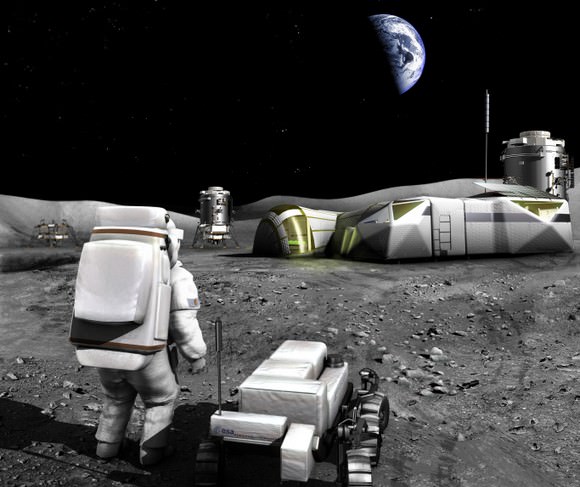

How much would it cost to establish a space base close to Earth, say on the Moon or an asteroid? To find out, Universe Today spoke with Philip Metzger, a former senior research physicist at NASA’s Kennedy Space Center, who has explored this subject extensively on his website and in published papers.

Yesterday, Metzger outlined the rationale for establishing a base in the first place, while today he focuses on the cost.

UT: Your 2012 paper specifically talks about how much development is needed on the Moon to make the industry “self-sustaining and expanding”, but left out the cost of getting the technology ready and of their ongoing operation. Why did you leave this assessment until later? How can we get a complete picture of the costs?

PM: As we stated at the start of the paper, our analysis was very crude and was intended only to garner interest in the topic so that others might join us in doing a more complete, more realistic analysis. The interest has grown faster than I expected, so maybe we will start to see these analyses happening now including cost estimates. Previous analyses talked about building entire factories and sending them into space. The main contribution of our initial paper was to point out that there is this bootstrapping strategy that has not been discussed previously, and we argued that it makes more sense. It will result in a much smaller mass of hardware launched into space, and it will allow us to get started right away so that we can figure out how to make the equipment work as we go along.

Trying to design up front everything in a supply chain for space is impossible. Even if we got the budget for it and gave it a try, we would discover that it wouldn’t work when we sent it into the extraterrestrial environments. There are too many things that could go wrong. Evolving it in stages will allow us to work out the bugs as we develop it in stages. So the paper was arguing for the community to take a look into this new strategy for space industry.

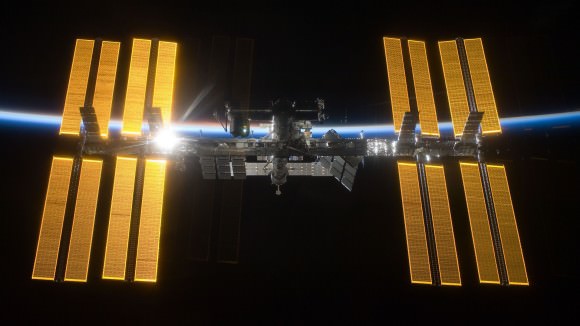

Now, having said that, I can still give you a very crude cost estimate if you want one. Our model shows a total of about 41 tons of hardware being launched to the Moon, but that results in 100,000 tons of hardware when we include what was made there along the way. If 41 tons turns out to be correct, then let’s take 41% of the cost of the International Space Station as a crude estimate, because that has a mass of 100 tons and we can roughly estimate that a ton of space hardware costs about the same in every program. Then let’s multiply by four because it takes four tons of mass launched to low Earth orbit to land one ton on the Moon.

That may be an over-estimate, because the biggest cost of the International Space Station was the labor to design, build, assemble, and test before launch, including the cost of operating the space shuttle fleet. But the hardware for space industry includes many copies of the same parts so design costs should be lower, and since human lives will not be at stake they don’t need to be as reliable. As discussed in the paper, the launch costs will also be much reduced with the new launch systems coming on line.

Furthermore, the cost can be divided by 3.5 according to the crude modeling, because 41 tons is needed only if the industry is making copies of itself as fast as it can. If we slow it down to making just one copy of the industry along the way as it is evolving, then only 12 tons of hardware needs to be sent to the Moon. Now that gives us an estimate of the total cost over the entire bootstrapping period, so if we take 20 or 30 or 40 years to accomplish it, then divide by that amount to get the annual cost. You end up with a number that is a minority fraction of NASA’s annual budget, and a miniscule fraction of the total U.S. federal budget, and even tinier fraction of the US gross domestic product, and an utterly insignificant cost per human being in the developed nations of the Earth.

