Boeing has unveiled the advanced new lightweight spacesuits that astronauts will sport as passengers aboard the company’s CST-100 Starliner space taxi during commercial taxi journey’s to and from and the International Space Station (ISS) and other low Earth orbit destinations.

The signature ‘Boeing Blue’ spacesuits will be much lighter, as well as more flexible and comfortable compared to earlier generations of spacesuits worn by America’s astronauts over more than five decades of human spaceflight, starting with the Mercury capsule to the latest gear worn by Space Shuttle astronauts.

“The suit capitalizes on historical designs, meets NASA requirements for safety and functionality, and introduces cutting-edge innovations,” say NASA officials.

The suits protect the astronauts during both launch and reentry into the Earth’s atmosphere during the return home.

Indeed, Chris Ferguson, a former NASA Space Shuttle Commander who now works for Boeing as a Starliner program director, helped reveal the ‘Boeing Blue’ spacesuits during a Facebook live event, where he modeled the new suit.

“We slogged through some of the real engineering challenges and now we are getting to the point where those challenges are largely behind us and it’s time to get on to the rubber meeting the road,” Ferguson said.

The suits offer superior functionality, comfort and protection for astronauts who will don them when crewed Starliner flights to the space station begin as soon as next year.

At roughly half the weight (about 10 pounds vs. 20 pounds) compared to the launch-and-entry suits worn by space shuttle astronauts, crews look forward to wearing the ‘Boeing Blue’ suits.

“Spacesuits have come in different sizes and shapes and designs, and I think this fits the Boeing model, fits the Boeing vehicle,” said Chris Ferguson.

Among the advances cited are:

• Lighter and more flexible through use of advanced materials and new joint patterns

• Helmet and visor incorporated into the suit instead of detachable. The suit’s hood-like soft helmet sports a wide polycarbonate visor to give Starliner passengers better peripheral vision throughout their ride to and from space.

• A communications headset within the helmet also helps connect astronauts to ground and space crews

• Touchscreen-sensitive gloves that allow astronauts to interact with the capsule’s tablets screens overhead

• Vents that allow astronauts to be cooler, but can still pressurize the suit immediately

• Breathable, slip resistant boots

• Zippers in the torso area will make it easier for astronauts to comfortably transition from sitting to standing

• Innovative layers will keep astronauts cooler

“The most important part is that the suit will keep you alive,” astronaut Eric Boe said, in a statement. “It is a lot lighter, more form-fitting and it’s simpler, which is always a good thing. Complicated systems have more ways they can break, so simple is better on something like this.”

The astronauts help the designers to perfect the suits very practically by wearing them inside Starliner mock-ups, moving around to accomplish tasks, reaching for the tablets screens, and climbing in and out of the capsule repeatedly, says Boe “so they can establish the best ways for astronauts to work inside the spacecraft’s confines.”

“The spacesuit acts as the emergency backup to the spacecraft’s redundant life support systems,” said Richard Watson, subsystem manager for spacesuits for NASA’s Commercial Crew Program.

“If everything goes perfectly on a mission, then you don’t need a spacesuit. It’s like having a fire extinguisher close by in the cockpit. You need it to be effective if it is needed.”

Boe is one of four NASA astronauts that form the core cadre of astronauts training for the initial flight tests aboard either the Boeing Starliner or SpaceX Crew Dragon now under development as part of NASA’s Commercial Crew program.

The inaugural flight tests are slated to begin in 2018 under contract to NASA.

