NASA WALLOPS ISLAND, VA – The 1st operational Cygnus cargo spacecraft slated to ferry crucial supplies to the International Space Station (ISS) under a commercial contract with NASA, has been delivered to NASA’s Wallops Flight Facility in Virginia.

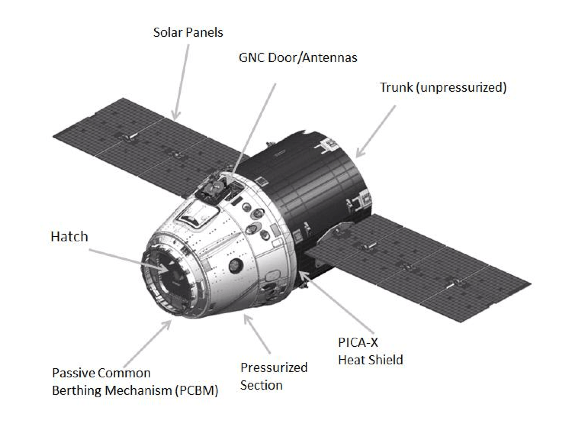

The privately built Cygnus Pressurized Cargo Module (PCM) was developed by Orbital Sciences Corp. & Thales Alenia Space under the Commercial Resupply Services (CRS) cargo transport contract with NASA.

Universe Today took an exclusive look at the unmanned Cygnus cargo carrier housed inside the high bay facility where the vehicle is being processed for flight during a visit at NASA Wallops.

This Cygnus transport vessel is scheduled to lift off atop an Antares rocket bound for the ISS from the Wallops Island launch site towards the end of this year.

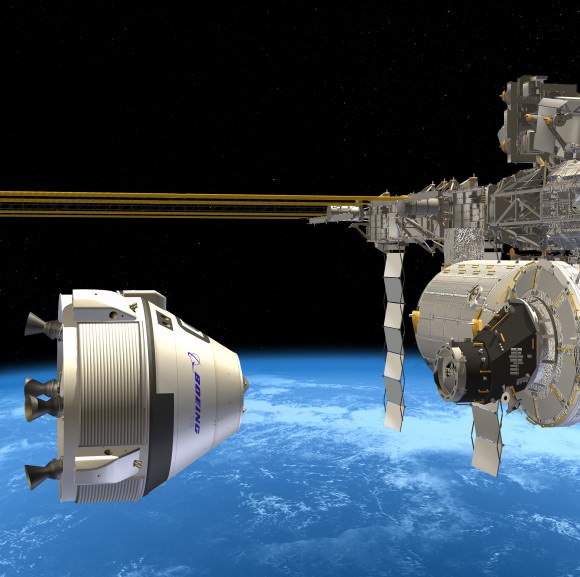

Cygnus is an essential lifeline to stock the station with all manner of equipment, science experiments, food, clothing, spare parts and gear for the international crew of six astronauts and cosmonauts.

The Cygnus PCM is manufactured by Thales Alenia Space at their production facility in Turin, Italy under a subcontract from Orbital.

The design is based on the Multi Purpose Logistic Module (MPLM) space shuttle cargo transporter.

The standard version has an internal volume of 18.9 cubic meters and can carry a total cargo mass of 2000 kg.

It was encased inside a special shipping container and flown from Italy to the US aboard an Antonov An-124 aircraft on July 17. The massive An-124 is the world’s second largest operating cargo aircraft.

After unloading from the An-124 and movement into a clean room high bay at Wallops Processing Building H-100, the shipping crate’s cover was raised using a 20 ton bridge crane. The PCM was unloaded and likewise gently craned over to an adjacent high bay work stand for flight processing.

Approximately a month and a half before launch, technicians mate the Cygnus PCM to the Service Module (SM) which houses the spacecraft’s avionics, propulsion and power systems and propels the combined vehicle to berth at the ISS.

The Cygnus SM is built by Orbital at their manufacturing facility in Dulles, VA., and shipped to Wallops for integration with the PCM in the processing building.

This particular vehicle is actually the second PCM bound for the ISS, but will be the first of eight operational cargo delivery runs to the space station over the next few years.

The first PCM to fly is set to blast-off on a Demonstration Mission (COTS 1) to the ISS in some six weeks on Sept. 14 atop Orbital’s privately developed Antares rocket. It is also in the midst of flight processing at Wallops inside a different building known as the Horizontal Integration Facility (HIF) where it is integrated with the Antares rocket.

Orbital says the Cygnus Demo vehicle is already fueled and will be loaded with about 1550 kg of cargo for the station crew.

The purpose of the demonstration flight is to prove that the unmanned spacecraft can safely and successfully rendezvous and dock with the orbiting outpost. The flight objectives are quite similar to the initial cargo delivery test flights successfully accomplished by Orbital’s commercial rival, SpaceX.

All of Orbital’s ISS cargo resupply missions will occur from the Mid-Atlantic Regional Spaceport’s (MARS) pad 0A at Wallops.

This past spring on April 21, Orbital successfully launched the 1st test flight of the Antares rocket. Read my articles here and here.

Orbital’s Antares/Cygnus system is similar in scope to the SpaceX Falcon 9/Dragon system.

Both firms won lucrative NASA contracts to deliver approximately 20,000 kilograms each of supplies and science equipment to the ISS during some 20 flights over the coming 3 to 4 years.

The goal of NASA’s CRS initiative is to achieve safe, reliable and cost-effective transportation to and from the ISS and low-Earth orbit (LEO) as a replacement for NASA’s now retired Space Shuttle Program.

Orbital’s contract with NASA for at least eight Antares/Cygnus resupply missions to the ISS is worth $1.9 Billion.

…………….

Learn more about Cygnus, Antares, LADEE, Mars rovers and more at Ken’s upcoming lecture presentations

Aug 12: “RockSat-X Suborbital Launch, LADEE Lunar & Antares Rocket Launches from Virginia”; Rodeway Inn, Chincoteague, VA, 8 PM