Even if we are off by a factor of 10 or more, it is something we can afford to start doing today. And this doesn’t account for the economic payback we will be getting while starting space industry. There will be intermediate ways to get a payback, such as refueling communications satellites and enabling new scientific activities. The entire cost needn’t be carried by taxpayers, either. It can be funded in part by commercial interests, and in part by students and others taking part in robotics contests. Perhaps we can arrange shares of ownership in space industry for people who volunteer time developing technologies and doing other tasks like teleoperating robots on the Moon. Call that “telepioneering.”

Perhaps most importantly, the technologies we will be developing – advanced robotics and manufacturing – are the same things we want to be developing here on Earth for the sake of our economy, anyway. So it is a no-brainer to do this! There are also intangible benefits: giving students enthusiasm to excel in their education, focusing the efforts of the maker community to contribute tangibly to our technological and economic growth, and renewing the zeitgeist of our culture. Civilizations fall when they become old and tired, when their enthusiasm is spent and they stop believing in the inherent value of what they do. Do we want a positive, enthusiastic world working together for the greater good? Here it is.

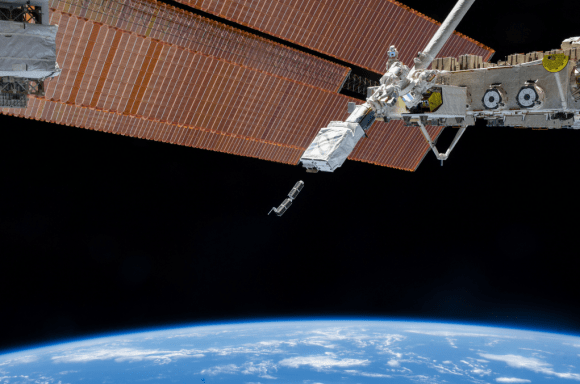

UT: We now have smaller computers and the ability to launch CubeSats or smaller accompanying satellites on rocket launches, something that wasn’t available a few decades ago. Does this reduce the costs of sending materials to the Moon for the purposes of what we want to do there?

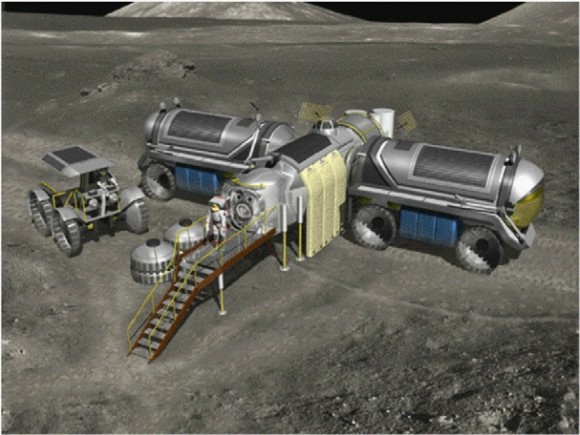

Most of the papers about starting the space industry are from the 1980’s and 1990’s because that is when most of the investigations were performed, and there hasn’t been funding to continue their work in recent decades. Indeed, changes in technology since then have been game-changing! Back then some studies were saying that a colony would need to support 10,000 humans in space to do manufacturing tasks before it could make a profit and become economically self-sustaining. Now because of the growth of robotics we think we can do it with zero humans, which drastically cuts the cost.

The most complete study of space industry was the 1980 Summer Study at the Ames Research Center. They were the first to discuss the vision of having space industry fully robotic. They estimated mining robots would need to be made with several tons of mass. More recently, we have actually built lunar mining robots at the Swamp Works at the Kennedy Space Center and they are about one tenth of a ton, each. So we have demonstrated a mass reduction of more than 10 times.

But this added sophistication will be harder to manufacture on the Moon. Early generations will not be able to make the lightweight metal alloys or the electronics packages. That will require a more complex supply chain. The early generations of space industry should not aim to make things better; they should aim to make things easier to make. “Appropriate Technology” will be the goal. As the supply chain evolves, eventually it will reach toward the sophistication of Earth. Still, as long as the supply chain is incomplete and we are sending things from Earth, we will be sending the lightest and most sophisticated things we can to be combined with the crude things made in space, and so the advances we’ve made since the 1980’s will indeed reduce the bootstrapping cost.

This is the second in a three-part series about building a space base. Yesterday: Why mine on the moon or an asteroid? Tomorrow: Making remote robots smart.