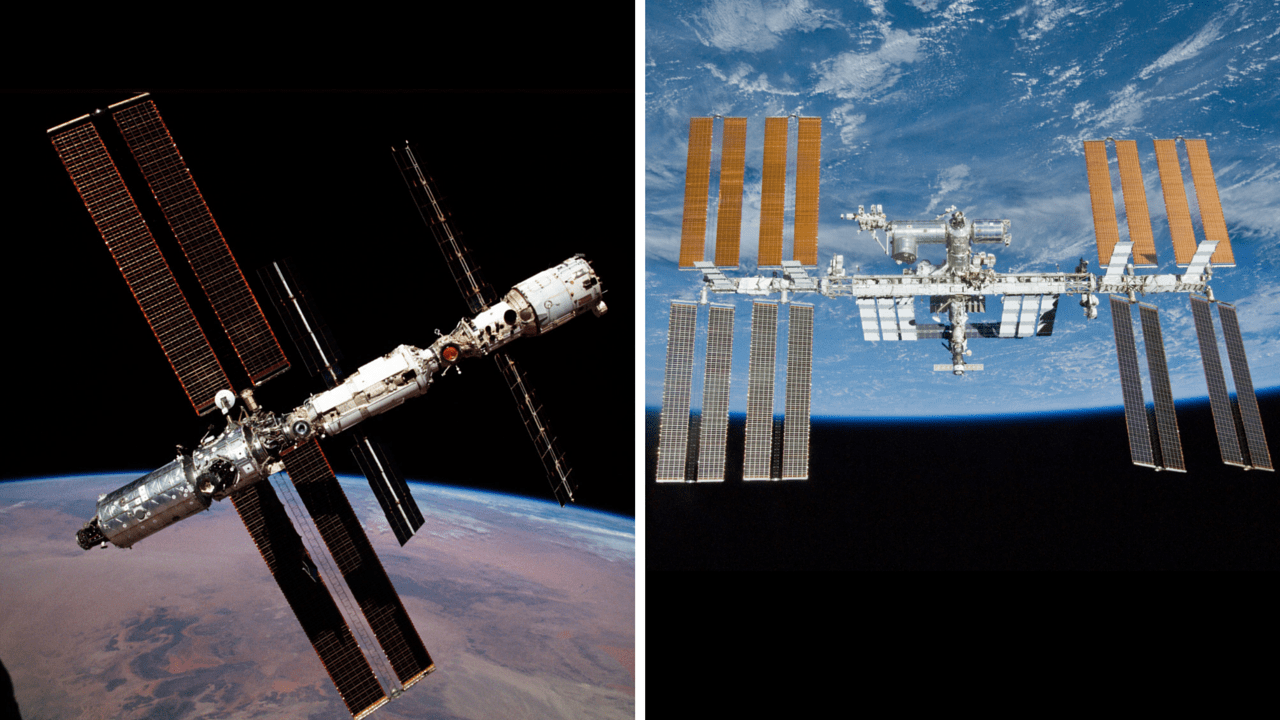

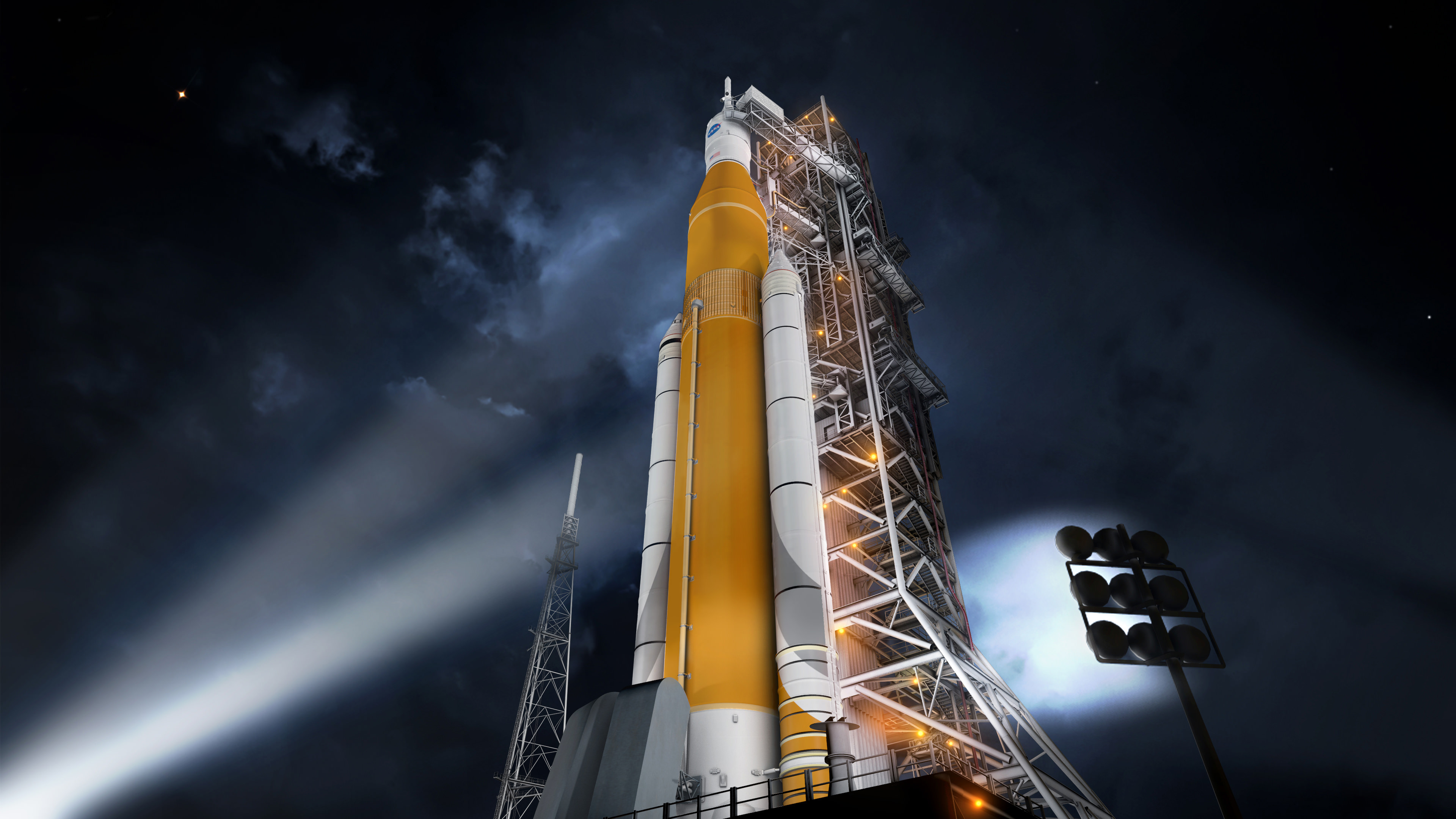

The procedure on launch day will be similar to earlier manned launches. For Starliner, however, the capsule will launch atop a United Launch Alliance Atlas V rocket – currently being man-rated.

Astronauts will don the new ‘Boeing Blue’ suit in the historic Crew Quarters. The will ride out to the rocket inside an astrovan. After reaching Space Launch Complex 41, they will take the elevator up, stride across the recently installed Crew Access Arm and board Starliner as it stands atop a United Launch Alliance Atlas V rocket.

