An international trio of astronauts and cosmonauts representing the United States, Russia and Japan blasted off in the early morning Kazakh hours today, July 7, for a new mission of science and discovery on the International Space Station (ISS).

The three person crew of two men and one woman launched flawlessly into picture perfect skies from the Baikonur Cosmodrome in Kazakhstan at 9:36 p.m. EDT Wednesday, July 6 (7:36 a.m. Baikonur time, July 7), and in a brand new version of the Russian Soyuz capsule that has been significantly upgraded and modified.

The launch of the Soyuz MS-01 spacecraft was carried live on NASA TV starting approximately an hour before the usual on time liftoff from Baikonur. The three stage Soyuz booster generates 930,000 pounds of liftoff thrust.

The trio comprises Kate Rubins of NASA, Soyuz Commander Anatoly Ivanishin of the Russian space agency Roscosmos and Takuya Onishi of the Japan Aerospace Exploration Agency on the Expedition 48/49 mission.

They safely reached orbit at about 9:46 p.m. after the eight minute climb delivered them to the preliminary orbit of 143 x 118 mi. The Soyuz separated from the third stage and the solar arrays deployed as planned. NASA’s Kate Rubins was strapped into the left seat, Ivanishin in the center and Onishi on the right.

And precisely because it’s a heavily modified Soyuz, they will take the slow road to the ISS.

The crew will spend the next two days and 34 Earth orbits inside in order to fully check out and test the upgraded Soyuz spacecraft systems.

That’s in contrast to missions in recent years that took a vastly sped up 4 orbit 6 hour route to the space station.

Three carefully choreographed orbital adjustment burns will raise the orbit and propel the crew to the ISS over the next 2 days.

They expect to rendezvous and dock at the space station’s Russian Rassvet module at 12:12 a.m. EDT Saturday, July 9. After conducting leak and safety check they expect to open the hatch to the ISS at about 2:50 a.m. Saturday, July 9.

You can watch all the hatch opening action live on NASA TV with coverage starting at 2:30 a.m.

They will spend about four months at the orbiting lab complex conducting more than 250 science investigations in fields such as biology, Earth science, human research, physical sciences, and technology development.

With the arrival of Rubins, Ivanishin and Onishi, the station is beefed up to its normal six person crew complement.

Rubins is on her rookie space mission. She holds a bachelor’s degree in molecular biology and a doctorate in cancer biology which will be a big focus of her space station research activities.

The new trio will join Expedition 48 Commander Jeff Williams of NASA and Flight Engineers Oleg Skripochka and Alexey Ovchinin of Roscosmos.

The Expedition 48 crew members will spend four months contributing to more than 250 experiments in fields such as biology, Earth science, human research, physical sciences and technology development.

