So can we get off of Earth already and start building bases on the Moon or an asteroid? As highlighted in a recent Office of Science and Technology Policy blog post, one way to do that quickly could be to use resources on site. But how do we even get started? Can we afford to do it now, in this tough economic climate?

Universe Today spoke with Philip Metzger, a former senior research physicist at NASA’s Kennedy Space Center, who has explored this subject extensively on his website and in published papers. He argues that to do space this way would be similar to how the pilgrims explored North America. In the first of a three-part series, he outlines the rationale and the first steps to making it there.

UT: It’s been said that using resources on the Moon, Mars or asteroids will be cheaper than transporting everything from Earth. At the same time, there are inherent startup costs in terms of developing technology to do this extraction and also sending this equipment over there, among other things. How do we reconcile these two realities?

PM: Space industry will have a tremendous payback, but it will be costly to start. Several years ago I was frustrated because I didn’t think that commercial interests alone would be enough to get it fully started within our generation, so I asked the question, can we find an inexpensive way for the governments of the world (or philanthropists or others who may not have an immediate commercial interest) to get it started simply because of the societal benefits it will bring? That’s why my colleagues and I wrote the paper “Affordable Rapid Bootstrapping of Space Industry and Solar System Civilization.”

We are advocating a bootstrapping approach because it helps solve the problem of the high startup cost and it enables humanity to start reaping the benefits quickly, since we need them quickly. A bootstrapping approach works like this: instead of building all the hardware on Earth and sending it into space ready to start manufacturing things, we can send a reduced set of hardware into space and make only a little bit of what we need. We can send the rest of the manufactured parts from Earth and combine them with what we made in space. Over time we keep doing this until we evolve up to a full manufacturing capability in space.

This is how colonies on Earth built themselves up until eventually they were able to match the industry of their homelands. The pilgrims, for example, didn’t bring entire factories from Europe over on the Mayflower. Now it took hundreds of years to build up American industry, but with robotics and advanced manufacturing and with some intentionality we can get it done much more quickly at still an affordable price. We have done some rudimentary modeling of this bootstrapping approach and it looks as though it would be a small part of our annual space budget and it could establish the industry within just decades.

What I think is even more important than the cost is that with a bootstrapping approach we can get started right away. We don’t need to complete the entire design and development up front. It also spreads the cost over time so the annual expenses are very low. And it allows us time to evolve our strategy, to figure out what works and what will have more immediate economic payback, as we go along. Many people are looking for the immediate ways to get a payback in space, and there are some great ideas and I am sure they will be successful. One example is to set up a mining operation that refuels communication satellites in geosynchronous orbit. These sorts of activities will contribute to, and will benefit from, the effort to start industry in space, and they will generate revenue to fund their portion of the effort.

UT: Why do you feel the Moon is a good spot to start operations? What would be some activities to start with there? How do we move from there into the rest of the solar system?

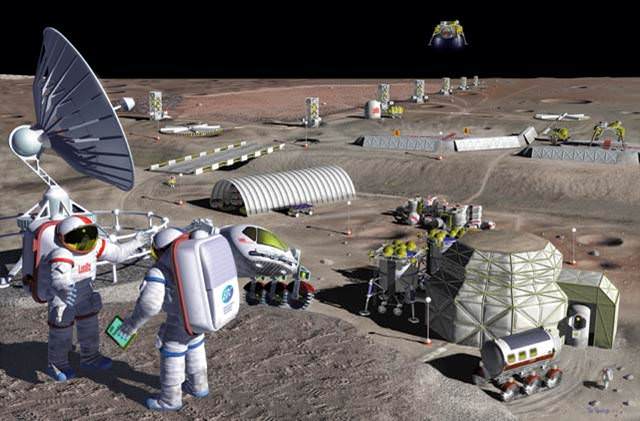

When my colleagues and I wrote the paper, we were focused on the Moon in part because that was during NASA’s Constellation program to establish a lunar outpost. However, it is equally possible to use near-Earth asteroids to start this space industry, or to use both. In any case, we need to start space industry close to the Earth. That will keep transportation costs low during the startup. It also enables us to work with much shorter time delay in the radio communications, which is important in the early stages before robotics become sufficiently automated. Ideally the industry will be fully automated; we want robots to prepare the way for humans to follow.