The first test flight will carry a crew of two. Soon thereafter the crew size will grow to four when regular crew rotation flights to the ISS starting as soon as 2019.

“To me, it’s a very tangible sign that we are really moving forward and we are a lot closer than we’ve been,” Ferguson said. “The next time we pull all this together, it might be when astronauts are climbing into the actual spacecraft.”

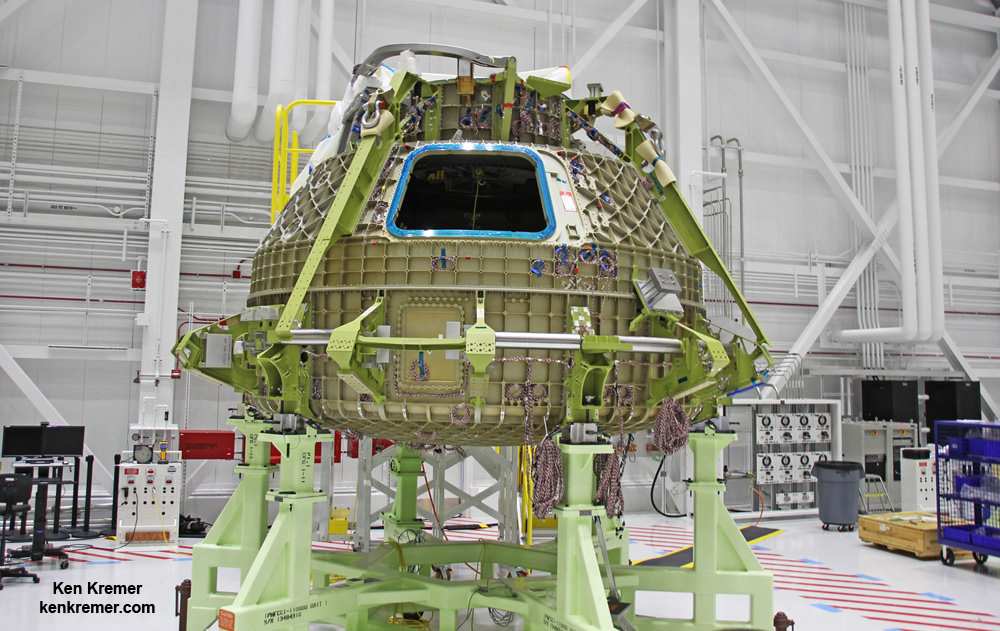

Boeing is currently manufacturing the Starliner spacecraft at the company’s Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in Florida.

Stay tuned here for Ken’s continuing Earth and planetary science and human spaceflight news.