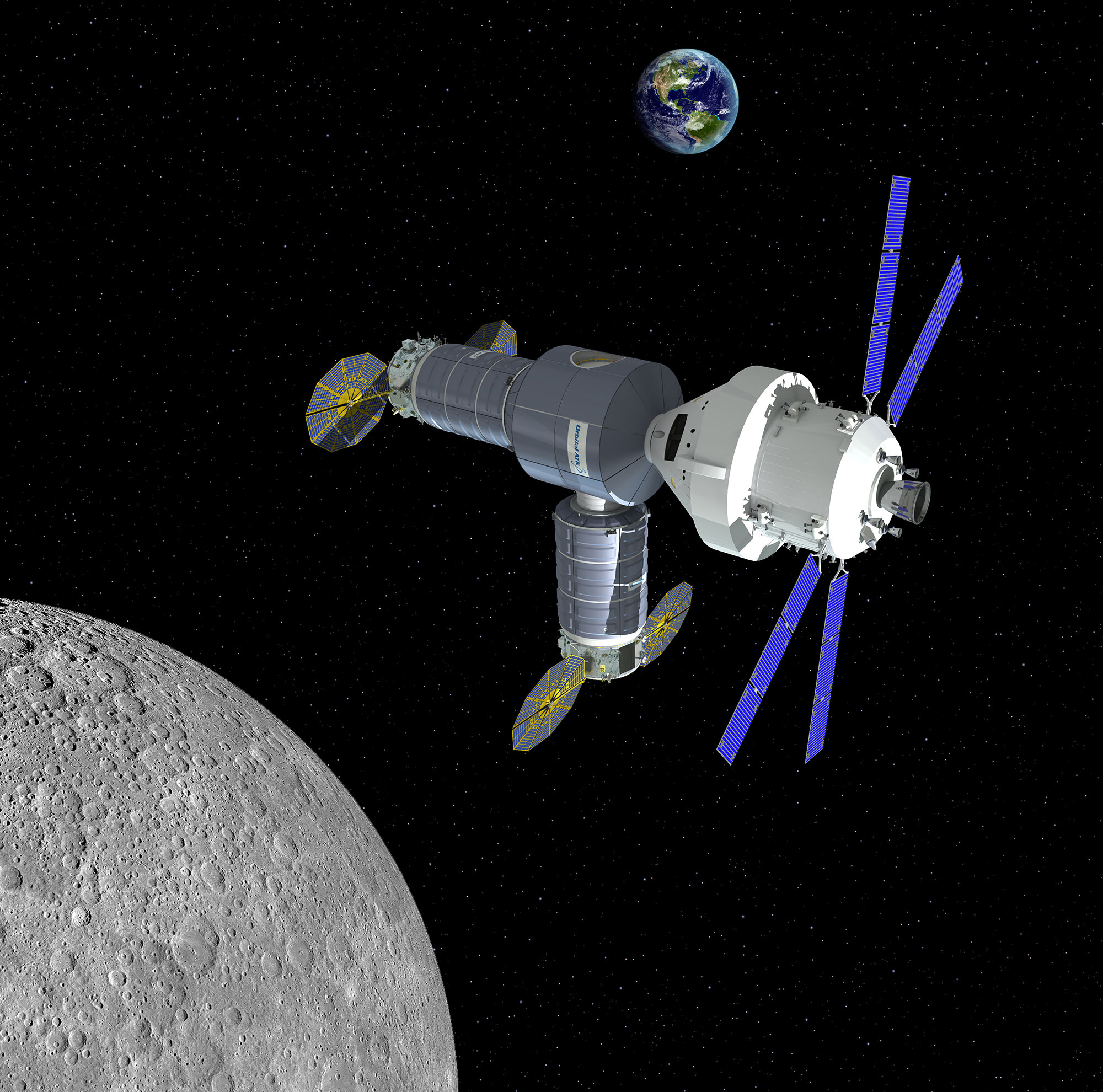

“The approximately 250 research investigations and technology demonstrations – not possible on Earth – will advance scientific knowledge of Earth, space, physical, and biological sciences. Science conducted on the space station continues to yield benefits for humanity and will enable future long-duration human and robotic exploration into deep space, including the agency’s Journey to Mars,” says NASA.

The newly upgraded Soyuz offers increased reliability and enhanced performance. Many changes were instituted including enhanced structural performance to minimize chances of meteorite penetration. Engineers also added a fifth battery for more power and storage capacity. The solar arrays are also about one square meter larger and the efficiency of the solar cells increased about 2 percent.

Also a more modern command and telemetry system to interact with a new series of new Russian communications satellites that will offer greatly increased the coverage by ground control from only about 20 minutes per orbit up to from 45 to 90% of orbital coverage.

A phased array antenna was also added with increased UHF radio capability in the Soyuz descent module that now also include a GPS system to improve search and rescue possibilities.

The newly upgraded KURS rendezvous radar system will weigh less, use less power and overall will be less complicated. For example it doesn’t have to be moved out of the way before docking. Weighs less and uses less power.

New approach and attitude control thrusters were installed. The new configuration uses 28 thrusters with a redundant thruster for each one – thus two fully redundant manifolds of 28 thrusters each.

All of these modification were tested out on the last two progress vehicles.

Multiple unmanned cargo ships carrying tons of essential supplies and science experiments are also scheduled to arrive from Russia, the US and Japan over the next few months.

A SpaceX Dragon could launch as soon as July 18 and an Orbital ATK Cygnus could follow in August.