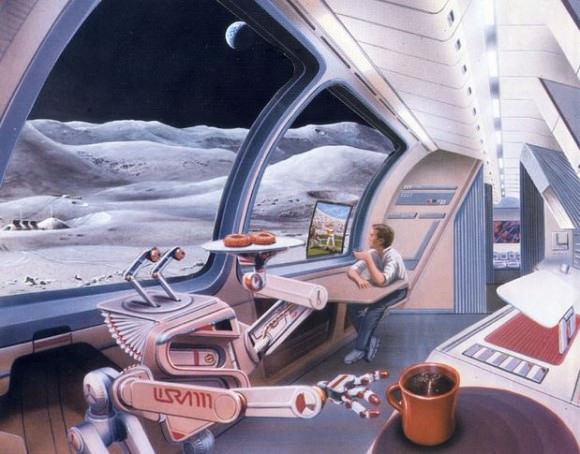

However, if we think we will need humans during initial start-up of the industry – for example, to fix or troubleshoot broken hardware, or to do complex tasks that robots can’t yet do – then starting near Earth becomes even more important. It turns out that both the Moon and asteroids are excellent places to start industry. We now know that they have abundant water, minerals from which metals can be refined, carbon for making plastics, and so on. I am glad there are companies planning to develop mining in both locations so we can see what works best.

Another reason to start industry close to Earth is so it can have an early economic payback. In the end, when everything including spaceships and refueling depots are made in space by autonomous robotics, then industry becomes self-sustaining and it will pay us back inestimably for no further cost. Getting to that point requires some serious investment, though, and it will be easier to make the investments if we are getting something back. So what kinds of payback can it give us in the near-term? I keep a list of ideas how to make money in space, and there are about 19 items on the list, some crazy and some not so crazy. A few of the serious ideas include: space tourism; making and selling propellants to NASA for exploration and science missions; returning metals like platinum for sale on Earth; and manufacturing spare parts for other activities in space.

Some of the initial things we will do on the Moon or asteroids includes perfecting the low-gravity mining techniques, learning how to make solar cells out of regolith, and learning how to extract useful metals from minerals that would not be considered “ore” here on Earth. All of these are possible and require only modest investment to make them work.

It will take decades of effort to make space industry self-sustaining. Maybe 2 decades if we get started right away and work steadily, or maybe 5 decades if we have a lower level of funding. But if robotics advance as fast as the roboticists are expecting, soon there will be no manufacturing task a robot cannot do. When that day arrives, and we have set up a complete supply chain in space, then it will be an easy thing to send sets of hardware to the main asteroid belt to begin mining and manufacturing where there are billions of times the resources more than what we have on Earth.

Then, the industry could build landing craft to take equipment to the surface of Mars where it can build cities and eventually even terraform the planet. When we have machines that can use local resources to perform work and build copies of themselves, then they can perform the same role on dry worlds that biological life has performed here on our wet Earth. They can transform the environment and become the food chain so those worlds will be places where humanity can work and live. I realize this sounds too ambitious, but 20 to 50 years of technology growth is going to make a huge difference, and we are only talking about manufacturing – not rocket science — and that is something that we are already quite good at here on Earth. With just a little extrapolation into the future it is not a crazy idea.

UT: What are the main pieces of equipment and robotics that we need up there to accomplish these objectives?

PM: There is an interesting open source project developing what they call the “Global Village Construction Set.” It is 50 machines that will be capable of restarting civilization. It includes things like a windmill, a backhoe, and a 3D printer. What we need is the equivalent “Lunar/Asteroid Village Construction Set.”

A study was done by NASA in 1980 to determine what set of machines are needed in factories on the Moon to build 80% of their own parts. The other 20% would need to be supplied constantly from Earth. In our paper we argued that we can start at much less than 80% closure, making it more affordable and allowing us to start today, but the system should evolve until it reaches 100% closure. So the first set of hardware might make crude solar cells, metal, 3D printed metal parts, and rocket propellants.

Having just that will allow us to make a significant mass of the next generation of hardware as well as support the transportation network. Over time, we want to develop an entire supply chain which would be more extensive than just 50 different types of machines. But before we put anything in space we will want to test them in rugged locations here on Earth, and in the process we will discover what set of machines makes the most sense for the first generation. The idea is to learn as we go, so we can get started right away.

This is the first in a three-part series about building a space base. Tomorrow: How much money would it take? Day after tomorrow: Making remote robots smart.