OA-5 launch campaign and previously from KSC for the OA-4 and OA-6 liftoffs.

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news.