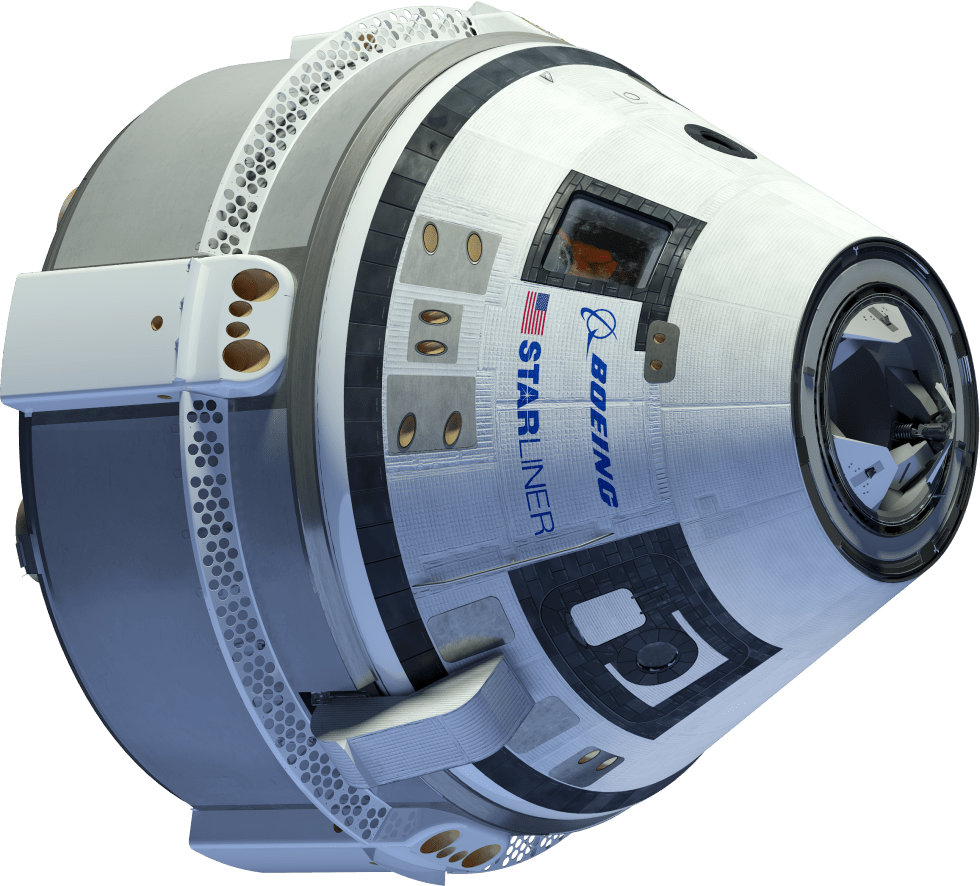

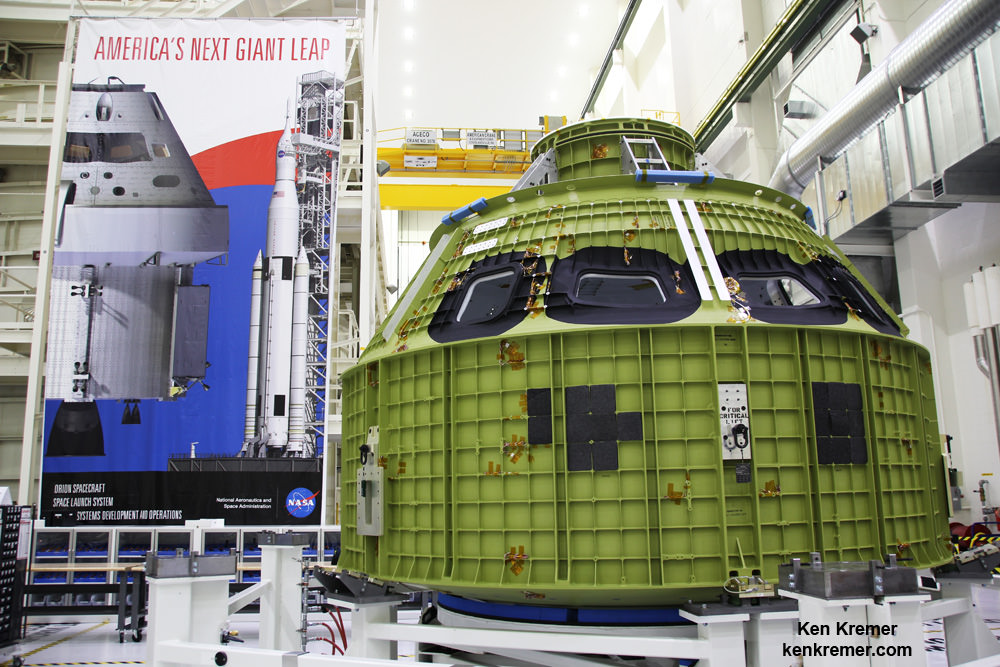

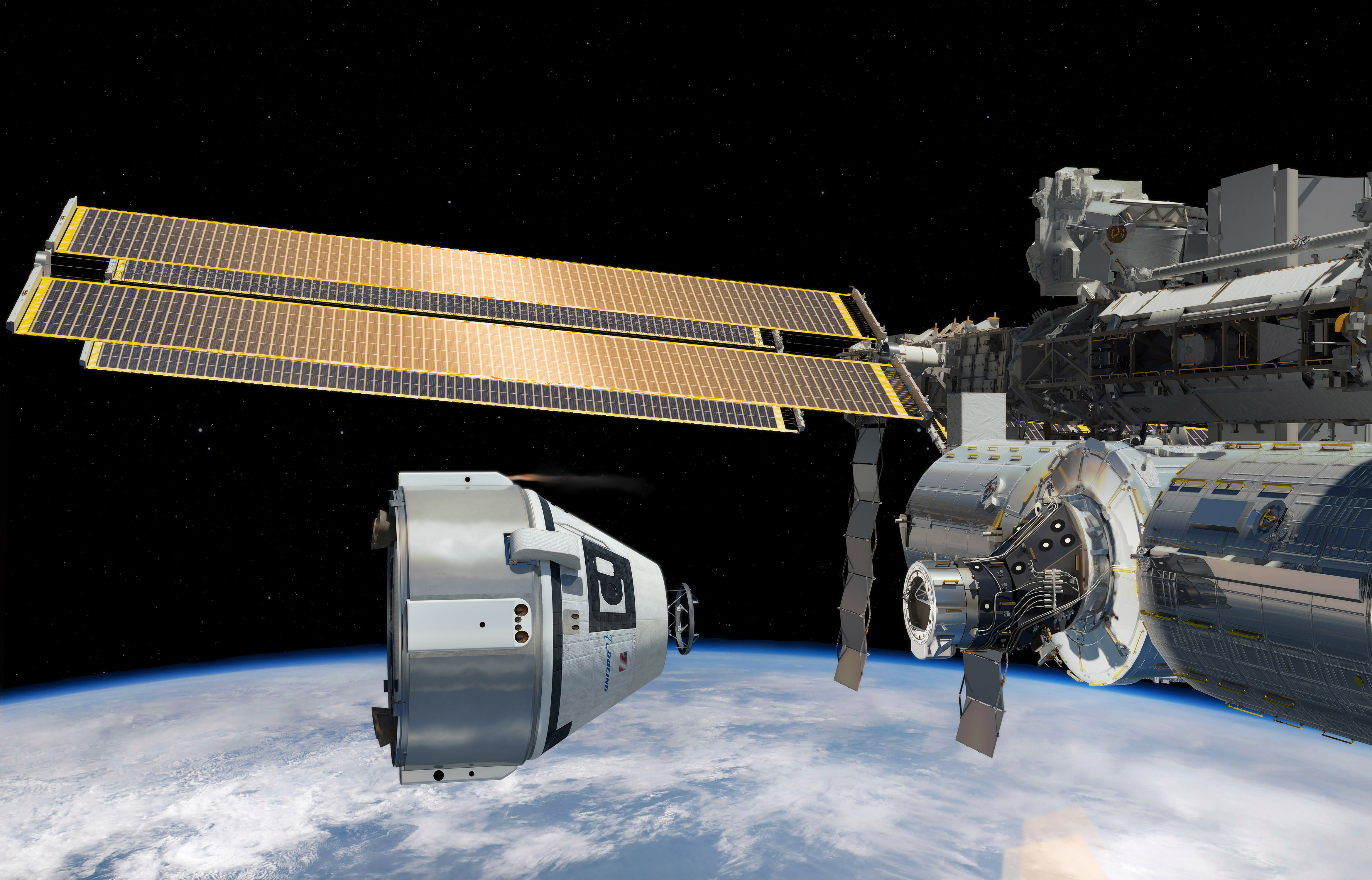

The Dragon CRS-9 mission is slated to deliver the station’s first International docking adapter (IDA) to accommodate the future arrival of U.S. commercial crew spacecraft, including the Boeing built Starliner and SpaceX built Crew Dragon.

A Japanese HTV cargo craft will carry lithium ion batteries to replace the nickel-hydrogen batteries currently used on station to store electrical energy generated by the station’s huge rotating solar arrays.

Two Russian Progress craft with many tons of supplies are also scheduled to arrive.

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news.